GaN-based power diode and preparation method thereof

A power diode and bottom electrode technology, applied in the field of GaN-based power diodes and their preparation, can solve problems such as high process difficulty and process complexity, achieve good reliability, high reverse breakdown voltage, and avoid the degradation of device performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

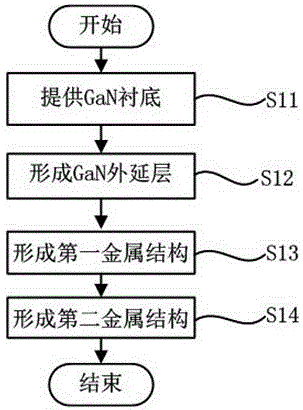

[0048] 在GaN基功率二极管制备方法的另一实施例中,如流程 Figure 9 shown, including the following steps:

[0049] 步骤S21,提供GaN衬底20。优选为n型GaN衬底,掺杂浓度大于10 18 cm -3 .

[0050] 步骤S22,在GaN衬底20上形成GaN外延层21。例如,采用金属有机物化学气相淀积法(MOCVD)外延20µm厚的n型GaN漂移层, 掺杂浓度优选为2×10 16 cm -3 .

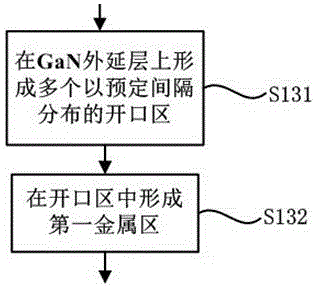

[0051] 步骤S23,形成第一金属层22并对其进行图形化,形成第一金属结构23,具体包括如下步骤:

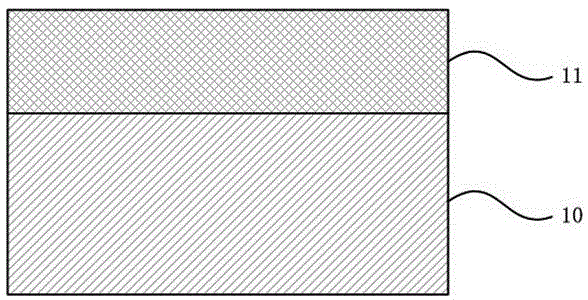

[0052] 步骤S231,在GaN外延层21上形成第一金属外延层22,所得结构如 Figure 10 shown;

[0053] 步骤S232,对第一金属外延层22进行图形化,使部分所述GaN外延层暴露,形成多个以预定间隔分布的第一金属结构23,所得结构如 Figure 11 shown.

[0054] 步骤S24,在第一金属结构23上以及GaN外延层21上形成第二金属结构24,与GaN外延层21形成低势垒肖特基接触,所得结构如 Figure 12 shown. 具体地,例如,悬涂正性光刻胶,曝光出顶部电极区域。 然后,在器件顶部蒸镀0.5 µm厚度的与GaN外延层形成低势垒肖特基的金属,优选为Ti / Au,去胶后获得第二金属结构24。

[0055] 优选地,如流程 Figure 9 所示,还包括底部电极形成步骤S25,在步骤S21前执行步骤S25,即在GaN衬底20背面形成底部电极25,与GaN衬底形成欧姆接触。具体地,例如淀积蒸镀钛 / 金金属,快速热退火处理后形成欧姆接触,所得结构如 Figure 13 shown. It should be understood that Figure 9 中所示的具体步骤提供了根据本发明的实施方案的制备GaN基功率二极管的特定方法。 根据可替代的实施方案也可以执行其他顺序的步骤。 例如,本发明的可替代的实施方案可以以不次序执行以上所概括的步骤。 also, Figure 9 中所示的单独步骤可以包括可以以各种次序执行的多个子步骤,只要适合于单独步骤即可。此外,根据特定的应...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com