Quality evaluating system for welding parameter of aluminum alloy spiral pipe

A technology for welding parameters and quality evaluation, applied in welding equipment, welding/welding/cutting items, metal processing, etc., can solve problems such as the inability to weld different grades of aluminum alloys, and the unsuitability of submerged arc automatic welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

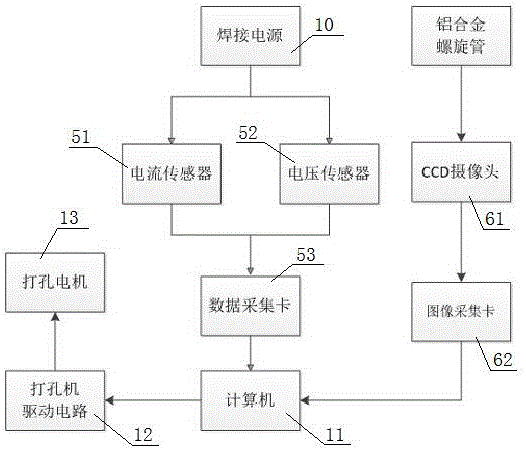

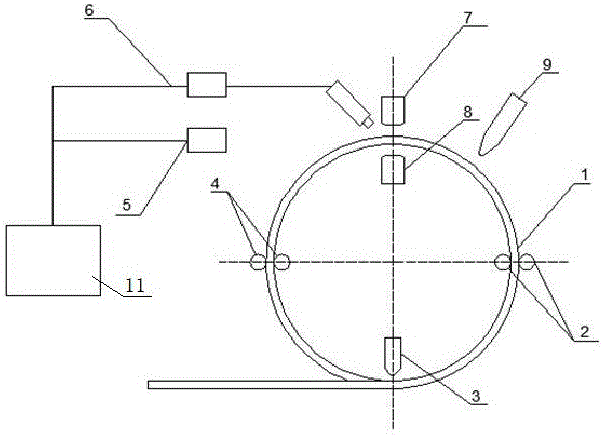

[0009] Such as figure 1 , 2 As shown, the aluminum alloy spiral pipe welding machine is equipped with a spiral pipe blank rolling device 1, two sets of rotating rollers 2, 4, a TIG welding torch 3, a first plasma welding torch 7, a second plasma welding torch 8, and a robot on the frame. Automatic punching machine 9, image acquisition system 6 and welding parameter acquisition system 5.

[0010] Each welding torch is a robotic automatic welding torch. The TIG welding torch 3 is set at the six o'clock position of the frame, which is flat welding. The first plasma welding torch 7 and the second plasma welding torch 8 are both set at the twelve o'clock position of the frame. The plasma torch 7 is for flat welding, the second plasma torch 8 is for overhead welding, and two groups of rotating rollers 2, 4 are respectively arranged at three o'clock and nine o'clock positions of the frame. The robot automatic punching machine 9 positions can be adjusted, and it is set at the one o'...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com