Robotic automatic welding device for submerged arc welding in space arc path

A technology of automatic welding and submerged arc welding, which is applied to the device supporting electrode clips, welding equipment, welding accessories, etc., can solve the problems of no economic benefit, poor fusion, inability to realize arbitrary arc changes of the path, etc., and achieves manual labor intensity. The effect of reducing, improving welding quality and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] The detailed features and advantages of the present invention are described in detail below in the specific embodiments, the content of which is sufficient to enable any person skilled in the art to understand the technical content of the present invention and implement it accordingly, and according to the specification, claims and drawings disclosed in this specification , those skilled in the art can easily understand the related objects and advantages of the present invention.

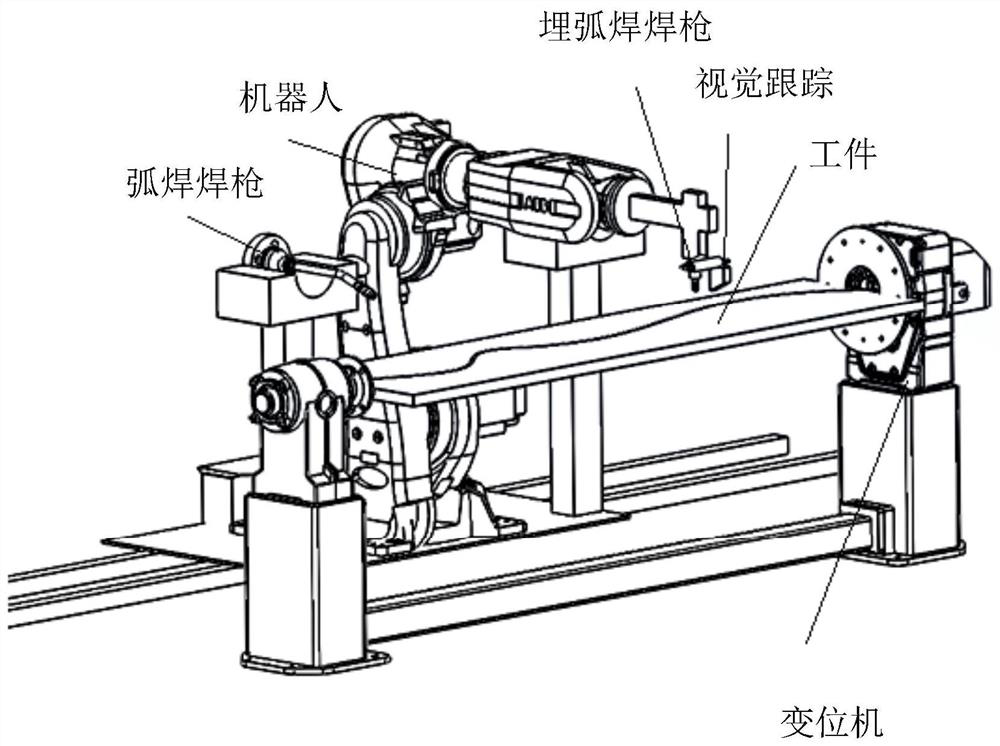

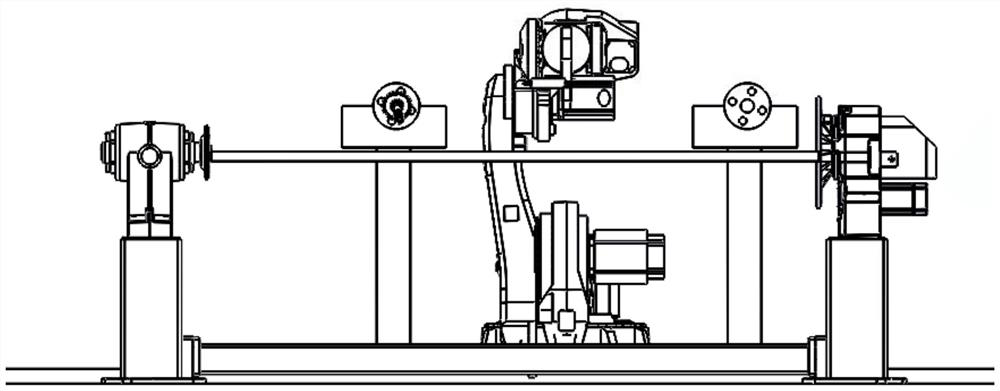

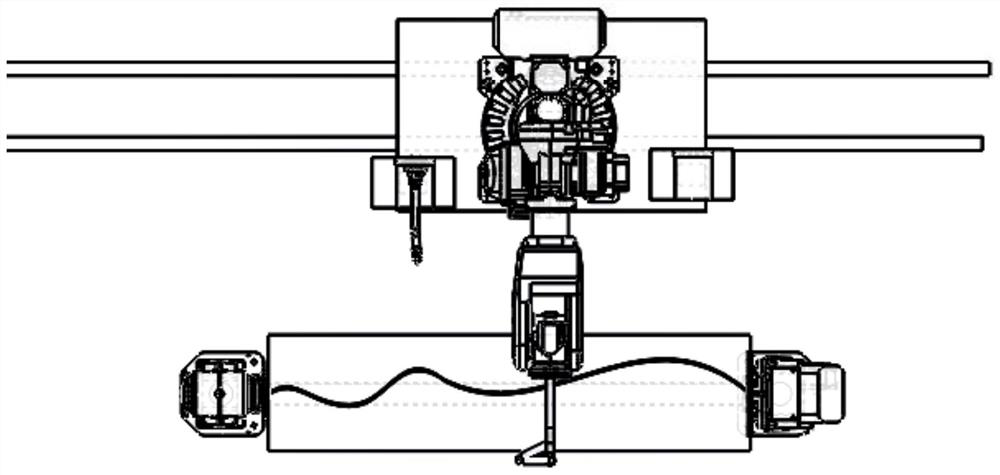

[0018] The present invention is mainly a robot welding device that can realize automatic welding of circular arc and space curve-like paths with multi-wire submerged arc with unclear roots. Tracking, automatic turn over and other functions. The device consists of a 6-axis manipulator, a quick automatic torch changer, a sliding table to expand the welding r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com