Two-gas re-firing boiler without a chimney

A chimney-free, gas-free technology, applied in the direction of combustion methods, combustion types, incinerators, etc., can solve the problems of ineffective recycling of waste gas, unfavorable energy saving and emission reduction, and large fuel consumption, and achieves easy construction and small footprint , the effect of eliminating carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be pointed out that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention. Therefore, the protection scope of the patent for the present invention should be based on the appended claims.

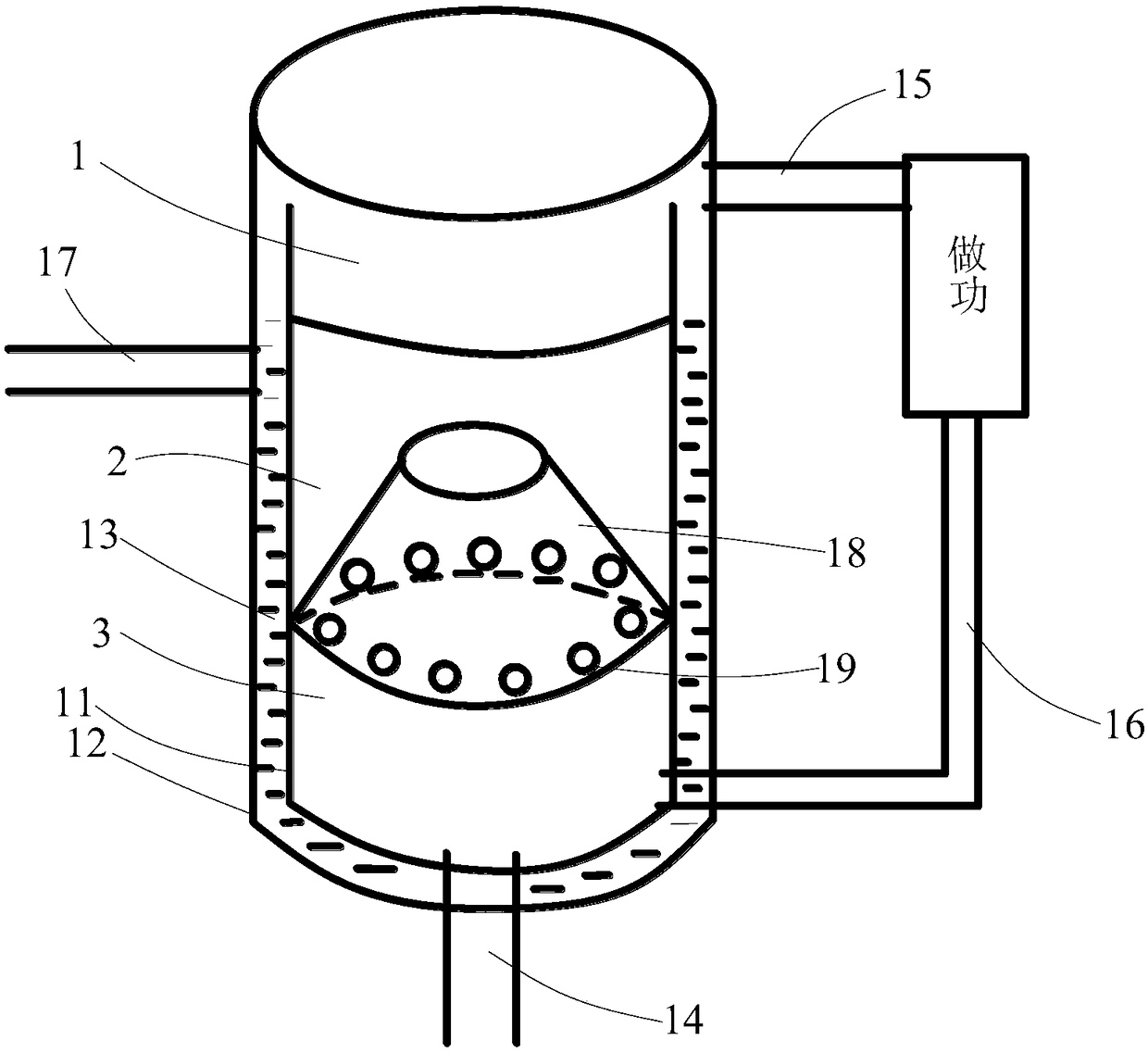

[0033] This embodiment provides an AMD smokeless boiler with repeated combustion of two gases, which is composed of a steam chamber 1 , an exhaust gas chamber 2 and a combustion chamber 3 .

[0034] The waste gas chamber 2 is arranged above the combustion chamber 3, and the shells of the waste gas chamber 2 and the combustion chamber 3 are composed of two layers of shells 11, 12 arranged inside and outside, and the interlayer 13 between the two layers of shells 11, 12 Injection of water; the bottoms of the two-layer shells 11 and 12 are provided with a large fire inlet 14 leading into the inner shell 11 for introducing flame an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com