Fracturing proppant filling assisted catalytic ignition combustion oil layer huff and puff oil recovery method

A fracturing proppant, catalytic ignition technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problem that the chemical catalytic ignition technology has not been popularized and applied, it is difficult to effectively and continuously function, and the formation near the wellbore is blocked to reduce the risk of oil layer permeability reduction, improve the success rate, and increase the light components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Reservoir 1 The depth of the reservoir is 800m; the thickness of the oil layer is 19.6m; the permeability of the oil layer is 610×10 -3 μm 2 ; Reservoir temperature 32°C; Crude oil viscosity 5100mPa.s; Crude oil density 0.9240g / cm 3 ; The oil saturation is 58.9%; Well J3 is the first production well in this reservoir, and the output of conventional cold recovery is lower than the economic limit output.

[0045] 1) Implement casing perforation completion on Well J3, the perforation interval is 17.6m, and the upper and lower sections of the oil layer are each avoided by 1m.

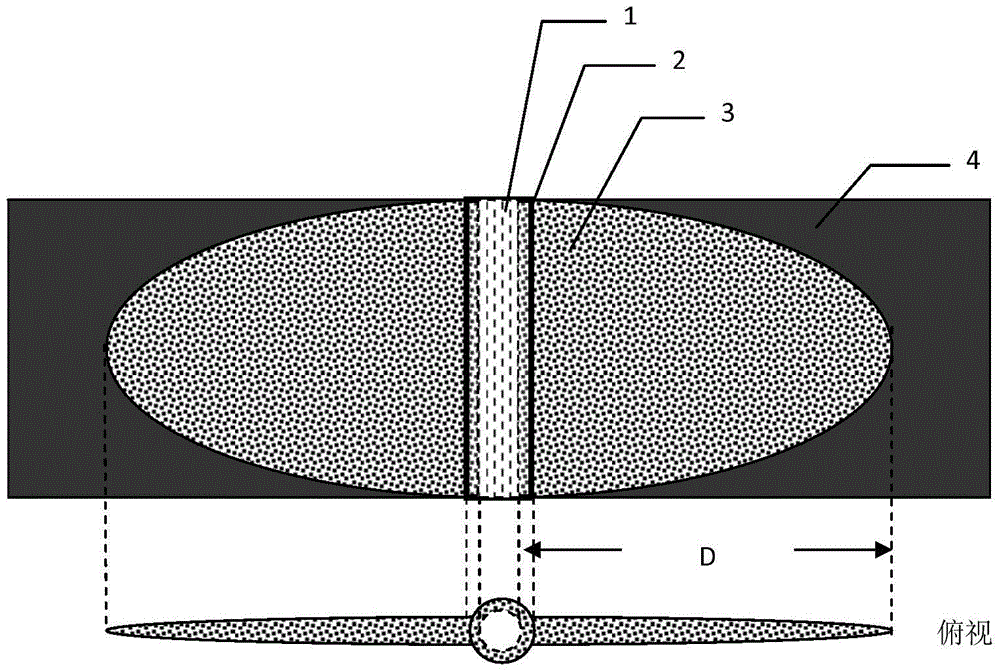

[0046] 2) Use hydraulic fracturing proppant filling technology to press out artificial fractures. The specific construction parameters are as follows: accumulatively add 40m of ceramsite with a particle size of 0.425mm to 0.850mm 3 , the ceramsite is mixed evenly with 40 liters of platinum / carbon catalyst with 4% platinum content before adding; the front liquid is 40m 3 ; Cross-linking sand carri...

Embodiment 2

[0053] Reservoir 2 The depth of the reservoir is 1200m; the thickness of the oil layer is divided into 3 small thin layers, with a total thickness of 11.2m; the permeability of the oil layer is 410×10 -3 μm 2 ; Reservoir temperature 30°C; Crude oil viscosity 4800mPa.s; Crude oil density 0.9220g / cm 3 ; Oil saturation 55.9%. Well J15 is the first production well in the reservoir, and conventional cold recovery has no production capacity.

[0054] 1) Carry out casing perforation completion on J15 well, and shoot all the oil layers;

[0055] Hydraulic fracturing proppant filling technology is used to press out artificial fractures. The specific construction parameters are as follows: accumulatively add 30m of ceramsite with a particle size of 0.425mm to 0.850mm 3 , the ceramsite is mixed evenly with 35 liters of palladium / carbon catalyst with 4% palladium content before adding; 3 ;Cross-linked sand-carrying fluid 85m 3 ; Displacement 3.2m 3 / min; during construction, the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com