A Generalized Modeling Method for Simulation of Dynamic Characteristics of Wet Desulfurization Tower

A dynamic characteristic and wet desulfurization technology, which is applied in the field of simulation modeling, can solve problems such as the difficulty of generalizing the simulation model of the dynamic characteristics of the desulfurization tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

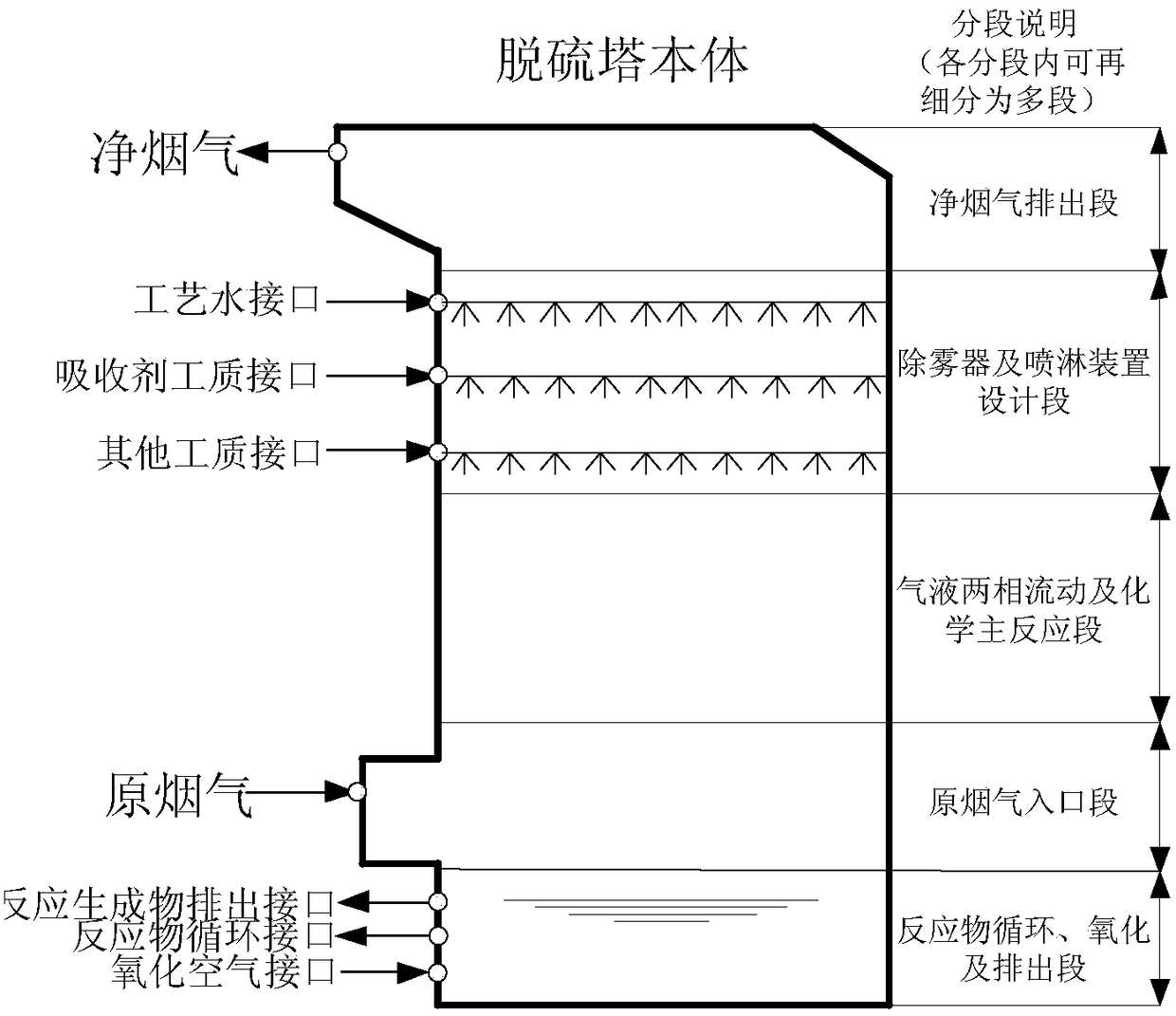

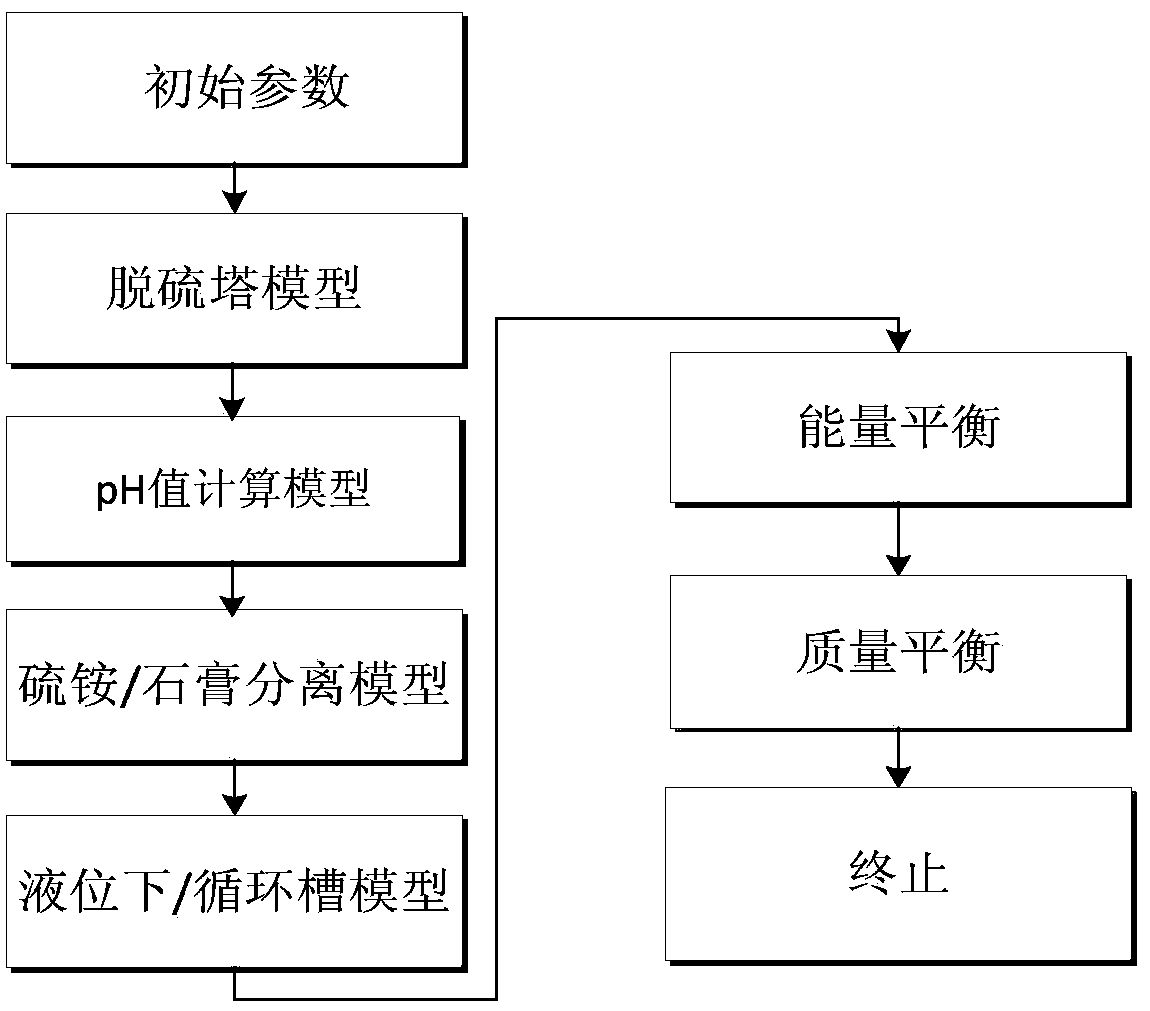

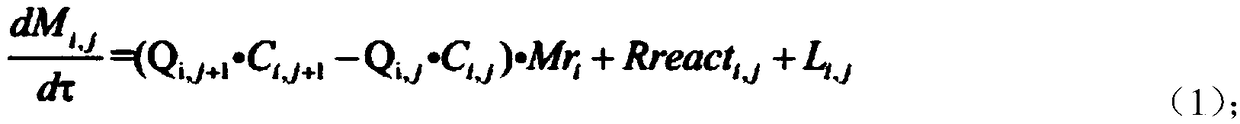

[0053] Model assumptions: For the convenience of calculation, the following assumptions are made on the mathematical model based on the operation process and theoretical analysis of the desulfurization tower: SO in the flue gas 2 The mass transfer rate with the absorption liquid is controlled by the gas film and the liquid film; the entire chemical reaction is completed in the liquid film; the droplets on any interface of the desulfurization tower are evenly distributed and the same size, and the droplets remain spherical during the falling process; the desulfurization tower The two phases of gas and liquid in the interior are one-dimensional flow; the ionization of the liquid droplets and the material under the liquid level of the desulfurization tower is completed instantaneously; the mixing of the material under the liquid level is completed instantaneously.

[0054] Desulfurization tower absorption reaction model: This model simulates two wet desulfurization modes, namely a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com