Comminuting tool

A technology of crushing tools and tools, which is applied in the direction of household appliances, other household appliances, household components, etc., can solve the problem that cutting tools cannot be completed, and achieve the effect of optimizing supply, improving efficiency, and good mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

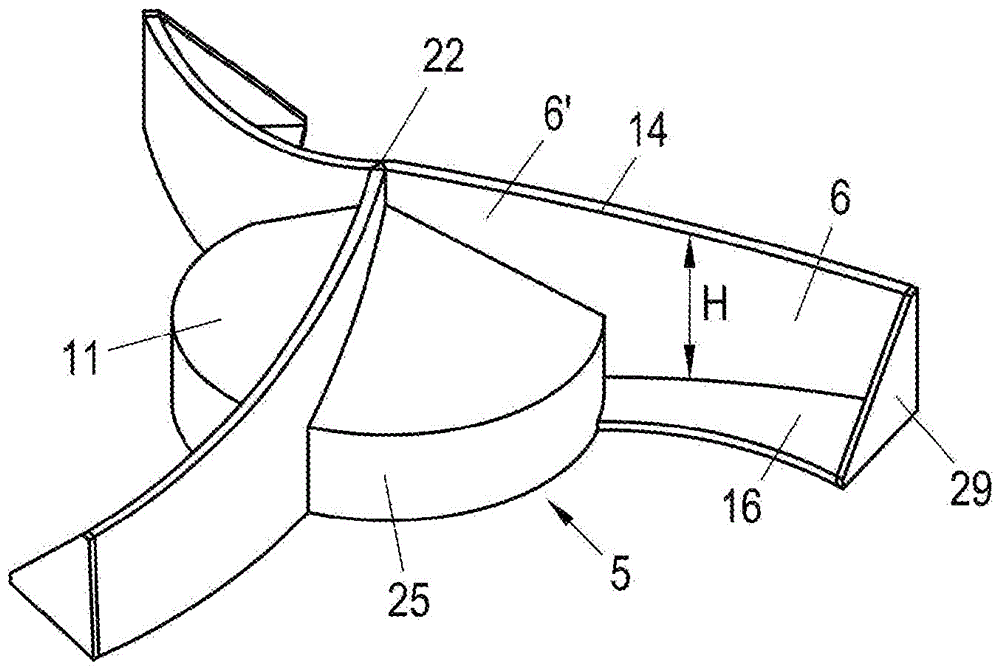

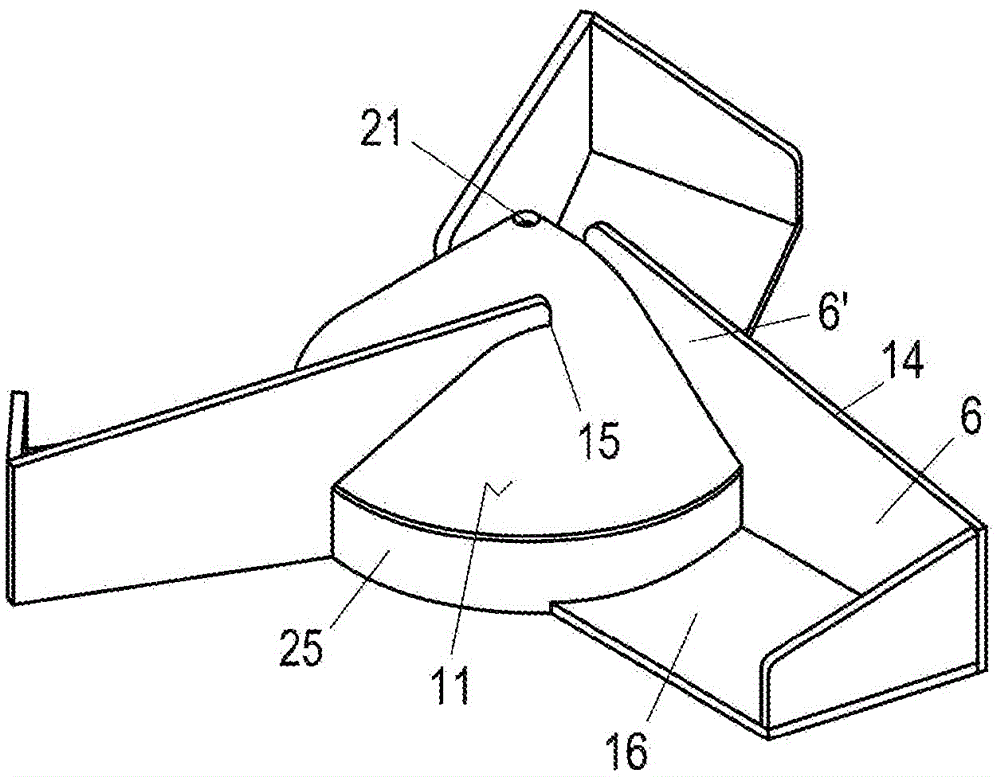

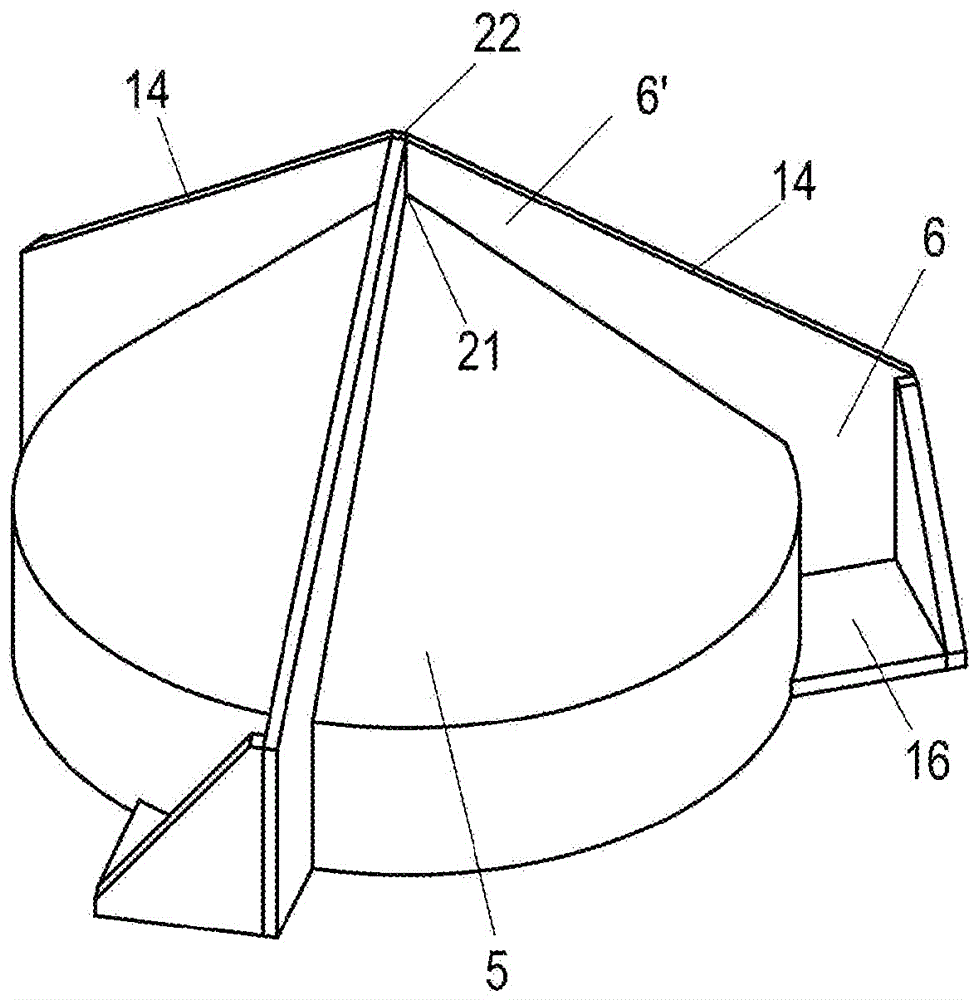

[0047] figure 1 A container 9 is shown, in which a comminution tool according to the invention is supported, which can be driven in a rotational movement by a shaft 17 of a motor M about a vertical axis of rotation B of the container 9 . In its central region, the disk-shaped support part 1 carries a deflection part 5 which is advantageously designed rotationally symmetrically with respect to the axis of rotation B of the support part 1 . The conveying blade 6 extends from the deflection element 5 in the direction of the edge 7 of the carrier part 1 , at the end region 29 of which the tool 4 is connected. In the present case, the deflector 5 also carries the conveying blades 6 ′ or the conveying blades 6 ′ are arranged above the deflector 5 . In the present case, the conveying blade 6 ′ is formed in one piece with the conveying blade 6 .

[0048] The conveying blade 6 ′ arranged above the deflector 5 and the conveying blade 6 connected to said conveying blade 6 ′ can proceed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com