Forced vibration inter-cultivation and weeding machine

A technology of forced vibration and weeding machine, which is applied in the fields of soil preparation machinery, weed elimination equipment, agricultural machinery and implements, etc. It can solve the problems of many working procedures, low working efficiency, affecting plant root growth and crop yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

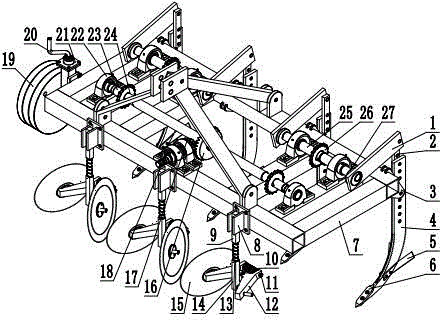

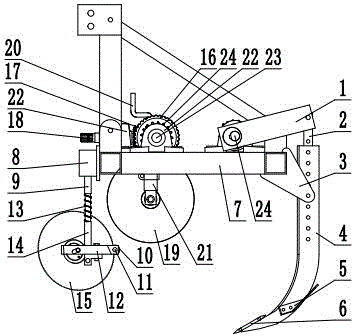

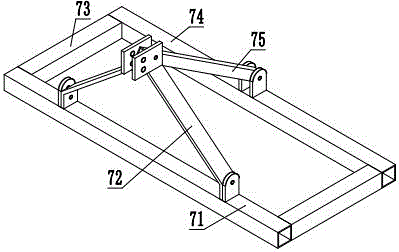

[0016] Refer to attached Figure 1~4 , the present invention comprises frame 7 and forced vibration device, and described frame 7 is made of front beam 71, front tie bar 72, crossbeam 73, back beam 74 and rear tie bar 75, and front tie bar 72 is connected with front beam 71, and back tie bar 75 The front end is connected with the upper end of the front tie rod 72, the rear end of the back tie rod 75 is connected with the back beam 74, and the back beam 74 is connected with the front beam 71 by the crossbeam 73; the forced vibration device consists of a large bevel gear 16, a small bevel gear 17, a power input shaft 18, Bearing seat 22, main transmission shaft 23, driving gear 24, driven eccentric shaft 25, driven gear 26 and eccentric sleeve 27 constitute, bearing seat 22 is connected with front beam 71 of frame 7, and bearing seat 22 is provided with power input Shaft 18, small bevel gear 17 is connected with the rear end of power input shaft 18, large bevel gear 16 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com