A pounding system of a household type rice mill with germ preservation

A rice milling machine and rice technology, which is applied in the field of pounding system, can solve the problems of hindering the use of rice machines, large temperature changes of rice, poor whiteness and brightness of rice, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

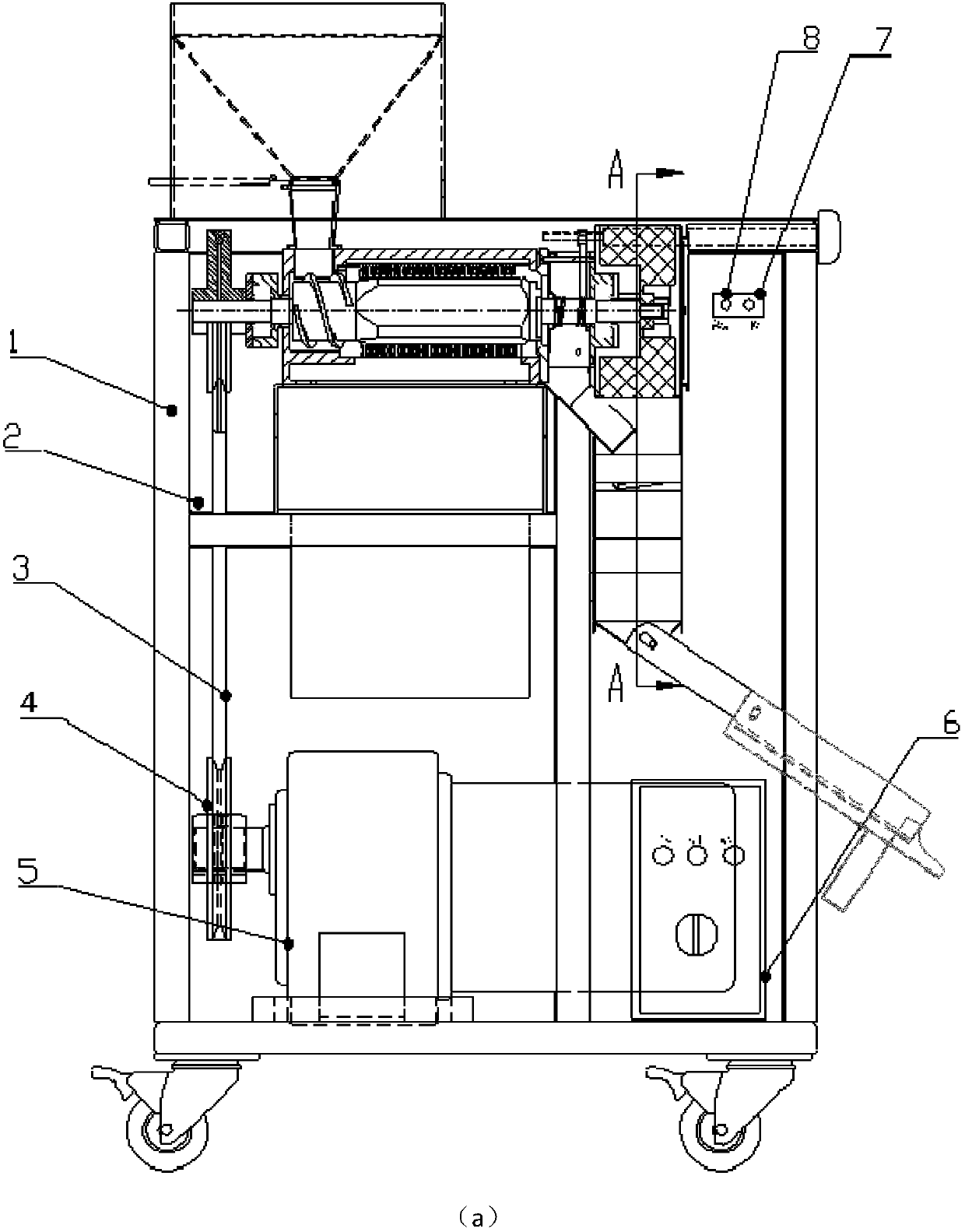

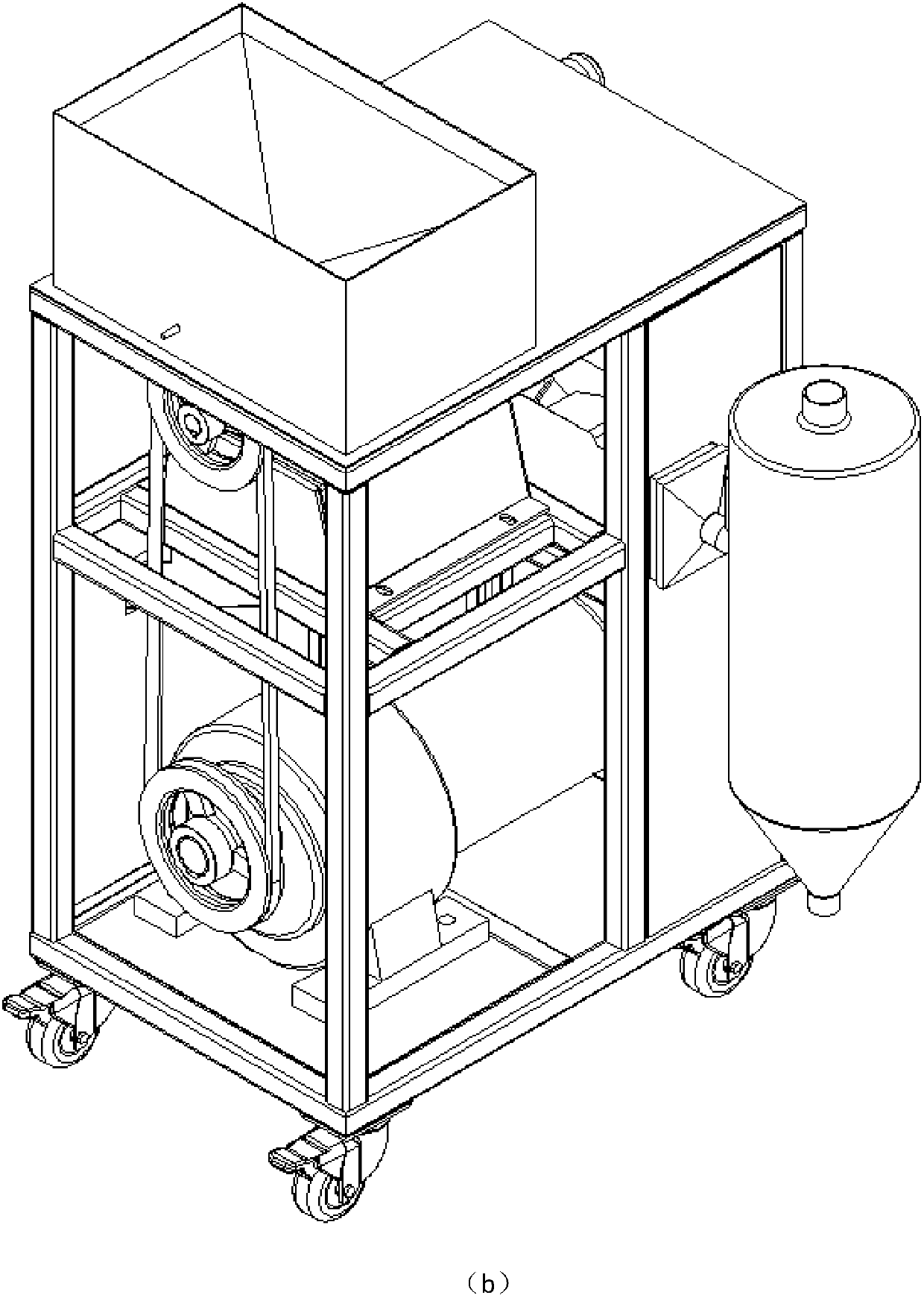

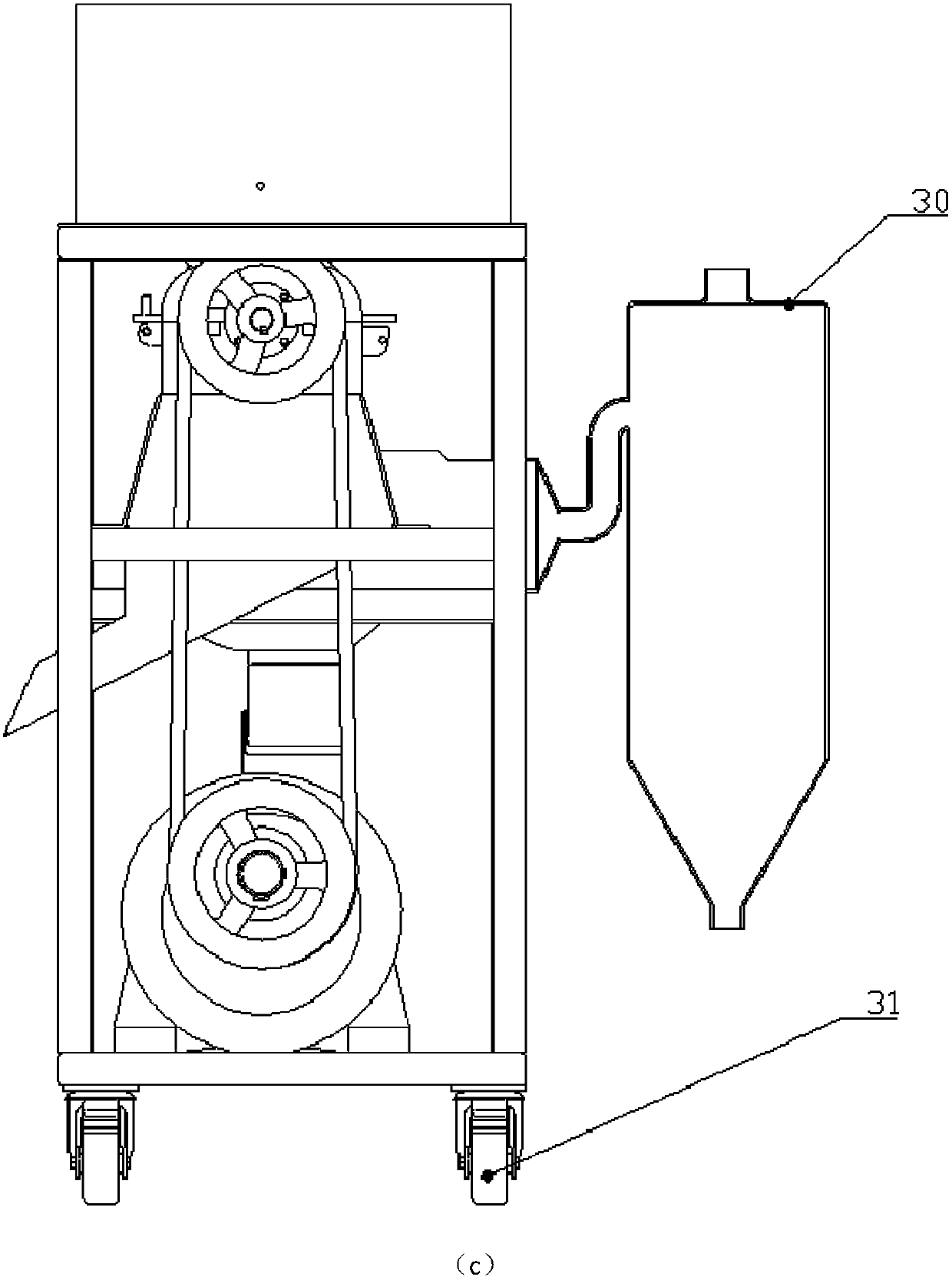

[0056] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0057] like Figure 1 to Figure 5 As shown, the present invention discloses a pounding system of a domestic rice germ preservation rice mill, comprising a screen frame 15, a combined mesh screen 29, two bearing blocks 14, a self-aligning bearing 12, a bearing cover 13, and a rice roller 25 , chaff hopper 16, discharge port 20, rice retaining plate adjustment lever 24, spring 26, rice retaining plate 28;

[0058]Wherein the sieve frame 15 is fixed on the rice mill shell, and the combined mesh screen 29 is fixed on the inside of the sieve frame 15, and the upper and lower parts of the combined mesh screen 29 are respectively combined with the upper and lower parts of the sieve frame 15 to form a hollow cavity; two The bearing housings 14 are respectively installed at both ends of the screen frame 15, and a self-aligning bearing 12 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com