Full-automatic machining production line for bamboo tubes

A fully automatic, production line technology, applied in sugarcane machining, mechanical equipment, etc., can solve problems such as low work efficiency, uneven inner surface, impact on product quality, etc., and achieve high cutting surface accuracy, smooth surface, and reasonable structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

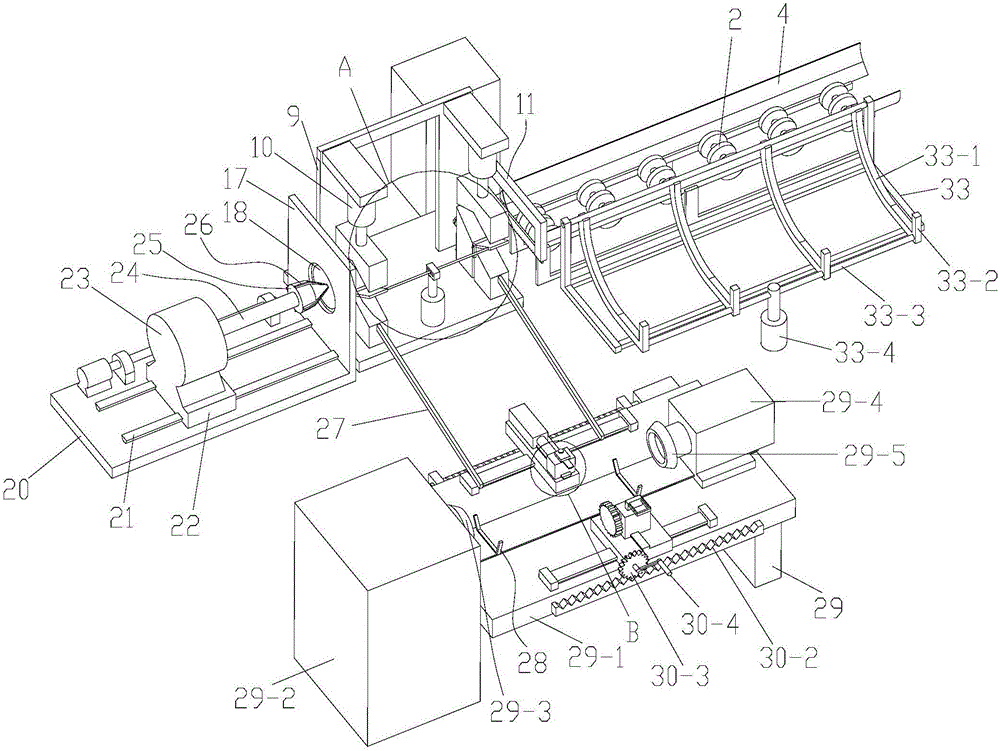

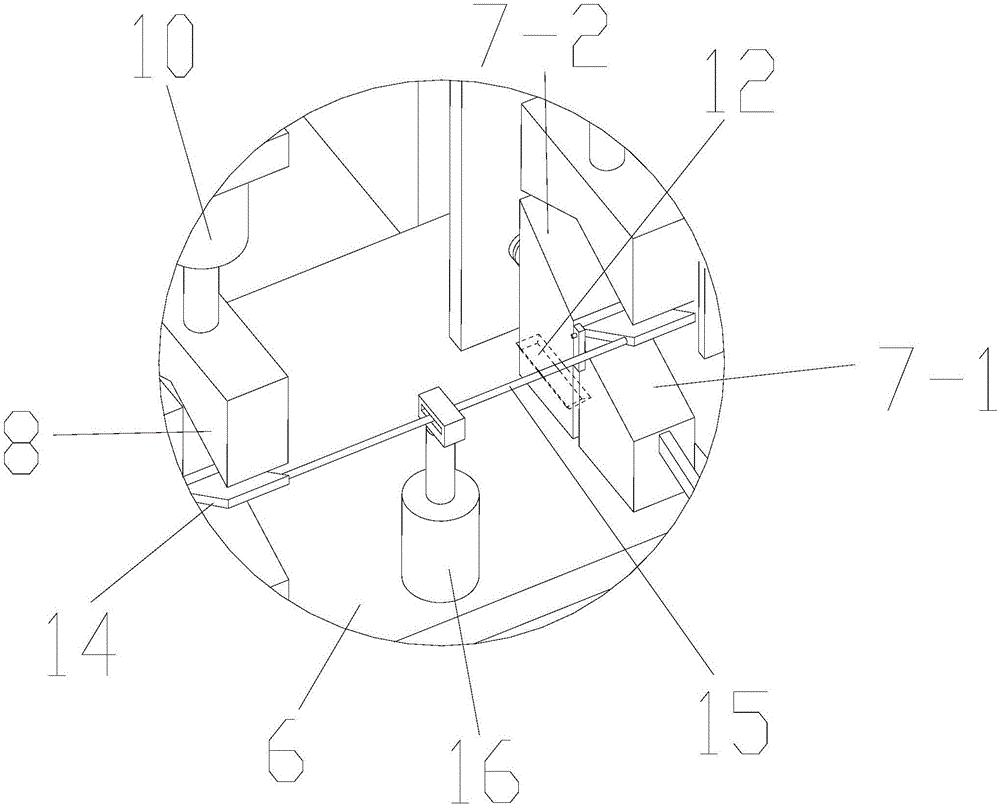

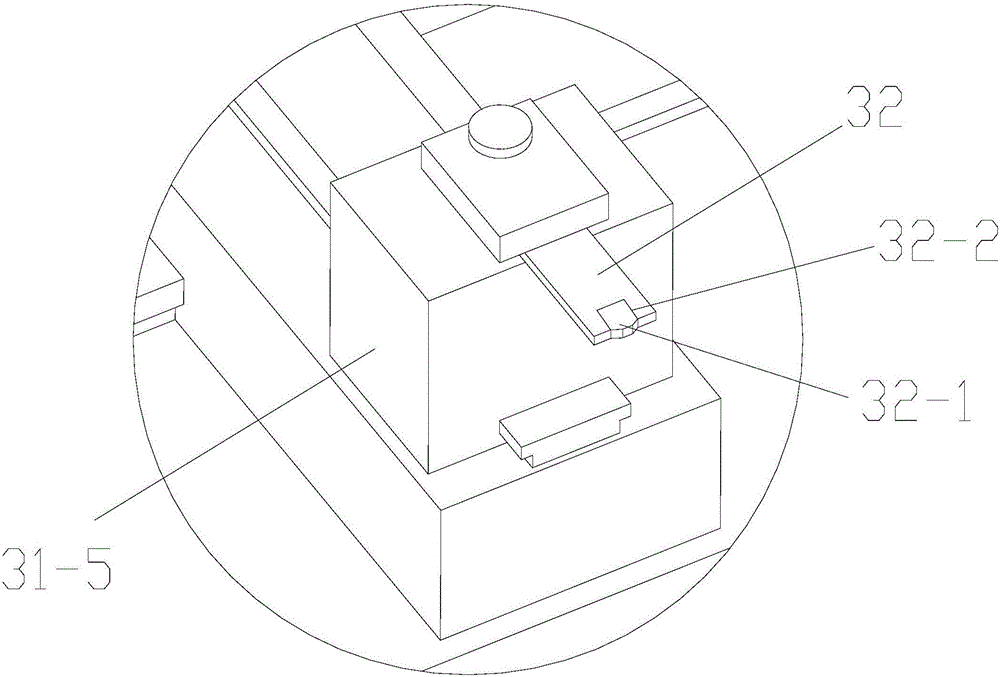

[0023] Combine below Attached picture The present invention is described further:

[0024] refer to Attached picture : In the present embodiment, the full-automatic production line for processing bamboo tubes includes a conveying frame 1, a row of conveying wheels 2 is installed on the conveying frame 1, the conveying wheels 2 are connected with a conveying motor 3, and inclined side baffles are respectively installed on the front and rear sides of the conveying frame 1 4. A storage rack 33 is installed on the front side of the conveyor frame 1, and a set of storage rods 33-1 are installed on the storage rack 33. The rear end of the storage rod 33-1 is located above the side baffle 4 and is connected to the storage rack 33 in rotation. On, the front end of storage rod 33-1 is equipped with blocking rod 33-2, and the front end of storage rod 33-1 is connected by fixed rod 33-3, and fixed rod 33-3 is installed on the support cylinder 33-4.

[0025] Wherein the outlet of conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com