Method for modifying and thinning of deformable aluminum alloy

A deformed aluminum alloy, metamorphic and refined technology, which is applied in the field of chemical metallurgy, can solve the problems of poor mechanical properties, unstable metamorphic and refined effects, and easy decay, and achieve the effect of not easy to decay, stable refining effect, and increased physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

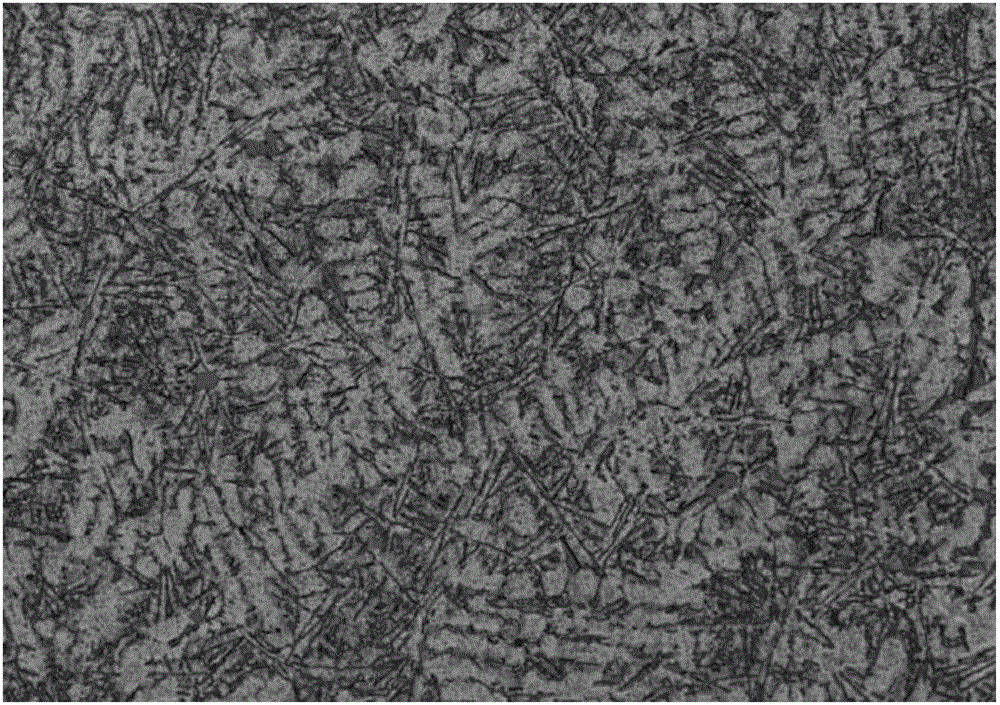

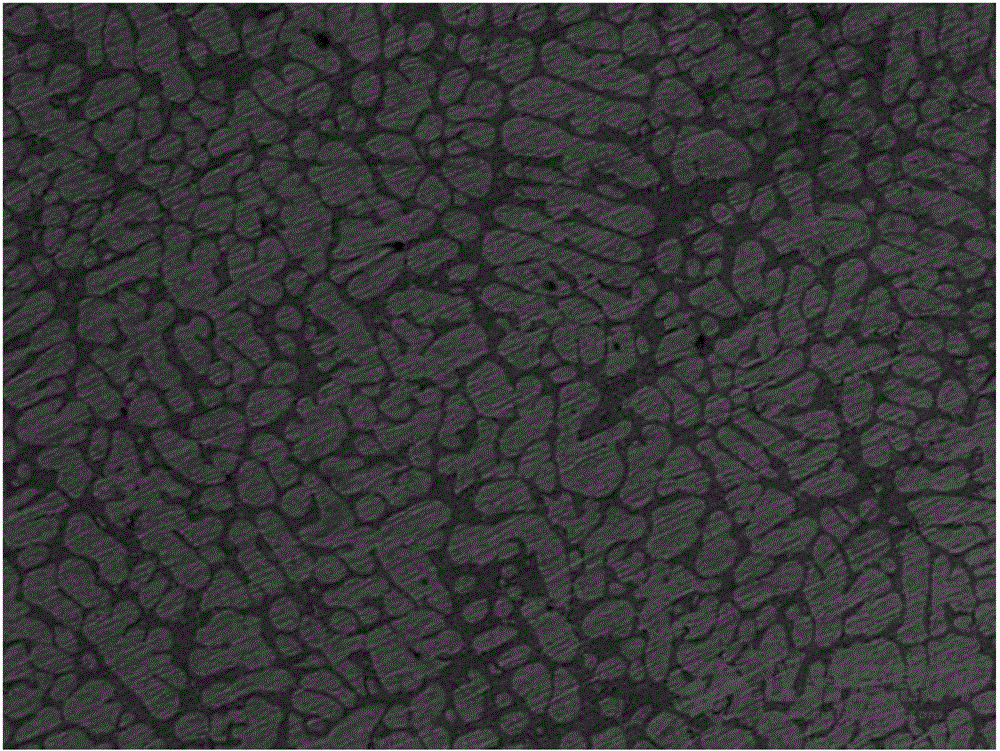

Image

Examples

Embodiment 1

[0035] A method for modifying and refining a deformed aluminum alloy, comprising the following steps:

[0036] (1) Smelting, put the cast aluminum alloy material into the smelting furnace for smelting, and add 25% SiC by weight and 75% CaC by weight during the smelting process 2 After adding the compound deoxidizer for 10 minutes, remove the scum above the solution to obtain the deoxidized aluminum alloy solution;

[0037] (2) Refining. When the temperature in the furnace reaches 680°C, the Ca-Al-Si-Li-Fe refining agent is blown into the melting chamber through nitrogen rotation, and then kept at a temperature of 680°C for 10 minutes to remove the aluminum alloy solution. Gas and non-metallic impurities, wherein the mass ratio of refining agent to aluminum alloy is 0.05:1;

[0038] (3) Modification, add a modification agent composed of Al-5Ti-B master alloy and Al-10RE master alloy in the tempering chamber, and carry out modification treatment to the aluminum alloy solution. Th...

Embodiment 2

[0047] A method for modifying and refining a deformed aluminum alloy, comprising the following steps:

[0048] (1) Smelting, put the cast aluminum alloy material into the smelting furnace for smelting, and add 30% SiC by weight and 70% CaC by weight during the smelting process 2 Composite deoxidizer. After adding for 10 minutes, remove the scum above the solution to obtain a deoxidized aluminum alloy solution.

[0049] (2) Refining. When the temperature in the furnace reaches 700°C, the Ca-Al-Si-Li-Fe refining agent is blown into the melting chamber through nitrogen rotation, and then kept at a temperature of 700°C for 15 minutes to remove the aluminum alloy solution. Gas and non-metallic impurities, the mass ratio of refining agent to aluminum alloy is 0.07:1.

[0050] (3) Modification, adding a modification agent composed of Al-5Ti-B master alloy and Al-10RE master alloy in the tempering chamber to modify the aluminum alloy solution. The method of modification treatment i...

Embodiment 3

[0059] A method for modifying and refining a deformed aluminum alloy, comprising the following steps:

[0060] (1) Smelting, putting the cast aluminum alloy material into a smelting furnace for smelting, and adding 40% SiC by weight and 60% CaC by weight during the smelting process 2 After adding the compound deoxidizer for 10 minutes, remove the scum above the solution to obtain the deoxidized aluminum alloy solution.

[0061] (2) Refining. When the temperature in the furnace reaches 730°C, the Ca-Al-Si-Li-Fe refining agent is blown into the melting chamber through nitrogen rotation, and then kept at a temperature of 730°C for 10 minutes to remove the aluminum alloy solution. Gas and non-metallic impurities, the mass ratio of refining agent to aluminum alloy is 0.08:1.

[0062] (3) Modification, adding a modification agent composed of Al-5Ti-B master alloy and Al-10RE master alloy in the tempering chamber to modify the aluminum alloy solution. The method of modification tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com