Nanometer quantitative filter paper and production method thereof

A technology of quantitative filter paper and qualitative filter paper, which is applied in the field of filter paper and can solve the problems of paper thickness of quantitative filter paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

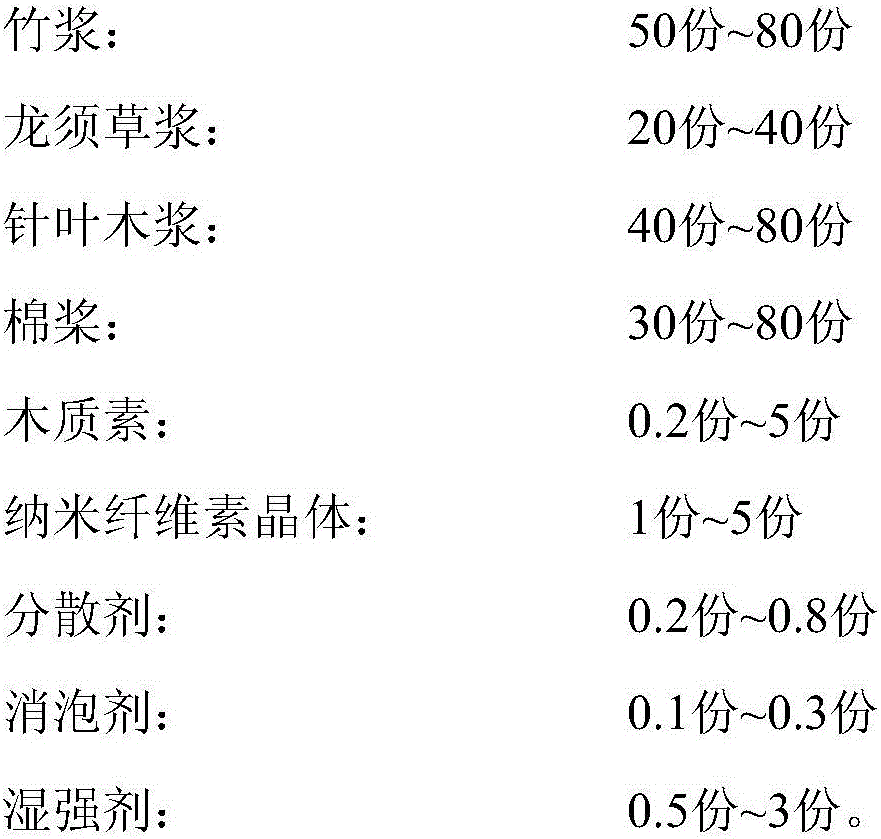

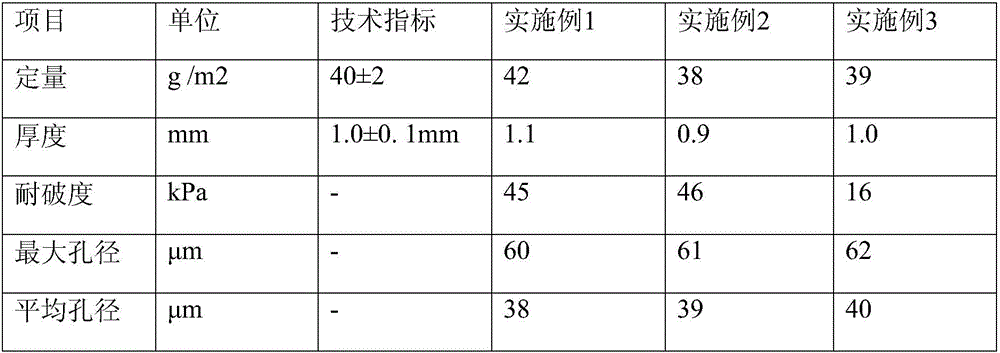

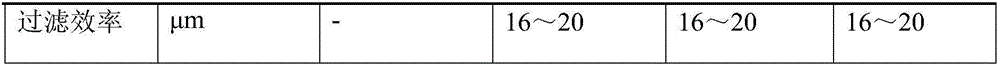

[0023] Nano-quantitative filter paper, in parts by weight, including bamboo pulp: 50 parts, asparagus pulp: 20 parts, coniferous wood pulp: 40 parts, cotton pulp: 30 parts, lignin: 0.2 parts, nanocellulose crystals: 1 part, dispersant: 0.2 parts, defoamer: 0.1 part, wet strength agent: 3 parts.

[0024] Described dispersant is polyoxyethylene; Described defoamer is butanol; Described bamboo pulp is the bamboo pulp that obtains through 200 mesh screens; Described bamboo pulp, asparagus pulp, coniferous wood pulp Both cotton and cotton paddles need to be treated with hydrochloric acid and hydrofluoric acid respectively, and the pulp obtained by washing with distilled water.

[0025] The preparation method of above-mentioned nanometer quantitative filter paper, comprises the steps:

[0026] 1) Slurries obtained by treating bamboo pulp, asparagus pulp, softwood pulp and cotton pulp with hydrochloric acid and hydrofluoric acid respectively, and washing with distilled water.

[00...

Embodiment 2

[0033] Nano-quantitative filter paper, in parts by weight, including bamboo pulp: 80 parts, asparagus pulp: 40 parts, coniferous wood pulp: 80 parts, cotton pulp: 80 parts, lignin: 5 parts, nanocellulose crystals: 5 parts, dispersant: 0.2 parts, defoamer: 0.3 parts, wet strength agent: 3 parts.

[0034] The dispersant is anionic polyacrylamide; the defoamer is silicone oil; the bamboo pulp is obtained through a 200-mesh screen; the bamboo pulp, asparagus pulp, softwood Both pulp and cotton paddle need to be treated with hydrochloric acid and hydrofluoric acid respectively, and the pulp obtained by washing with distilled water.

[0035] The preparation method of above-mentioned nanometer quantitative filter paper, comprises the steps:

[0036] 1) Slurries obtained by treating bamboo pulp, asparagus pulp, softwood pulp and cotton pulp with hydrochloric acid and hydrofluoric acid respectively, and washing with distilled water.

[0037] 2) Add water to the bamboo pulp, asparagus...

Embodiment 3

[0043] Nano-quantitative filter paper, in parts by weight, including bamboo pulp: 60 parts, asparagus pulp: 25 parts, coniferous wood pulp: 50 parts, cotton pulp: 60 parts, lignin: 2.5 parts, nanocellulose crystals: 3 parts, dispersant: 0.5 parts, defoamer: 0.2 parts, wet strength agent: 2.0 parts.

[0044] Described dispersant is polyoxyethylene; Described defoamer is pine oil; Described bamboo pulp is the bamboo pulp that obtains through 200 mesh screens; Described bamboo pulp, asparagus pulp, coniferous wood pulp Both cotton and cotton paddles need to be treated with hydrochloric acid and hydrofluoric acid respectively, and the pulp obtained by washing with distilled water.

[0045] The preparation method of above-mentioned nanometer quantitative filter paper, comprises the steps:

[0046] 1) Slurries obtained by treating bamboo pulp, asparagus pulp, softwood pulp and cotton pulp with hydrochloric acid and hydrofluoric acid respectively, and washing with distilled water. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com