Fabricated energy dissipation frame shear wall

A prefabricated and shear wall technology, applied in the field of building structural walls, can solve the problems of poor integrity of prefabricated buildings, poor seismic performance, and restrict the development of prefabricated buildings, so as to facilitate mass production and on-site assembly, and improve earthquake resistance The effect of strong performance and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in combination with technical solutions and with reference to the accompanying drawings.

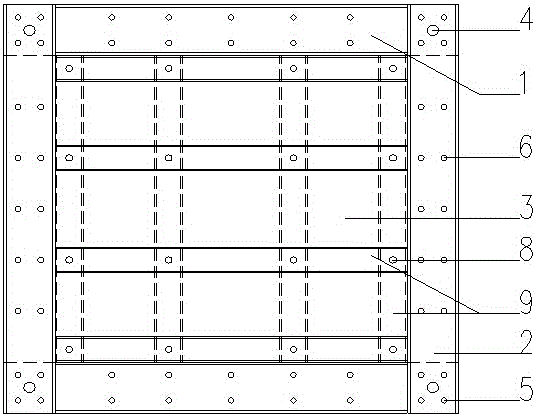

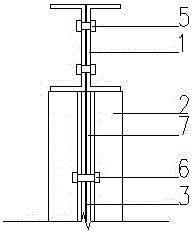

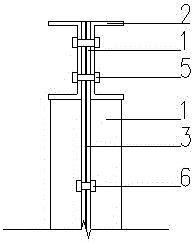

[0024] The assembled energy-dissipating frame shear wall proposed by the present invention is as figure 1 , figure 2 , image 3 shown.

[0025] The assembled energy-dissipating frame shear wall consists of frame beams, frame columns, steel plate walls 3, node pins 4, node bolts 5, frame bolts 6, stiffening bolts 8 and channel steel stiffeners 9, and is characterized in that: The frame beam is composed of two webs of beam channel steel 1; the frame column is composed of four webs in total of two column channel steel 2 and two inner backing plates 7; side, the frame columns are located on the left and right sides of the steel plate wall 3, sandwich the steel plate wall 3 in the middle, and pass through the frame bolts 6 on the frame beams and frame columns and the node pins 4 and node bolts at the joint positions of the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com