Down-hole speed increasing tool with axial impact function

A technology of axial impact and function, which is applied in drilling equipment, driving devices for drilling in boreholes, earthwork drilling and production, etc. It can solve the problems of easy damage of hydraulic impactor, low rock breaking efficiency of drill bit and low mechanical speed of penetration, etc. Achieve the effects of prolonging the service life, alleviating the stick-slip phenomenon of stuck drill, and increasing the ROP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

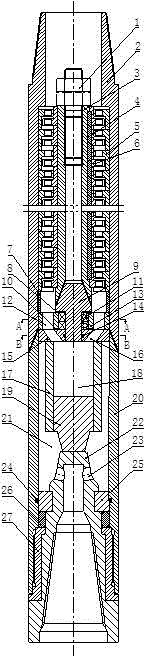

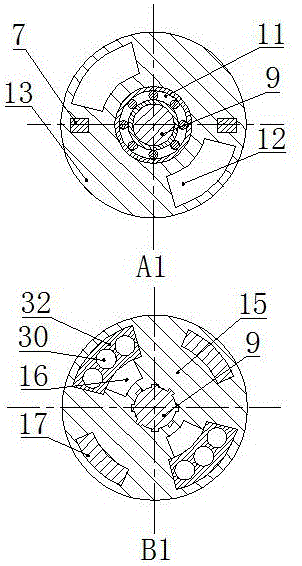

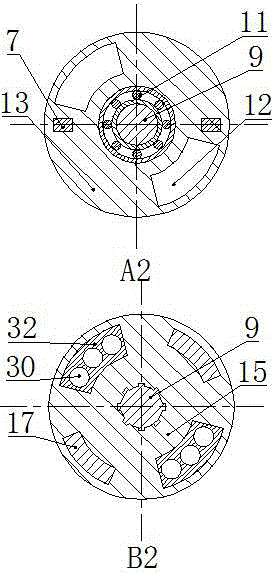

[0019] According to attached figure 1 As shown, the downhole speed-increasing tool with axial impact function consists of a nut (1), an upper casing (2), a turbine shaft (3), a flat key (4), a turbine stator (5), a turbine rotor (6), Transmission rod (7), sealing ring (8), transmission shaft (9), sealing ring (10), bearing (11), flow channel A-I (12), upflow plate (13), sealing ring (14), Downflow plate (15), flow channel B-II (16), ring chamber housing (17), ring inner chamber (18), piston hammer (19), lower housing (20), ring outer chamber (21), Anvil (22), runner (23), sealing ring (24), half ring (25), elastomer (26), octagonal sleeve (27), runner A-Ⅱ (28), runner A-Ⅲ (29), flow channel B-I (30), flow channel A-IV (31), flow channel B-Ⅲ (32), characterized in that: outside the tool, the upper shell (2) and the lower shell ( 20) Connected by threads; the multi-stage turbine stator (5) and the turbine rotor (6) are assembled on the turbine shaft (3) through the flat key (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com