Vibration reduction and reinforcement method for large-size liquid crystal display

A liquid crystal display, large-scale technology, used in instruments, nonlinear optics, optics, etc., can solve the problems of reducing the environmental reliability of the liquid crystal screen, the thickness of the front glass, and the large periodic stress, and improve the display quality and environment. Reliability, reduce failure rate, prolong impact time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

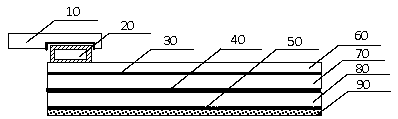

[0031] Such as figure 1 shown.

[0032] A vibration reduction and reinforcement method for a large-size liquid crystal display. The reinforcement structure adopted includes 3 layers of fully bonded optical adhesive layers and 3 optical substrates in front of the screen to form a vibration reduction protection layer. The vibration reduction protection layer is combined with a 17-inch liquid crystal display. The large-size LCD screen assembly is then flexibly connected to the structural front shell 10. Among them, the front of the 17-inch LCD screen 90 is fully bonded to the optical substrate and the optical glue used is silicone gel with a hardness of OO40 and a thickness of 0.2mm. Glue 30, 1.1mm thick PMMA plate 60, hardness OO60, silicone gel 40 with thickness 0.3mm, glass 70 with 1.1mm thickness, UV glue 50 with hardness A15, thickness 0.3mm and glass 80 with 0.8mm thickness, get The equivalent refractive index of the optical sandwich panel is 1.51; the structural front she...

Embodiment 2

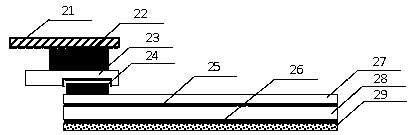

[0034] Such as figure 2 shown.

[0035]A vibration reduction and reinforcement method for a large-size liquid crystal display. The reinforcement structure used includes a vibration-reduction protective layer composed of two layers of fully laminated optical glue and two layers of optical substrates in front of the screen, that is, an optical sandwich panel, and a 25.6-inch liquid crystal display. The screen is compounded to form a large-size LCD screen component, and then it is flexibly connected to the inner and outer front shells of the structure. Among them, the front of the 25.6-inch LCD screen 29 is fully bonded with the optical substrate and the optical glue used is A8 in hardness and thickness 0.4mm silica gel 25, 0.8mm thick PA plate 27, epoxy glue 26 with hardness A20 and 0.3mm thickness, 1.1mm thick glass 28, the equivalent refractive index of the obtained optical sandwich panel is 1.48; The shell 23 is a copper-zinc-aluminum alloy, the inner surface of the front s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com