Soft magnetic ferrite core and method for manufacturing same

A soft magnetic ferrite and manufacturing method technology, applied in the direction of inductance/transformer/magnet manufacturing, manufacturing tools, magnetic core/yoke, etc., can solve the problem of limited hollow cross-section of the skeleton, difficulty in high inductance coils, and affecting the inductance of the magnetic core and other problems, to achieve the effect of low labor intensity, high work efficiency, and guaranteed product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

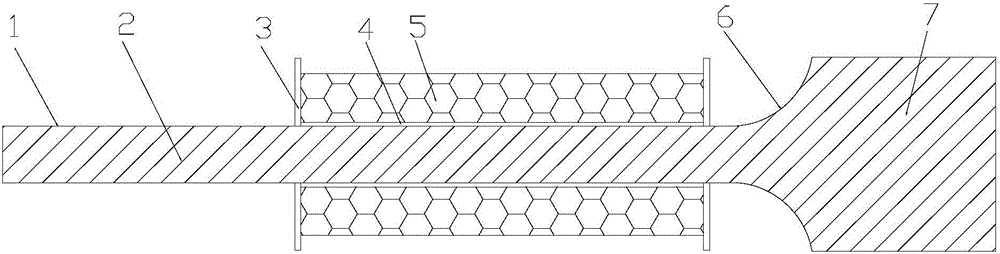

[0021] Such as figure 1 Shown, a kind of soft ferrite magnetic core, comprises skeleton 3, the wire 5 that is wound in the wire groove on skeleton 3, is located at the magnetic core 1 in skeleton 3, and described skeleton 3 is provided with fixing hole 4, described The magnetic core 1 is inserted in the fixing hole 4, and the magnetic core 1 includes a mounting section 2 connected and fixed to the fixing hole 4 on the skeleton 3, an amplifying section 7 arranged at one end of the installing section 2 for improving magnetic flux efficiency, and an amplifying section 7 arranged at the amplifying section 2. The transition section 6 between the section 7 and the installation section 2, the transition section 6 is a regular transition of the divergence curve of the magnetic force line; the installation section 2 matches the shape of the fixing hole 4, and the maximum cross section of the enlarged section 7 is less than or equal to the skeleton 3 The largest profile; the shape of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com