A preparation method for high-strength plastic austenitic stainless steel cap screw forgings for nuclear power

An austenitic stainless steel, high-strength technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problem that it is difficult to meet the high strength, high plasticity, corrosion resistance and high temperature stress relaxation resistance of cap screw forgings at the same time. Achieve the effect of improving solid solution strengthening effect, increasing strength and toughness, and improving high temperature stress relaxation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

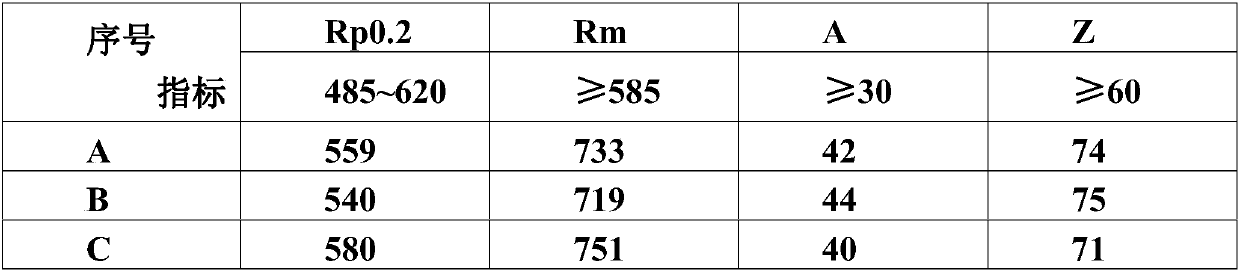

Embodiment 1

[0023] The composition of the base metal electrode for electroslag is controlled at: Ni 12.20~12.60%, Cr 17.50~17.80%, Mo2.50~2.75%, Mn 1.50~1.80%, Si 0.30~0.50%, C 0.025~0.035%, Co≤ 0.05%, N0.04~0.06%, the balance of Fe. The electroslag electrode prepared in this example has the following components: Ni 12.46%, Cr 17.68%, Mo2.71%, Mn 1.76%, Si 0.34%, C 0.032%, Co≤0.016%, N 0.053%, Fe balance . During the electroslag process, the melting current is controlled at 9500-12000A, and the remelting voltage is controlled at 65-80V. In this example, the melting current is 10500A, the melting voltage is 72V, and the electroslag is formed into a Φ500mm electroslag ingot.

[0024] The electroslag steel ingot is heated to 1160°C in the furnace. After the holding time meets the requirements, it is out of the furnace for forging. The billet size of the first firing is 250mm square, and the forging ratio is 3. The second firing is from 250mm square to 86 square. The forging ratio is 8.6, a...

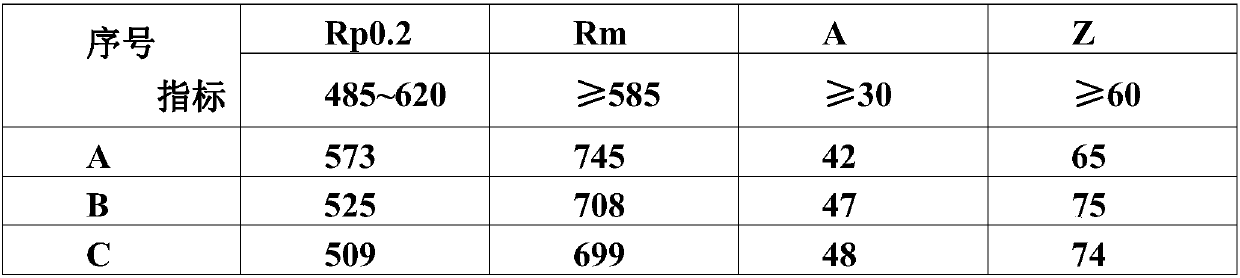

Embodiment 2

[0032] The prepared electrode for electroslag is composed of Ni 12.34%, Cr 17.53%, Mo 2.75%, Mn 1.66%, Si 0.40%, C 0.030%, Co≤0.018%, N 0.059%, and the balance is Fe. The slag smelting current is 10300A, the smelting voltage is 74V, and the electroslag is formed into a Φ500mm electroslag ingot.

[0033] The electroslag steel ingot is heated to 1155°C in the furnace. After the holding time meets the requirements, it is out of the furnace for forging. The blank size of the first firing is 250mm square, and the forging ratio is 3. The second firing is from 250mm square to 86 square. The forging ratio is 8.6, and the total forging ratio is greater than 10.

[0034] After the billet forging is completed, the billet is subjected to solution treatment at 1060°C for 4 hours and water-cooled to room temperature, and then the billet is machined. The size of the billet after machining reaches a square size of 73 mm.

[0035] After the machining is completed, the blank is subjected to cold...

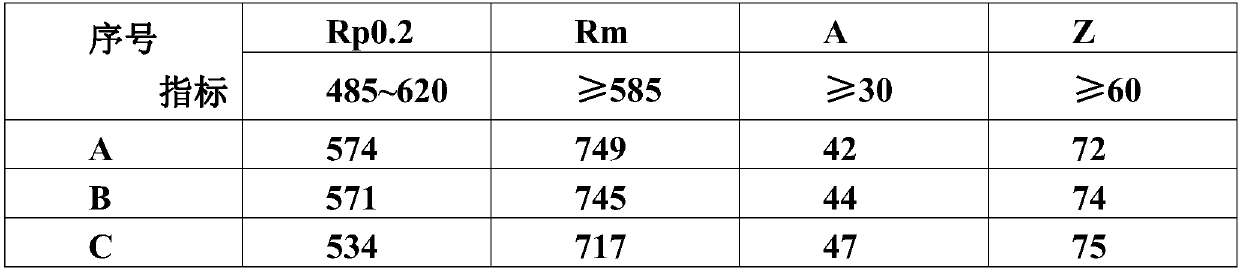

Embodiment 3

[0041] The prepared electrode for electroslag is composed of Ni 12.53%, Cr 17.52%, Mo 2.60%, Mn 1.69%, Si 0.44%, C 0.029%, Co≤0.020%, N 0.058%, and the balance is Fe. The slag smelting current is 11200A, the smelting voltage is 75V, and the electroslag is formed into a Φ500mm electroslag ingot.

[0042] The electroslag steel ingot is heated to 1158°C in the furnace. After the holding time meets the requirements, it is taken out of the furnace for forging. The blank size of the first firing is 250mm square, and the forging ratio is 3. The second firing is from 250mm square to 86 square. The forging ratio is 8.6, and the total forging ratio is greater than 10.

[0043] After the billet forging is completed, the billet is subjected to solution treatment at 1070°C for 4 hours and water-cooled to room temperature, and then the billet is machined. The size of the billet after machining reaches a square size of 74mm.

[0044] After the machining is completed, the blank is subjected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com