Solar tracking interconnection robot

A solar tracking and robot technology, applied in the field of solar tracking interconnected robots, can solve the problems of large amount of motor sensors and electronic controls, parts that cannot be lightweighted, and cannot be linked with each other, so as to improve the comprehensive efficiency of light and heat, reduce consumption and cost, The effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments according to the accompanying drawings.

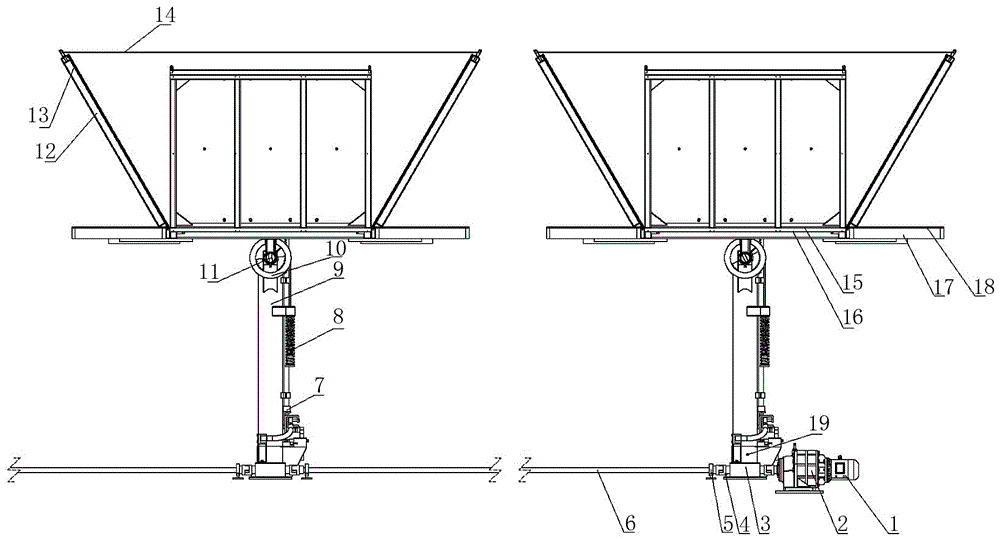

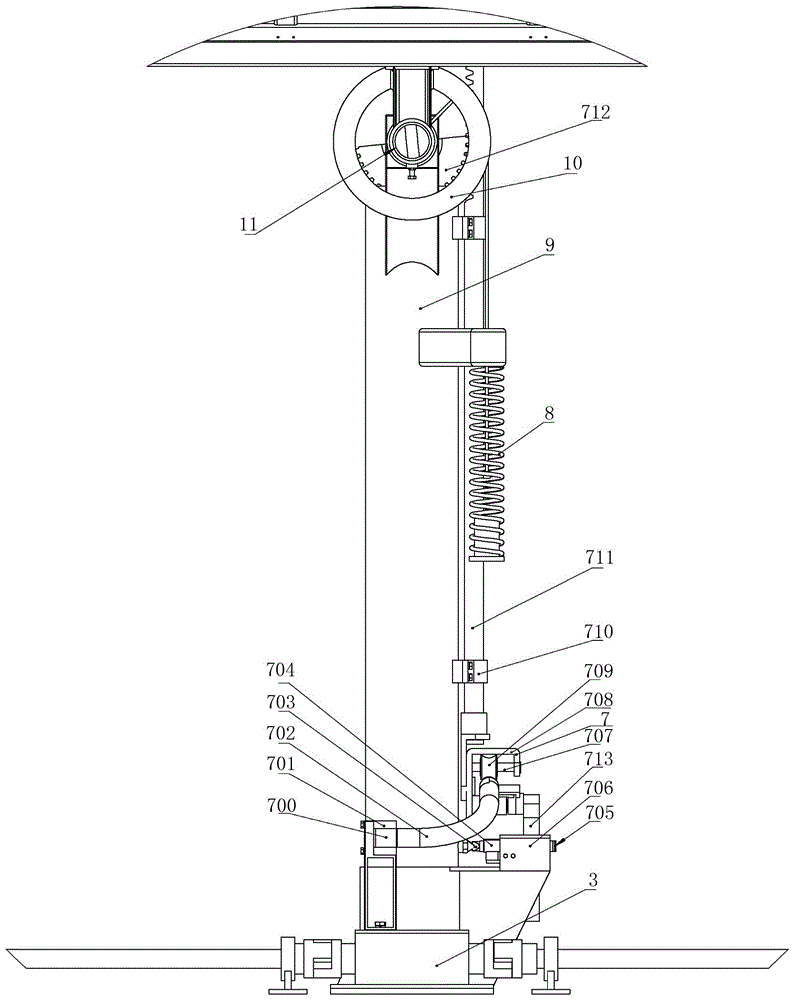

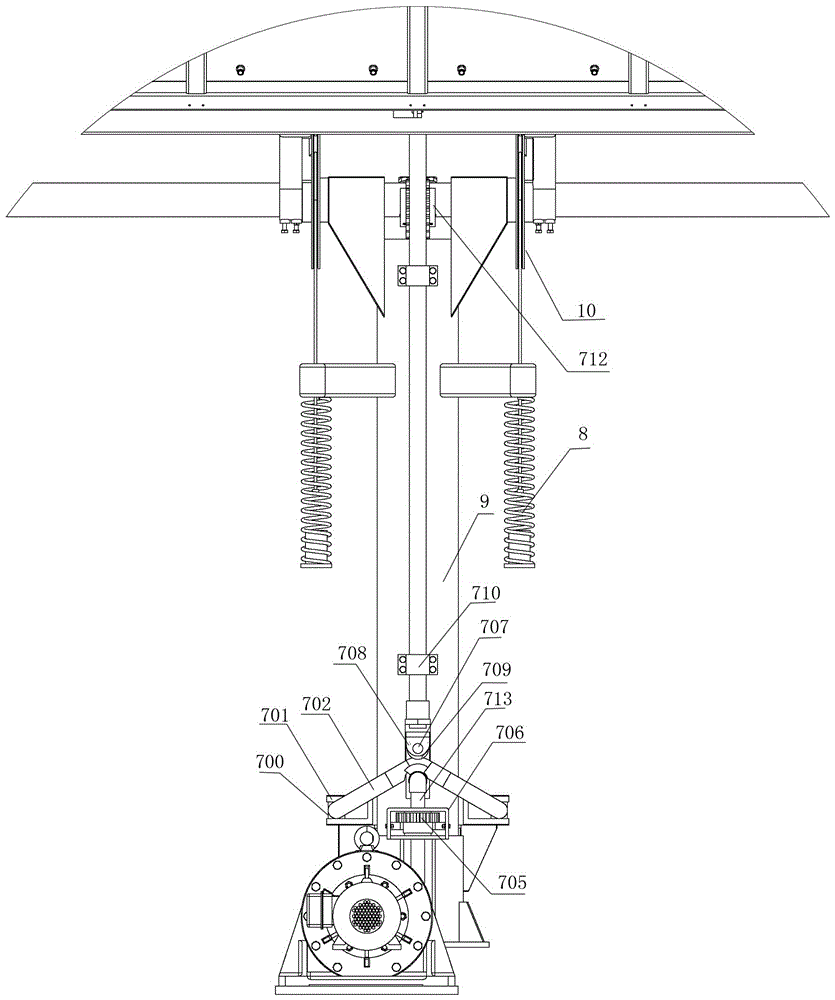

[0014] Such as figure 1 , 2 , 3, the solar tracking interconnected robot includes a drive mechanism, an azimuth tracking transmission mechanism, and an elevation angle tracking transmission mechanism 7. 6. The bearing seat 5 is connected with several azimuth tracking transmission mechanisms, the driving mechanism includes a motor 1 (preferably a frequency conversion motor), a reducer 2 (preferably a multi-stage harmonic motor); the azimuth tracking transmission mechanism includes a worm gear The reducer 3, the main column tube seat 19, the main column 9, the support main shaft 11 and the main support 16 (on which the photovoltaic photothermal assembly 15 is arranged) arranged on the main column; the height angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com