Rice stick processing equipment and rice stick processing method

A processing equipment and technology for rice sticks, which are applied in the field of rice stick processing equipment and rice stick processing, can solve the problems of cumbersome rice stick making process, time-consuming and laborious mold making and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

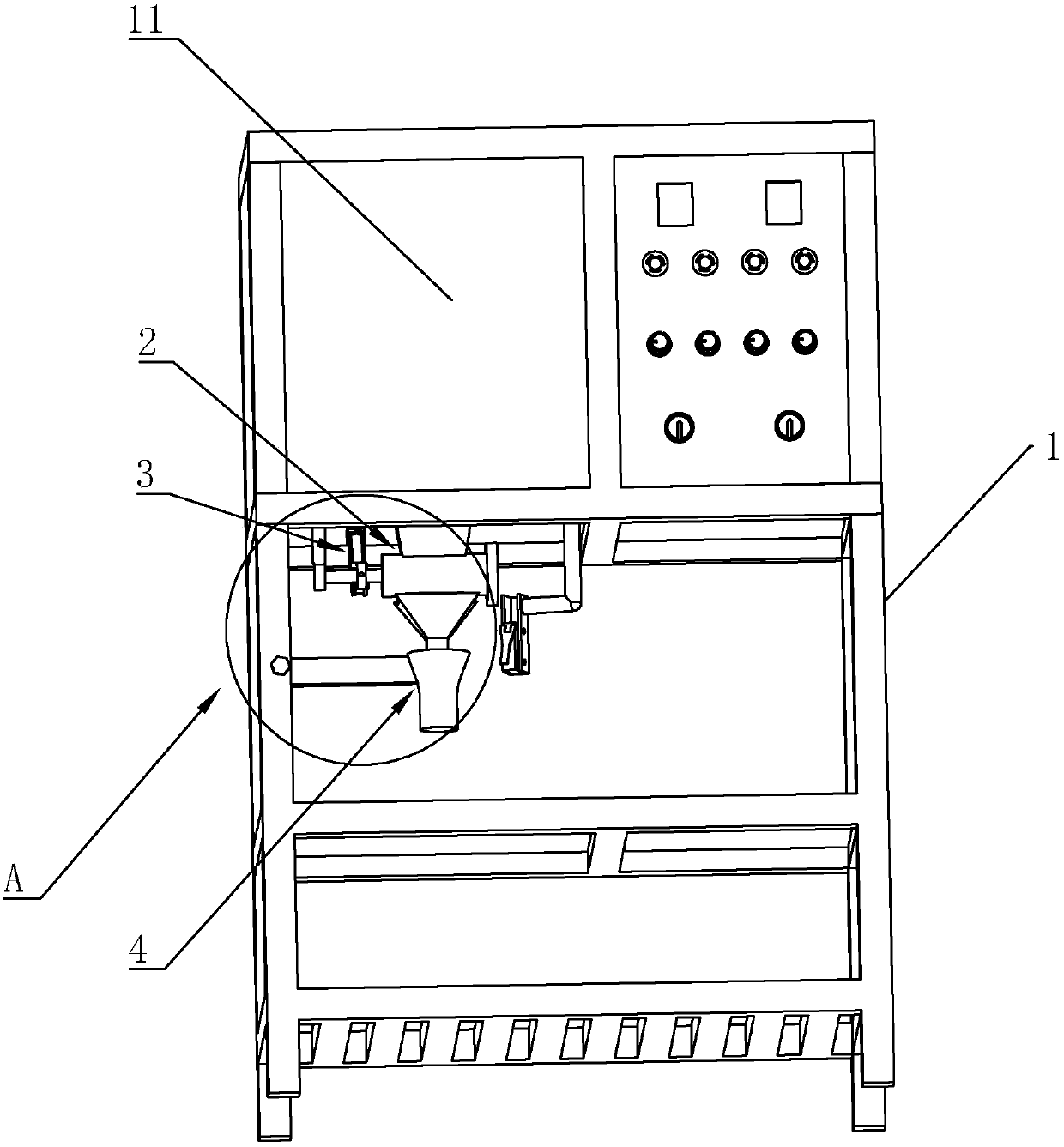

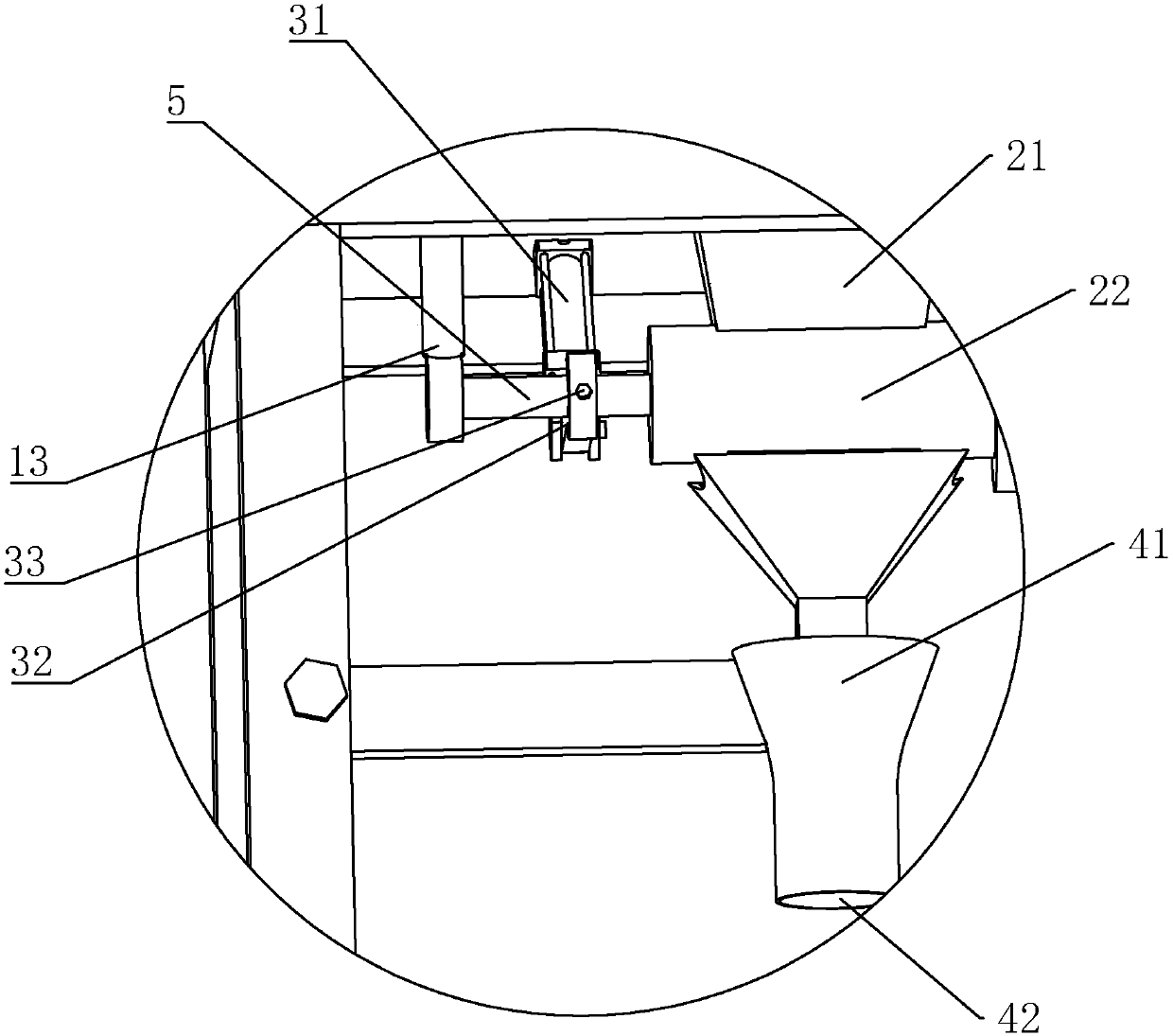

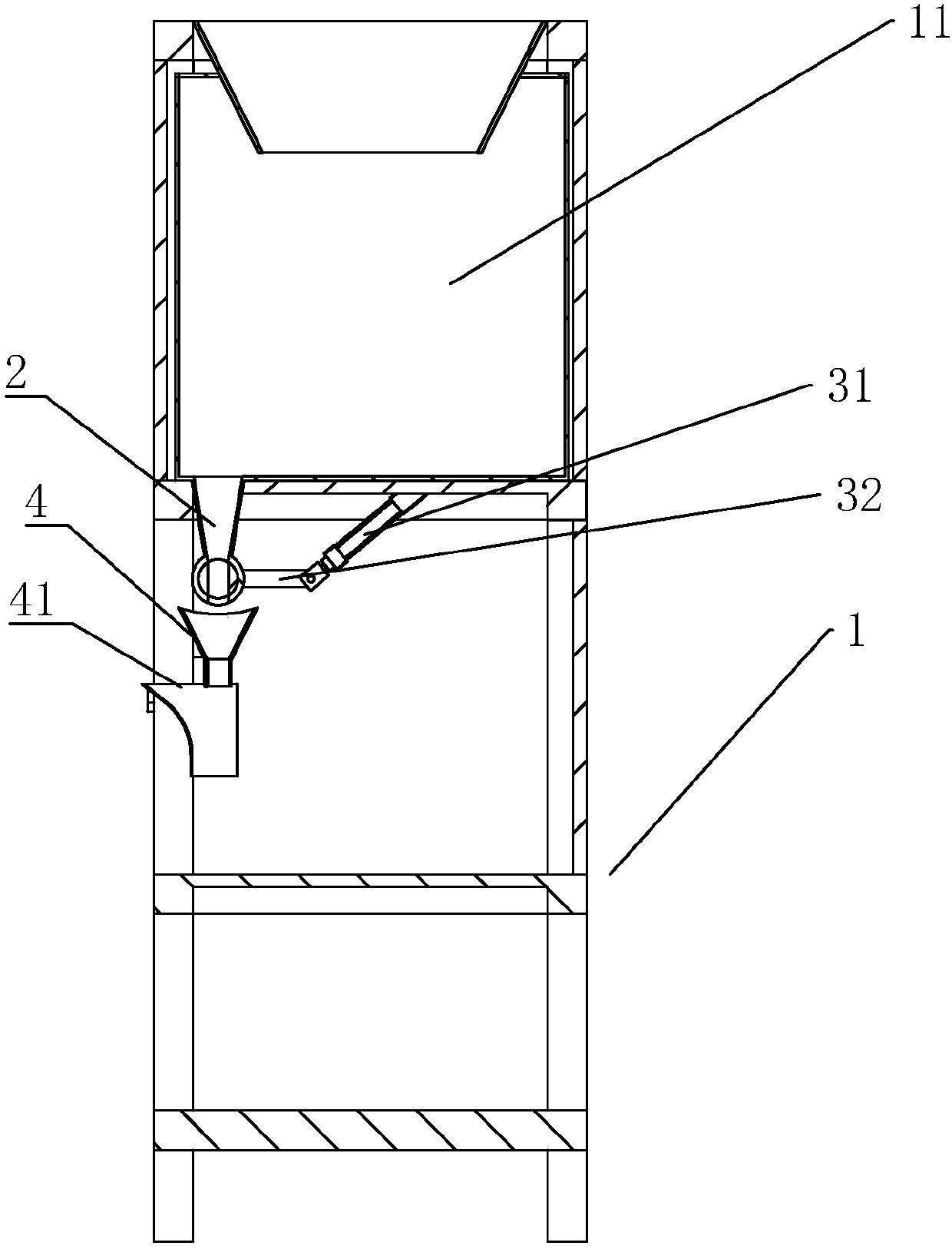

[0055] Embodiment 1: a kind of rice stick processing equipment, such as figure 1 As shown, the frame 1 is provided with a material storage box 11, the top of the material storage box 11 is provided with a feeding port, and the bottom is connected with a discharge device; The connected discharge hopper 2, the discharge rod 5 which is installed in the discharge hopper 2 and connected to the discharge hopper 2 in rotation, and the drive mechanism 3 which is sleeved on the discharge rod 5 for driving the reciprocating rotation of the discharge rod 5 ; The discharge hopper 2 includes a feed portion 21 communicated with the material storage box 11, a discharge portion 22 communicated with the feed portion 21 and being cylindrically arranged, and a discharge port 23 provided at the bottom of the discharge portion 22, the feed portion 21 and the discharge part 22 are formed with a port 24; the discharge rod 5 is penetrated in the discharge part 22, the discharge rod 5 includes a rod b...

Embodiment 2

[0065] Embodiment two: a kind of rice stick processing equipment, such as figure 1 As shown, the frame 1 is provided with a material storage box 11 and a soup storage tank 12, the bottom of the material storage box 11 is connected with a discharge device, and the soup storage tank 12 is connected with an outlet pipe 64; The discharge hopper 2 at the bottom of the box 11 and communicated with the storage tank 11, the discharge rod 5 that is installed in the discharge hopper 2 and is rotatably connected with the discharge hopper 2, and the discharge rod 5 that is sleeved on the discharge rod 5 is used to drive the discharge rod 5. The drive mechanism 3 for the reciprocating rotation of the material rod 5; the discharge hopper 2 includes a feed part 21 communicated with the storage box 11, a discharge part 22 communicated with the feed part 21 and arranged in a cylindrical shape, and set at the bottom of the discharge part 22 The discharge port 23, the opening 24 is formed betwee...

Embodiment 3

[0071] Embodiment three: a kind of rice stick processing method, comprises the following steps:

[0072] 1. Raw material addition: add cleaned rice in the material storage box 11, and add soup stock prepared from seasonings such as water, oil, soy sauce, and salt in the soup stock tank 12; the water, oil, and soy sauce in the soup stock Seasonings such as rice and salt are all configured according to a certain ratio, and of course different forms of seasonings can be added to make the rice sticks into different tastes.

[0073] 2. Mixed bagging: open the special packaging bag at the bottom of the discharge port 42, start the control switch, control the drive mechanism 3 and the water outlet device 6 to work; the drive mechanism 3 drives the discharge rod 5 to rotate, so that the rice is discharged from the discharge port 23 Enter in the mixing hopper 4; Water outlet device 6 extracts quantitative soup stock from soup storage tank 12, and enters in the mixing hopper 4 from outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com