High-speed breaking machine special for building ceramic raw material breaking

A technology of raw materials and crushers, which is applied in the field of dry powder milling production technology and equipment in the building ceramics industry, can solve the problems of not meeting the needs of factories, the reduction of crushing capacity, and small output, so as to reduce the difficulty of work, improve the crushing effect, and increase output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

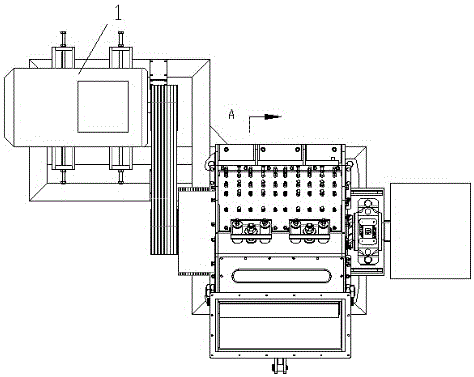

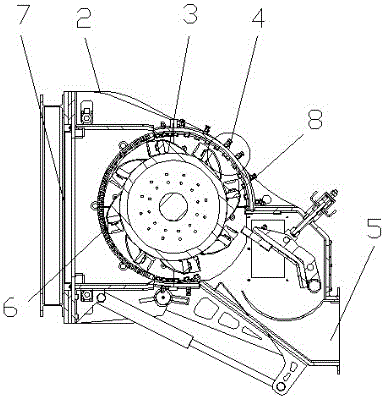

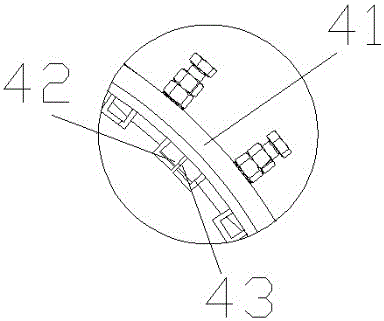

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a special high-speed crusher for crushing building ceramic raw materials includes an upper casing 4, a lower casing 2, a feed port 5, a discharge port 7, a driving device, a rotating shaft assembly 3 and a crushing device. The device is connected with the rotating shaft assembly 3 through a pulley, and the driving device is fixedly arranged on the outer end of the casing. The casing includes an upper casing 4 and a lower casing 2, and the upper casing 4 and the lower casing 2 are fixedly connected by bolts , the rotating shaft assembly 3 is fixedly arranged at the inner end of the casing, the crushing device is fixedly arranged on the outer su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com