Emulsified asphalt special for spraying rubber asphalt paint and preparation method of emulsified asphalt

A technology for emulsified asphalt and asphalt emulsifier, used in asphalt coatings, coatings, etc., can solve the problems of poor compatibility of polymer emulsions, poor low temperature resistance, and insufficient demulsification time, and achieve performance indicators. Superior, long working time, excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

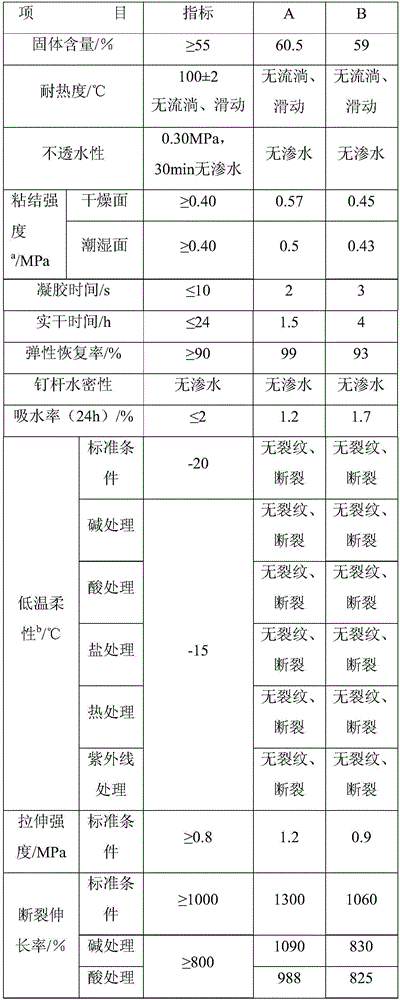

Embodiment 1

[0050] Add 100 parts by weight of 70# petroleum asphalt in the emulsified asphalt equipment, and keep it at 132 ° C; add 63 parts by weight of water, add 2.5 parts by weight of composite anionic asphalt emulsifier, add 1 part by weight of pH agent (sodium hydroxide ), adding 0.1 parts by weight of the stabilizer, the temperature is 55 ° C, and high-speed shear stirring is carried out to obtain an anionic emulsified asphalt with a solid content of 60.5%.

[0051] In the above-mentioned embodiment, the composite anionic asphalt emulsifier is obtained by compounding secondary alkyl sodium sulfonate, sodium lauryl polyoxyethylene ether carboxylate and sodium lauryl sulfate, and the mass percentage of each component is 50%, 5% and 45%.

[0052] In the above examples, the stabilizer is a compound of sodium hydroxymethylcellulose and ethylene glycol, and the mass ratio of the two is 2:1.

[0053] The storage stability test of the emulsified asphalt prepared by the present embodiment...

Embodiment 2

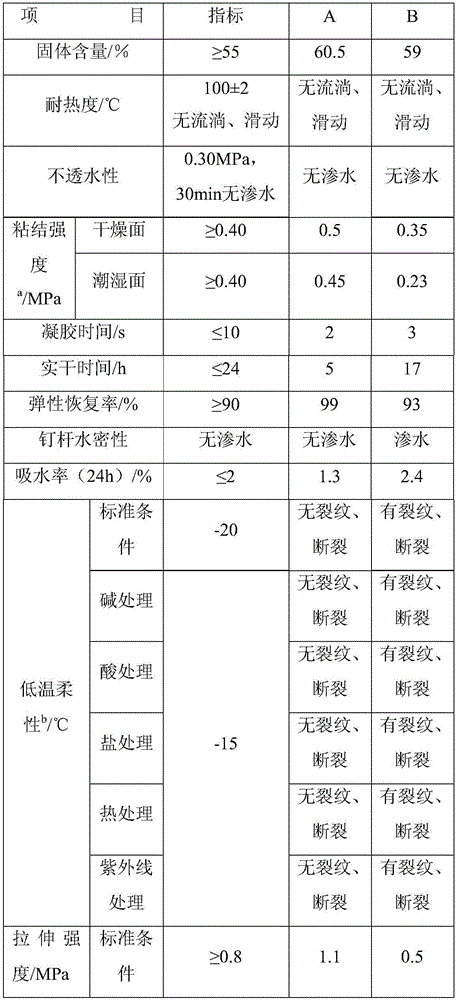

[0065] Add 85 parts by weight of 70# petroleum asphalt in the emulsified asphalt equipment, and keep it at 132 ° C; add 63 parts by weight of water, add 2.5 parts by weight of composite anionic asphalt emulsifier, add 1 part by weight of pH agent (sodium hydroxide ), adding 0.1 parts by weight of the stabilizer, the temperature is 55 ° C, and high-speed shearing and stirring are carried out to obtain an anionic emulsified asphalt with a solid content of 56%.

[0066] In the above-mentioned examples, the composite anionic asphalt emulsifier is compounded from secondary alkyl sodium sulfonate, sodium lauryl polyoxyethylene ether carboxylate and sodium lauryl sulfate, and the mass percentage of each component is 50%, 5% and 45%.

[0067] In the above examples, the stabilizer is a compound of sodium hydroxymethylcellulose and ethylene glycol, and the mass ratio of the two is 2:1.

[0068] The storage stability test of the emulsified asphalt prepared by the present embodiment:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com