A kind of preparation method of conductive polyurethane light conveyor belt

A light conveyor belt and polyurethane technology, applied in polyurea/polyurethane coatings, conveyors, conductive coatings, etc., can solve the problems of material processing performance, reduction of material tensile strength and elongation at break, and large waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Carboxymethylcellulose (CMC) is dissolved in water, and the concentration of the aqueous solution is 10%.

[0027] (2) Disperse the carbon nanotubes in the CMC aqueous solution at a concentration of 10%, and vibrate ultrasonically for 30 minutes.

[0028] (3) Add the CMC / carbon nanotube mixed liquid to the water-based polyurethane to configure the water-based polyurethane conductive liquid, and the ratio of the mixed liquid to the water-based polyurethane is 1:10.

[0029] (4) The polyester fabric is dried and shaped in a far-infrared heating oven at a drying temperature of 80°C.

[0030] (5) Use the calendering method to compound the TPU on the front and back of the fabric to form a composite layer of the conveyor belt; during the compounding process, the calendering temperature is 180°C, the compounding pressure is 10Pa, and the fabric surface temperature is always maintained at 150°C. The thickness of the composite layer is 0.3mm.

[0031] (6) Coating polyureth...

Embodiment 2

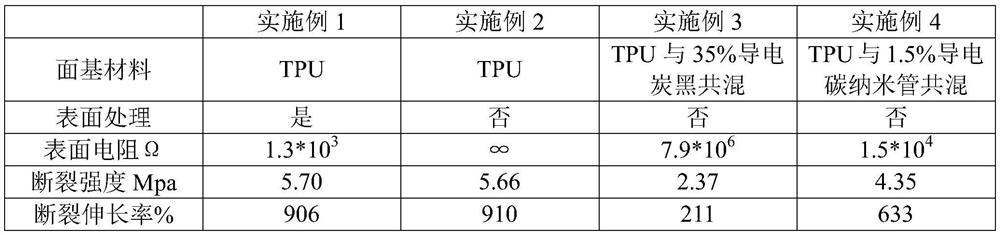

[0033] Use the calendering method to compound the TPU on the front and back of the fabric respectively to form a composite layer of the conveyor belt; during the compounding process, the calendering temperature is 180°C, the compounding pressure is 10Pa, and the fabric surface temperature is always kept at 150°C. Thickness 0.3mm. The specific test results are shown in Table 1.

Embodiment 3

[0035] (1) Fully mix 35% conductive carbon black with 65% TPU;

[0036] (2) Use the calendering method to compound the mixture obtained in (1) on the front and back sides of the fabric respectively to form a conveyor belt composite layer; It is always kept at 150°C, and the thickness of the composite layer is 0.3mm. The specific test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com