Wood-plastic composite material for packaging box and packaging box preparation method

A wood-plastic composite material, packaging box technology, applied in packaging, wrapping paper, biological packaging and other directions, can solve problems such as surface quality problems of packaging boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

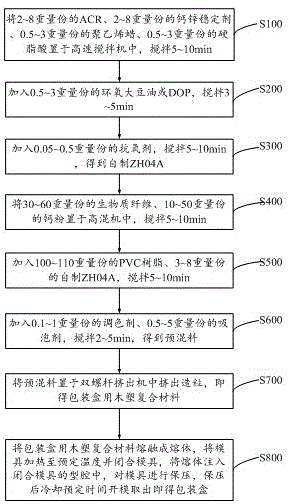

[0048] see figure 1 , the packing box preparation method of one embodiment, comprise the following steps:

[0049] S100. Put 2-8 parts by weight of ACR, 2-8 parts by weight of calcium zinc stabilizer, 0.5-3 parts by weight of polyethylene wax, and 0.5-3 parts by weight of stearic acid in a high-speed mixer, and stir for 5~ 10min.

[0050] Among them, the rotating speed of the high-speed mixer is 150~180rpm, first stir at a low speed to make the four kinds of raw materials mix evenly.

[0051] S200, adding 0.5-3 parts by weight of epoxidized soybean oil or DOP, and stirring for 3-5 minutes.

[0052] Continue to keep the speed of the high-speed mixer at 150~180rpm, and add epoxy soybean oil or DOP to disperse the materials.

[0053] S300, adding 0.05-0.5 parts by weight of an antioxidant, stirring for 5-10 minutes to obtain self-made ZH04A.

[0054] Wherein, the antioxidant is 1010 antioxidant. Adjust the speed of the high-speed mixer to 450~500rpm, add 1010 antioxidant, st...

Embodiment 1

[0074] A method for preparing a packaging box, comprising the following steps:

[0075] 1. Preparation of self-made ZH04A

[0076] The ACR of 3 parts by weight, the calcium-zinc stabilizer of 3 parts by weight, the polyethylene wax of 0.8 parts by weight, and the stearic acid of 0.8 parts by weight are placed in a high-speed mixer, and stirred at a speed of 150 rpm for 5 min;

[0077] Add the epoxidized soybean oil of 0.8 weight part, stir 3min;

[0078] After adjusting the speed of the high-speed mixer to 450rpm, add 0.05 parts by weight of 1010 antioxidant, and stir for 5 minutes to obtain self-made ZH04A.

[0079] 2. Mixing

[0080] The bamboo powder of 45 parts by weight, the calcium carbonate of 5 parts by weight are placed in the high mixer, after stirring at a low speed of 450rpm for 5min, the rotating speed of the high mixer is adjusted to 1500rpm until the temperature of the high mixer rises to 70°C;

[0081] After adjusting the speed of the high mixer to 450rpm, a...

Embodiment 2

[0092] A method for preparing a packaging box, comprising the following steps:

[0093] 1. Preparation of self-made ZH04A

[0094] The ACR of 5 parts by weight, the calcium-zinc stabilizer of 5 parts by weight, the polyethylene wax of 1 part by weight, the stearic acid of 1 part by weight are placed in a high-speed mixer, and stirred at a rotating speed of 180rpm for 5min;

[0095] Add the epoxidized soybean oil of 1 weight part, stir 3min;

[0096] After adjusting the speed of the high-speed mixer to 450rpm, add 0.08 parts by weight of 1010 antioxidant, and stir for 5 minutes to obtain self-made ZH04A.

[0097] 2. Mixing

[0098] The bamboo powder of 50 parts by weight, the calcium carbonate of 15 parts by weight are placed in the high mixer, after stirring at a low speed of 450rpm for 5min, the rotating speed of the high mixer is adjusted to 1500rpm until the temperature of the high mixer rises to 70°C;

[0099] After adjusting the speed of the high mixer to 450rpm, add 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com