Preparation method for antiallergic breathable easy-to-tear medical adhesive tape base cloth and production device adopting preparation method

A breathable, anti-allergic technology, applied in the field of medical supplies, can solve the problems of cumbersome preparation methods of medical tape base fabrics, poor air permeability of medical tape base fabrics, unreasonable design of production equipment, etc., to maintain natural tearability, production The structure of the device is simple and practical, and the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

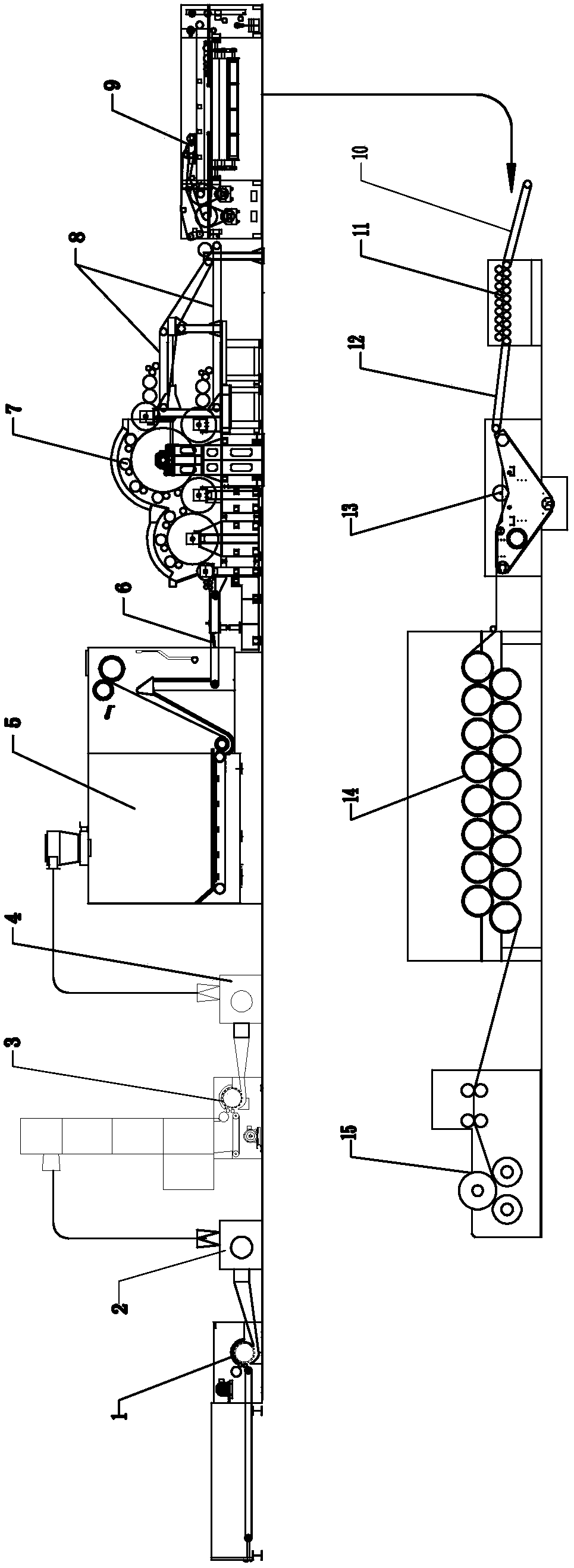

[0032] A-1. The production device of the anti-allergic breathable type easy-to-tear medical tape base cloth in this embodiment

[0033] as attached figure 1 As shown, it includes: opening machine 1, conveying mechanism 2, fine opening machine 3, conveying mechanism after opening 4, feeding quantitative cotton feeder 5, fiber conveying mechanism 6, fiber carding machine 7, carding conveying mechanism 8. Width control lapper 9, conveyor belt 10, drafting machine 11 that changes the ratio of fiber vertical and horizontal strength, fiber mesh conveying mechanism 12, double-net dipping machine 13, dryer 14, winding machine 15, start The rear part of the loosening machine 1 is a two-stage mixed opening machine composed of a conveying mechanism 2 connected to a fine opening machine 3. The fine opening machine 3 is connected to a quantitative feeder 5 by a conveying mechanism 4 after opening. The cotton device 5 is connected to the fiber carding machine 7 through the fiber conveying ...

Embodiment 2

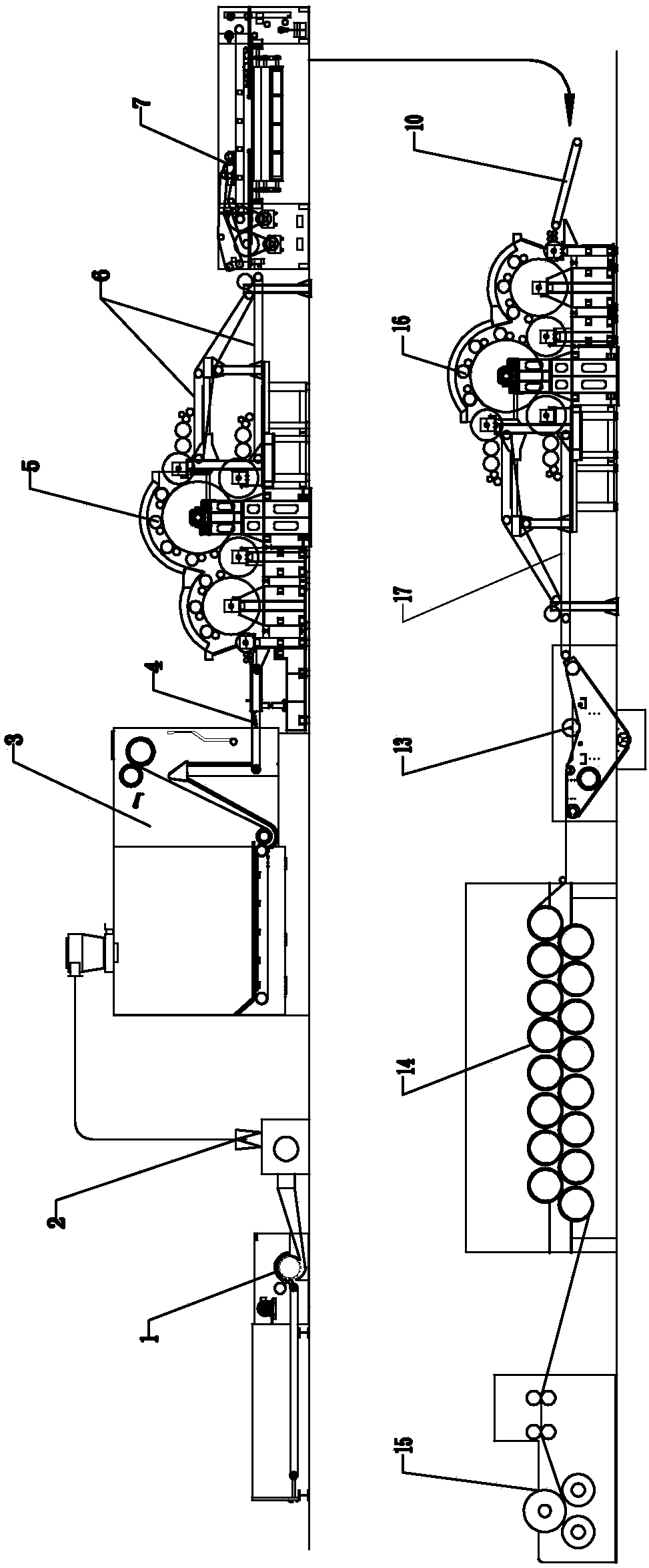

[0043] A-2. The production device of the anti-allergic breathable type easy-to-tear medical tape base cloth of this embodiment

[0044] as attached figure 2 As shown, it includes: opening machine 1, conveying mechanism 2, material quantitative feeder 5, fiber conveying mechanism 6, fiber carding machine 7, carding conveying mechanism 8, width control lapper 9, conveyor belt 10 , fiber combing machine 16, combing conveying mechanism 17, double-wire dipping machine 13, drying machine 14, winding machine 15, the rear part of the opening machine 1 is connected with the feeding quantitative cotton device 5 by the conveying mechanism 2, for The material quantitative feeder 5 is connected to the fiber carding machine 7 through the fiber conveying mechanism 6, and the fiber carding machine 7 is connected to the control width lapper 9 by the fiber conveying mechanism 8. Carding machine 16, the rear of fiber combing machine 16 is connected to double-wire dipping machine 13 by combing ...

Embodiment 3

[0054] A-3. The production device of the anti-allergic breathable type easy-to-tear medical tape base cloth of this embodiment

[0055] as attached figure 1 As shown, it includes: opening machine 1, conveying mechanism 2, fine opening machine 3, conveying mechanism after opening 4, feeding quantitative cotton feeder 5, fiber conveying mechanism 6, fiber carding machine 7, carding conveying mechanism 8. Width control lapper 9, conveyor belt 10, drafting machine 11 that changes the ratio of fiber vertical and horizontal strength, fiber mesh conveying mechanism 12, double-net dipping machine 13, dryer 14, winding machine 15, start The rear part of the loosening machine 1 is a two-stage mixed opening machine composed of a conveying mechanism 2 connected to a fine opening machine 3. The fine opening machine 3 is connected to a quantitative feeder 5 by a conveying mechanism 4 after opening. The cotton device 5 is connected to the fiber carding machine 7 through the fiber conveying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com