Integrated assembly type residential system and construction method thereof

A prefabricated and integrated wall technology, which is applied to building components, walls, buildings, etc., can solve the problems of many assembly processes, heavy decoration workload, and limited application range, and achieve obvious effects, fast construction speed, and wet operation. good environment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

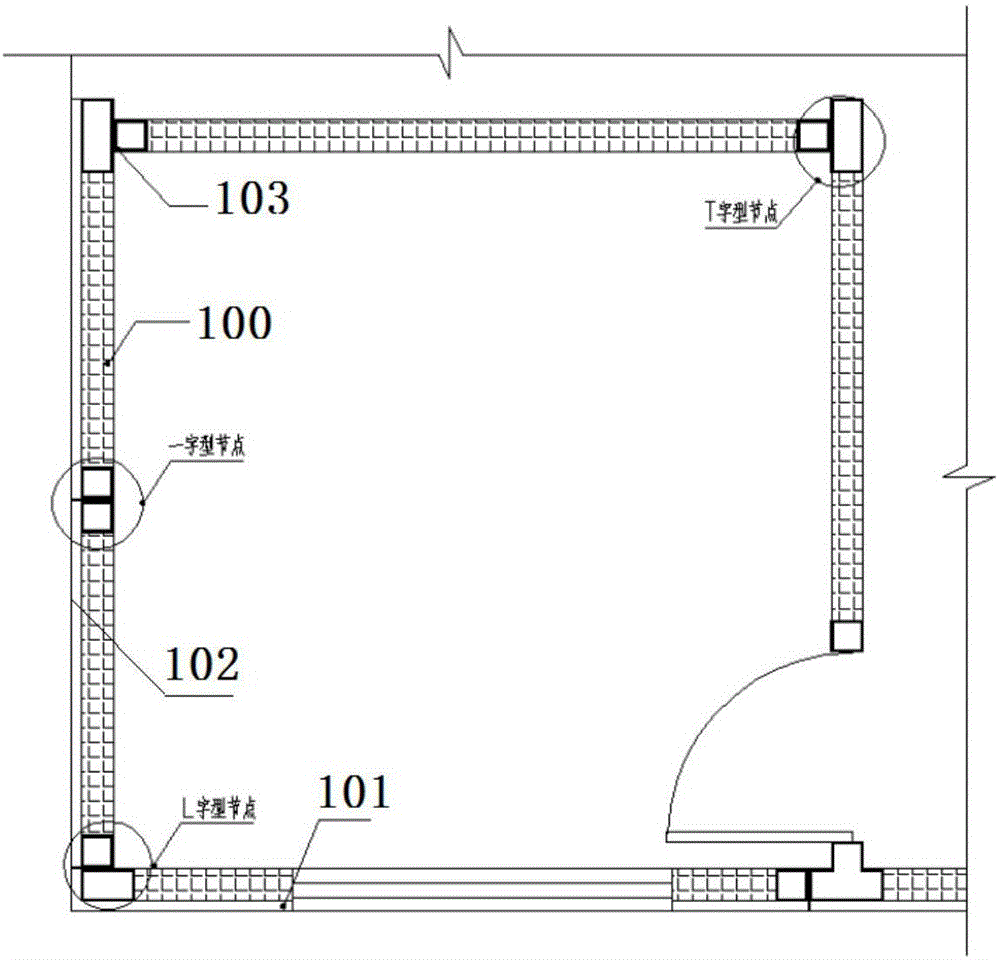

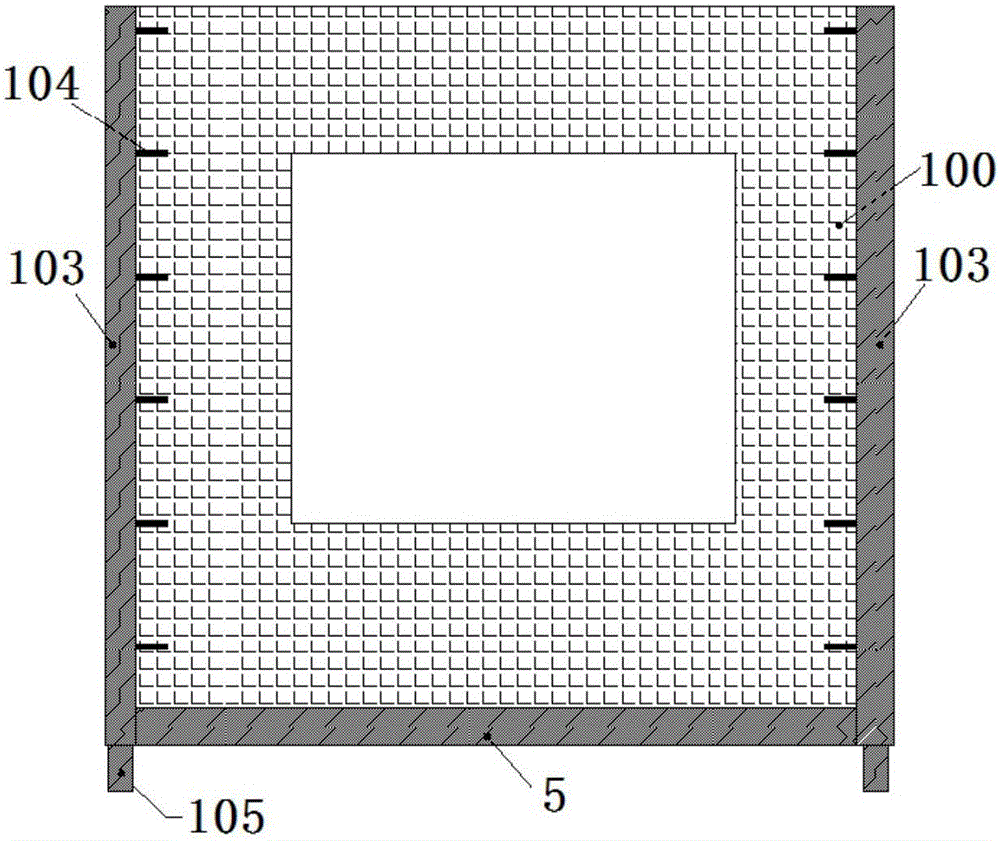

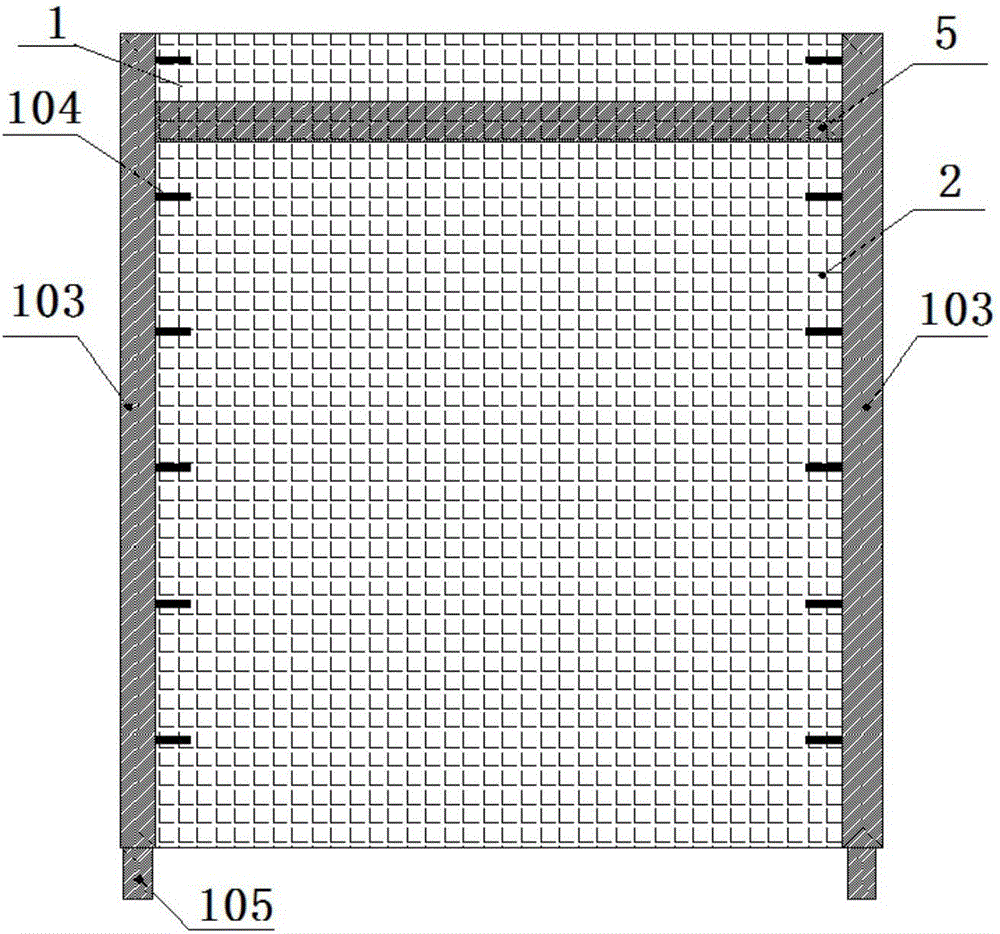

[0052] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments. It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict. For the convenience of description, the words "up", "down", "left" and "right" appear in the following text, which only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

[0053] The end column 103 of the U-shaped steel skeleton or the inverted U-shaped steel skeleton with the hollow section steel, the beam with the H-section steel 5 as the skeleton, and the inner filling wall are prefabricated by lightweight concrete, the thermal insulation layer 101 is extruded board, and the decorative layer 102 is imitation wood Concrete, the floor slab 10 is a laminated slab to illustrate the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com