Pendulum type constant liquid level intelligent pumping unit and constant liquid level oil production method of the pumping unit

A technology of constant liquid level and pumping unit, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., which can solve the problem of inability to directly display the power map, unstable position of the dynamic liquid level, and difficulty in adjusting the stroke order, etc. problems, to achieve the effect of automatic parameter adjustment to save, reduce labor time, and facilitate stroke adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of pumping unit constant liquid surface oil recovery method of the present invention, realizes through following steps:

[0027] a. Determine the fluid level;

[0028] b. Collect the uplink and downlink active power of the motor;

[0029] c. Calculate the average uplink and downlink power;

[0030] d. Adjust stroke times: when the uplink power is greater than the average power of uplink and downlink, the dynamic liquid level will decrease and the stroke times will be reduced;

[0031] e. Constant liquid level oil recovery: adjust the stroke times of step d within the cycle time through the intelligent control device to achieve power balance and constant liquid level oil recovery.

Embodiment 2

[0033] A kind of pumping unit constant liquid surface oil production method of the present invention, realizes through following steps, as figure 1 Shown:

[0034] a. Determine the fluid level;

[0035] b. Collect the uplink and downlink active power of the motor;

[0036] c. Calculate the average uplink and downlink power;

[0037] d. Adjust stroke times: when the uplink power is greater than the average power of uplink and downlink, the dynamic liquid level will decrease and the stroke times will be reduced;

[0038] e. Constant liquid level oil recovery: adjust the stroke times of step d within the cycle time through the intelligent control device to achieve power balance and constant liquid level oil recovery.

[0039] The determination of the position of the dynamic fluid surface described in step a is realized by the following method: obtain the work W of the sucker rod weight 杆 , the work done by the weight of the oil column W 油 , the work done by the weight of the...

Embodiment 3

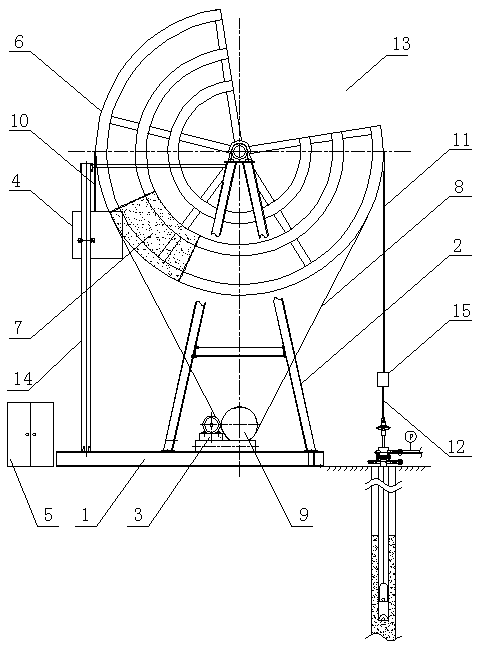

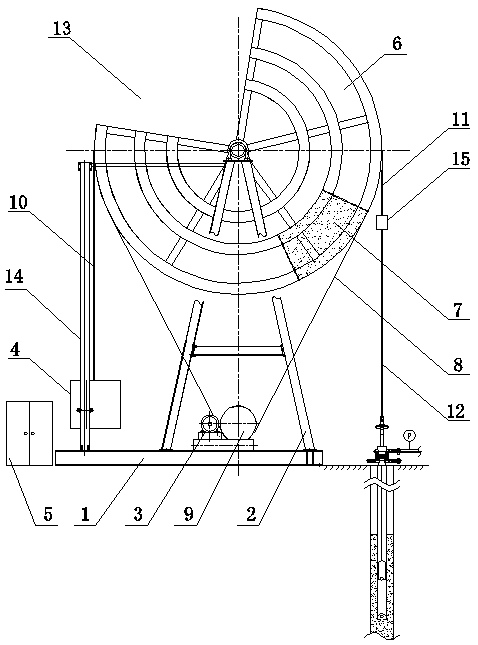

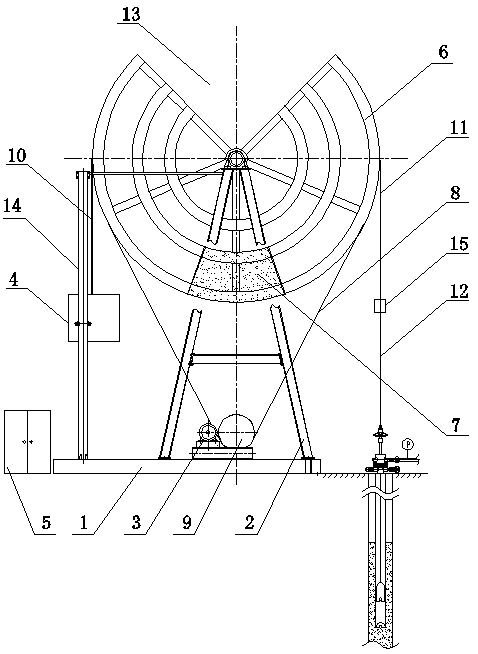

[0042] Pendulum type constant liquid level intelligent pumping unit of the present invention, as figure 1 As shown, it is composed of a base 1, a bracket 2, a motor 3, a counterweight 4 and an electrical control system 5. The bottom of the bracket 2 is fixed to the base 1, and a swing wheel 6 is installed on the top, and a pendulum is arranged at the bottom of the swing wheel 6. The counterweight 7 and the outer periphery of the oscillating wheel 6 are provided with a driving rope 8 and are connected in transmission with the driving wheel 9 fixed on the base 1, and the arc on one side of the top of the oscillating wheel 6 is fixedly connected with a counterweight lanyard 10. A sucker rod hanging rope 11 is fixedly connected to the arc on the other side, the bottom end of the counterweight hanging rope 10 is connected to the counterweight 4, and the bottom end of the sucking rod hanging rope 11 is connected to the sucker rod 12. The drive wheel 9 is connected to the motor 3 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com