Temperature difference energy driven ocean section movement system

An ocean profile and motion system technology, applied in ocean energy power generation, machines/engines, fluid pressure actuation devices, etc., can solve problems such as reduced equipment reliability, excessive energy consumption, equipment failures, etc., to improve life and reliability. Sex, improve the number of exercise, the effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

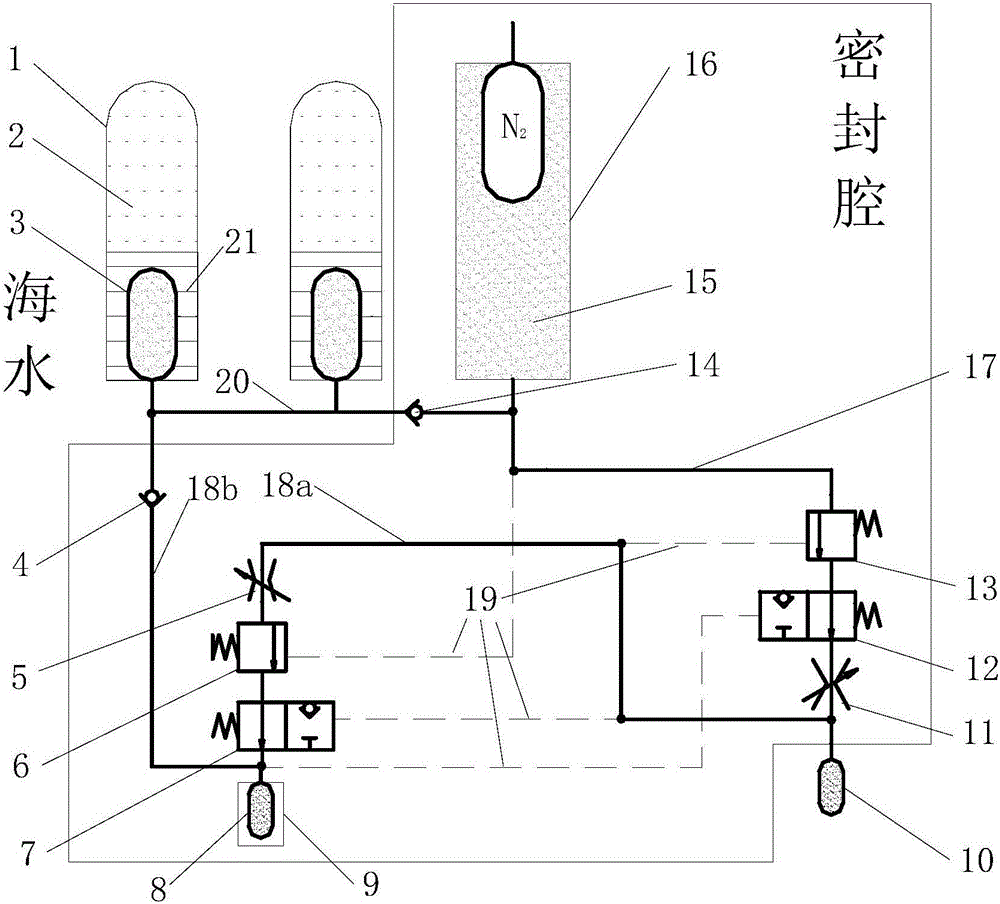

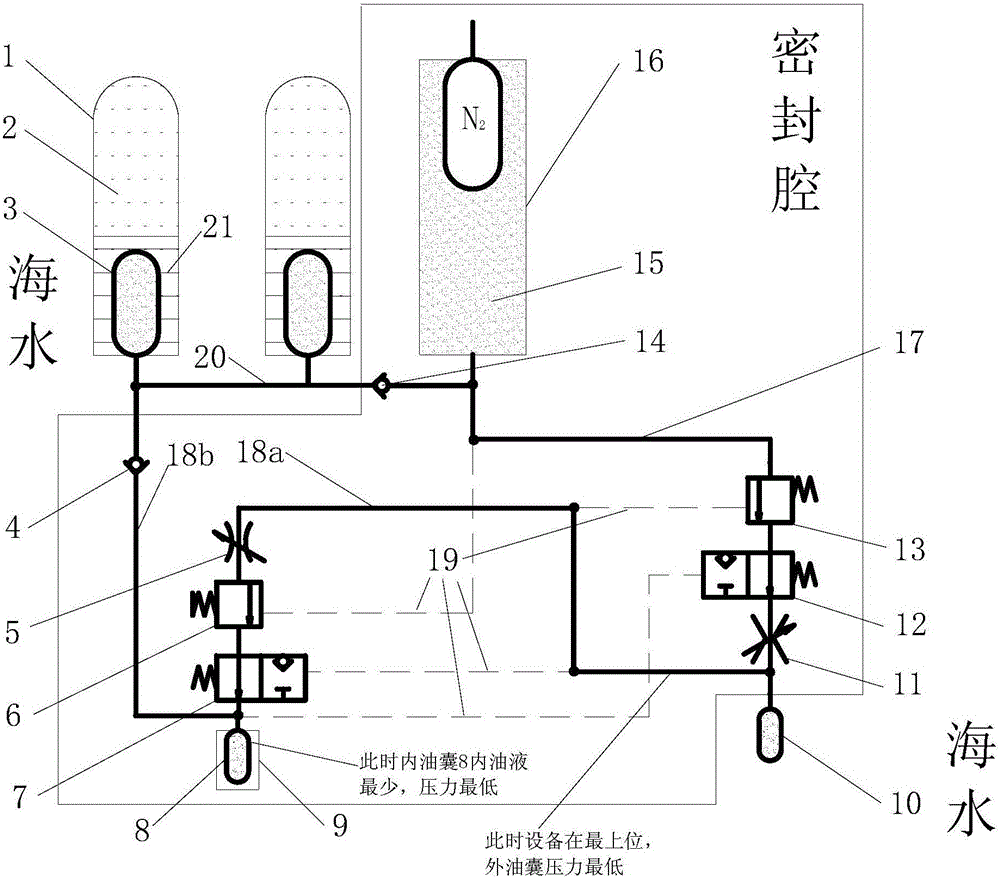

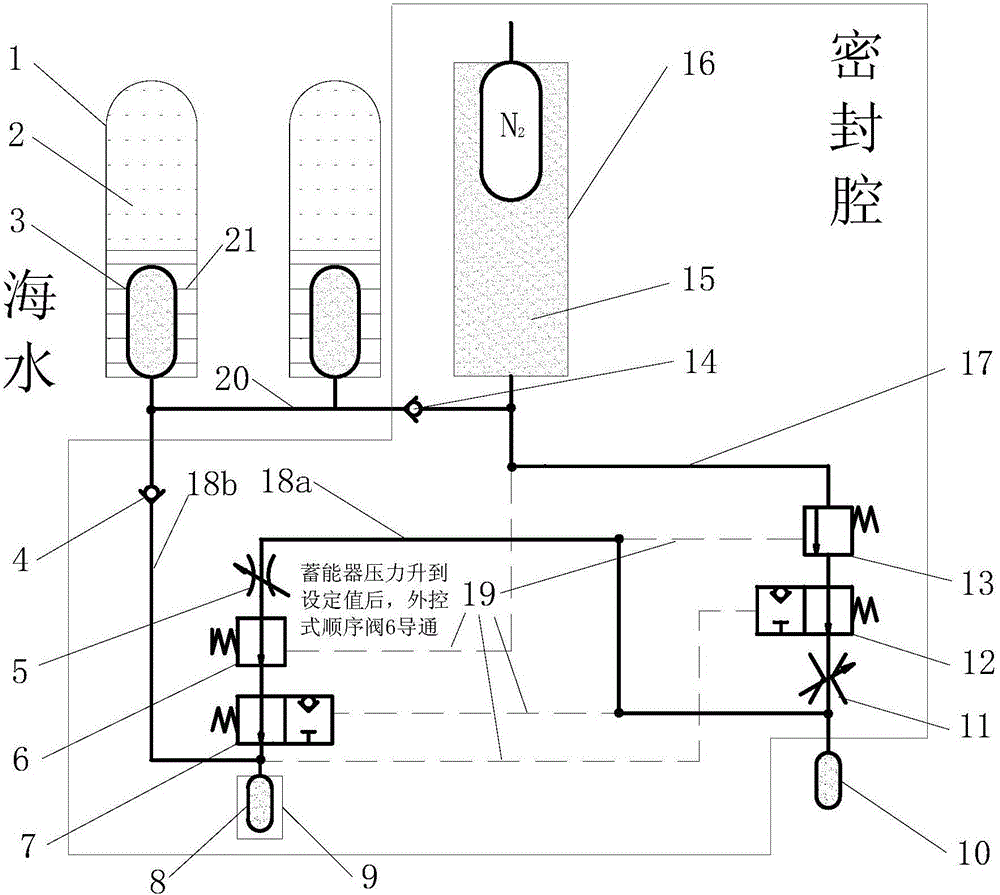

[0043] Further illustrate the present invention below in conjunction with accompanying drawing.

[0044] refer to figure 1 , an energy-saving temperature difference energy-driven ocean profile motion system of the present invention includes: a phase change chamber 1, a phase change hydraulic oil bladder 3, a one-way valve 4, a throttle valve 5, an externally controlled sequence valve 6, a hydraulic control cut-off Reversing valve 7, inner oil bag 8, sealing cavity 9, outer oil bag 10, precision throttle valve 11, hydraulic control cut-off reversing valve 12, external control sequence valve 13, one-way valve 14, accumulator 16; and the oil passages connecting these components: oil outlet passage 20, oil inlet passage 17, oil return passage 18a, oil return passage 18b and multiple control oil passages 19.

[0045] figure 1 Among them, there are two phase change chambers 1 . The phase-change hydraulic oil bag 3 is installed in the phase-change chamber 1, and the spare part i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com