Intelligent electric driving cylinder device

A technology for driving cylinders and cylinder devices, which is applied in the direction of fluid pressure actuators, power control mechanisms, door/window accessories, etc., can solve the problems of poor stability of steel springs, increased bearing capacity, and overall bulkiness, etc., to reduce the overall length , prevent the rotation of the cylinder liner, and the effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

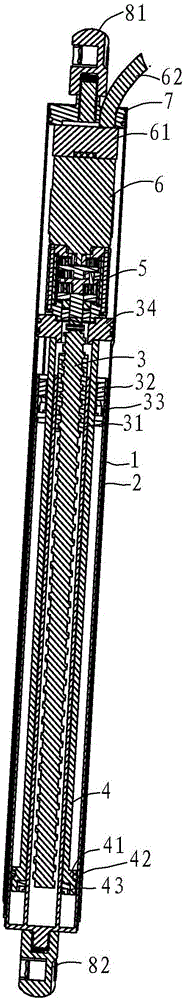

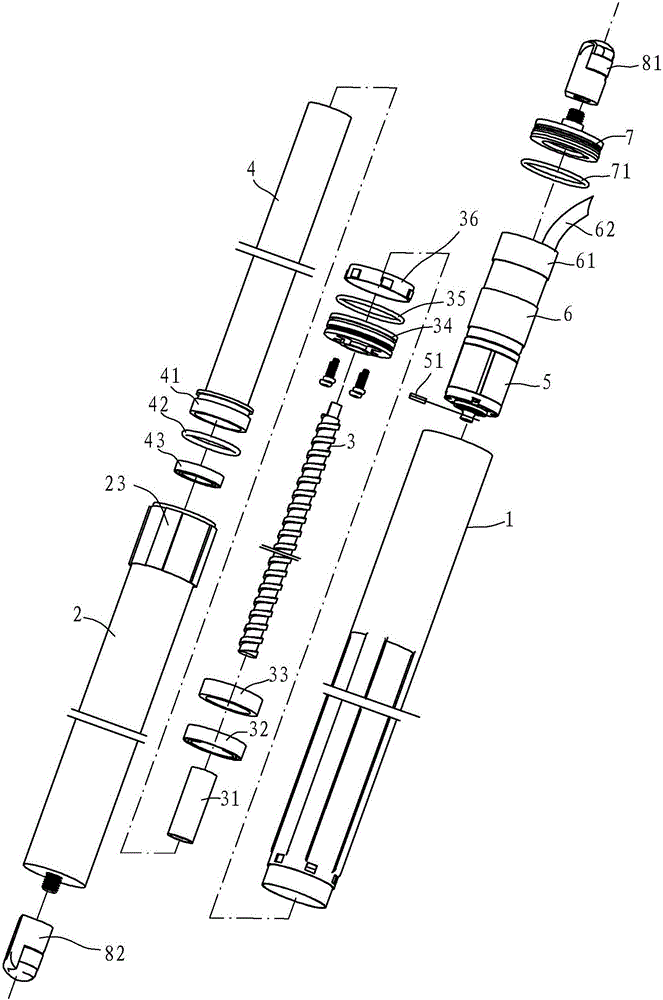

[0038] Such as Figure 1 to Figure 6 As shown, the intelligent electric drive cylinder device in this embodiment can be applied to the lifting of the tailgate of an automobile, and specifically includes an outer tube 1, a DC motor 6, a reducer 5, a cylinder liner 2, a piston rod 4, a wire sleeve 31, a multi-thread Rod 3 and positioning sleeve 33.

[0039] The front end of the outer tube 1 is provided with a waterproof ring 36, which is in close contact with the outer wall of the cylinder liner 2, the end of the outer tube 1 is provided with an outer tube cover 7, and the outer tube cover 7 is provided with an O-ring 71. The ball stud connecting part 81 is arranged on the outer tube cover 7, and the outer tube cover 7 is provided with a large O-ring.

[0040] The DC motor 6 is arranged inside the outer tube 1 and is provided with a sensor 61....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com