Transverse deformation measuring system and method based on laser irradiation intensity variation

A technology of laser irradiation and intensity change, which is applied in the field of measurement, can solve the problems that dynamic deformation cannot be continuously measured, and achieve the effects of simple and clear measurement methods and principles, ensuring the real state, and simple and convenient data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0039] The measurement method of the invention converts the mechanical deformation into the change of the light intensity of the light spot projected on the photodetector, and the photodetector converts the change of the light intensity into an electrical signal that can be directly measured.

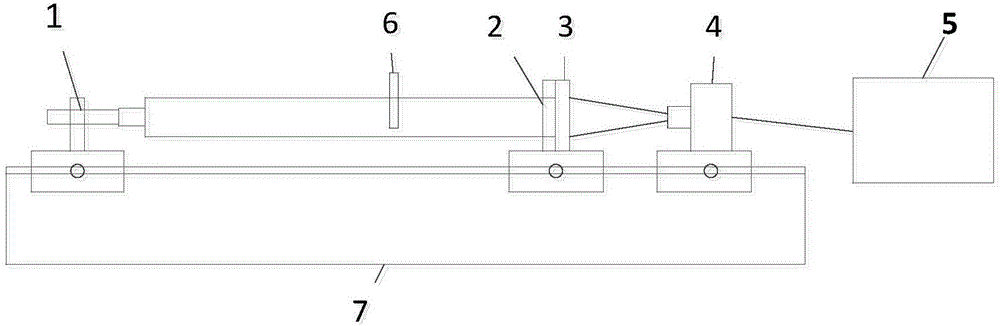

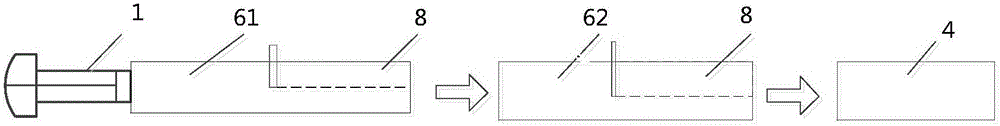

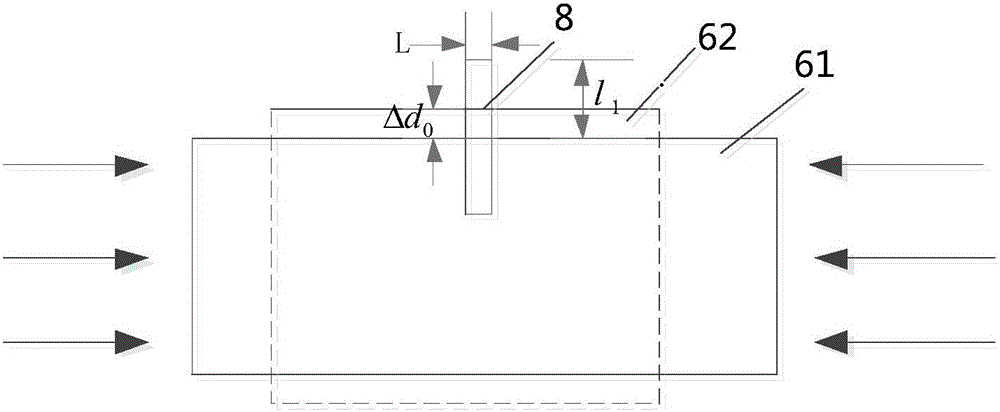

[0040] The measurement principle of the present invention is: the laser 1, the focusing lens 3, and the photodetector 4 are all placed on the support frame 7, and the geometric centers should be kept on an axis, and their main planes should be parallel to each other. Such as figure 2 As shown, the laser 1 emits a rectangular spot with a length of several millimeters, and projects the spot to a specified position perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com