Finite element model correction method based on uniform temperature response monitoring value of long-span steel bridge

A uniform temperature, finite element technology, used in special data processing applications, instruments, geometric CAD, etc., can solve the problems of large number of sensors, large data processing capacity, noise interference, etc., and achieve good stability and robustness. , the input and output are clear, the effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

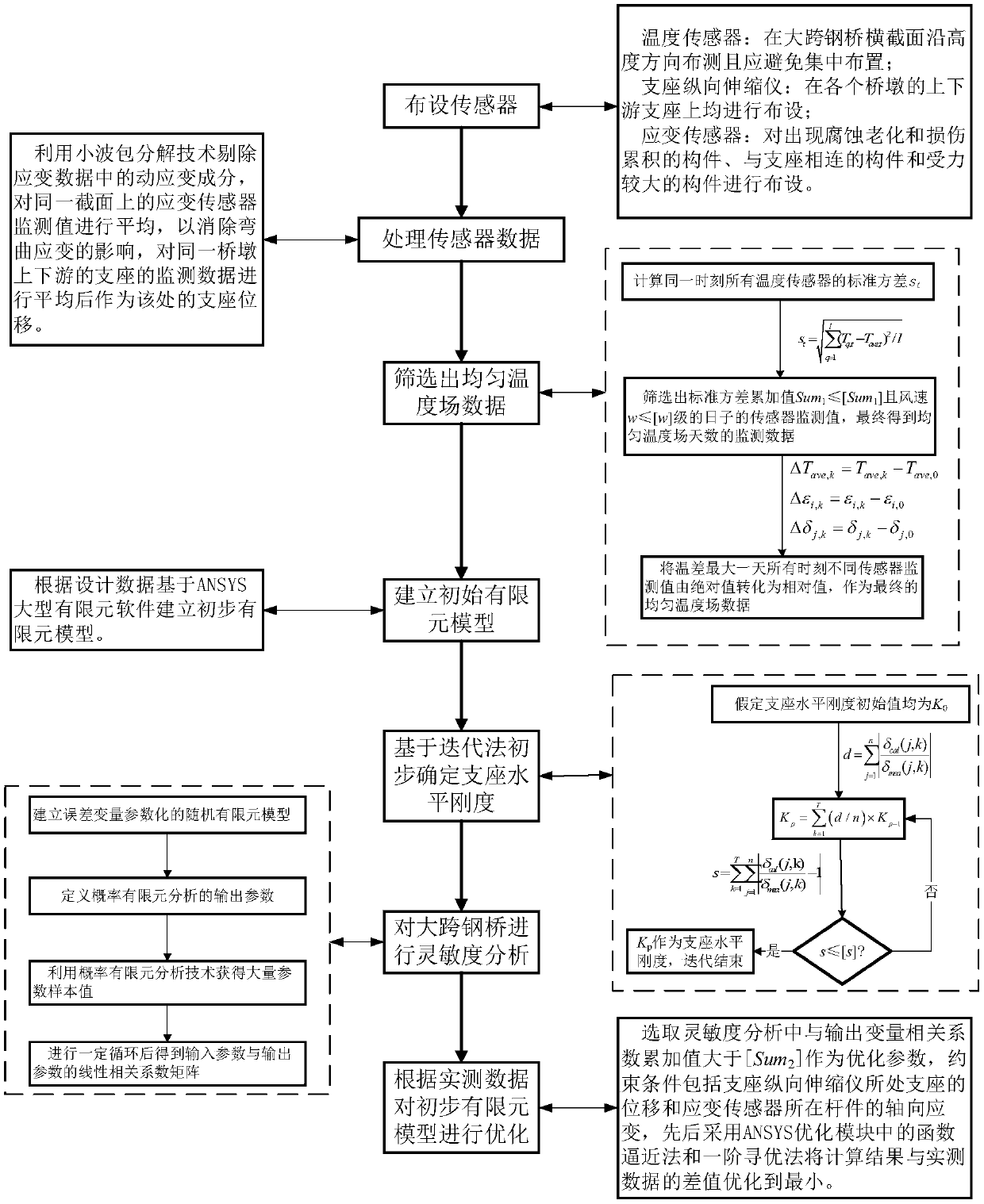

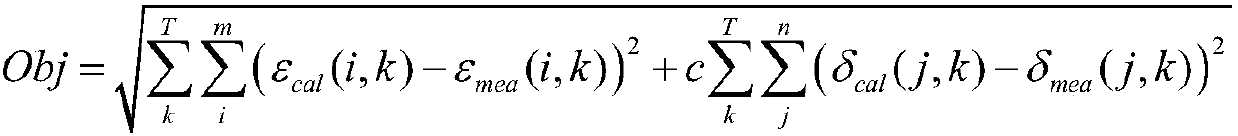

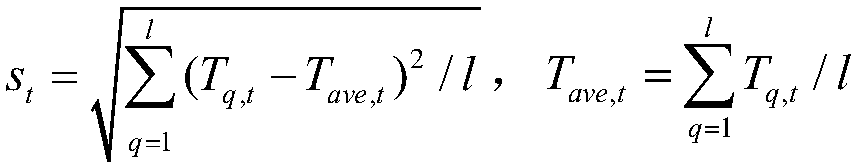

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0042] 1) Install temperature sensors, strain and displacement sensors on long-span steel bridges:

[0043] Temperature sensors are installed on arch ribs, suspenders, bridge decks, and members of the transverse and longitudinal beam systems at typical sections such as arch tops and arch feet of arch bridges. Temperature sensors are arranged on the cables, bridge deck and each member of the transverse and longitudinal beam system to monitor the change of the temperature field of the long-span steel bridge along the height direction of the typical section of the bridge. In addition, when temperature sensors are arranged on the section of each component, they should be arranged at the upper and lower ends along the height direction of the section to monitor the change of the temperature field along the section direction of the component.

[0044] Strain sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com