Self-supporting car washing method and car washer

A self-service, car-washing technology, applied in vehicle exterior cleaning devices, instrument-controlled coin-operated equipment, and coin-operated equipment for distributing discrete items, etc., can solve problems such as time delay, discount on cleaning effects, and waste of water resources , to avoid losses, avoid cleaning dead corners, and achieve the effect of safety and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

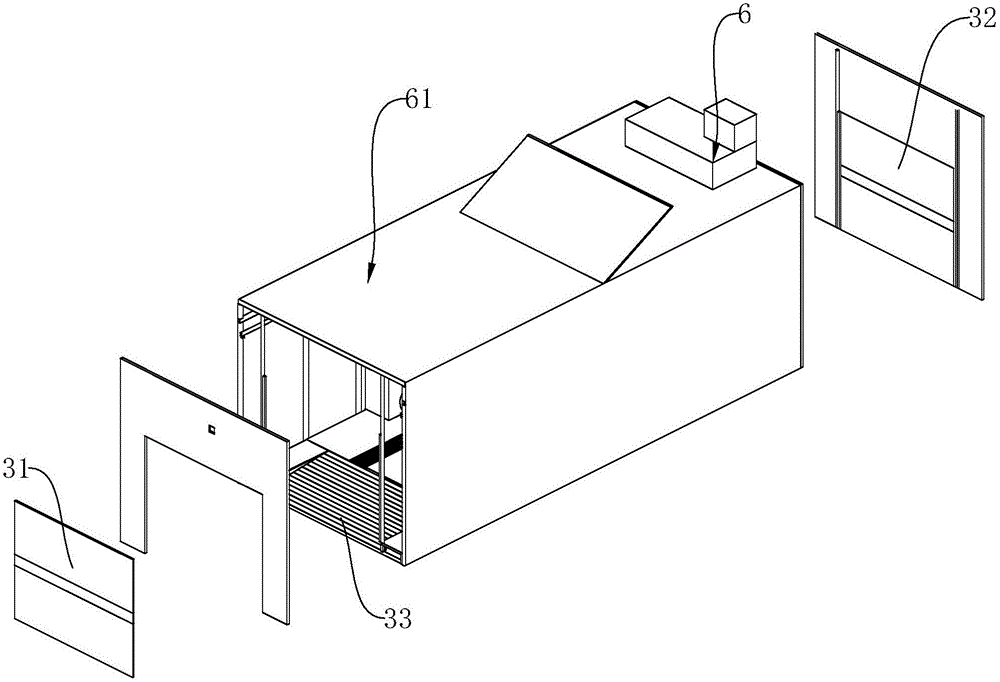

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

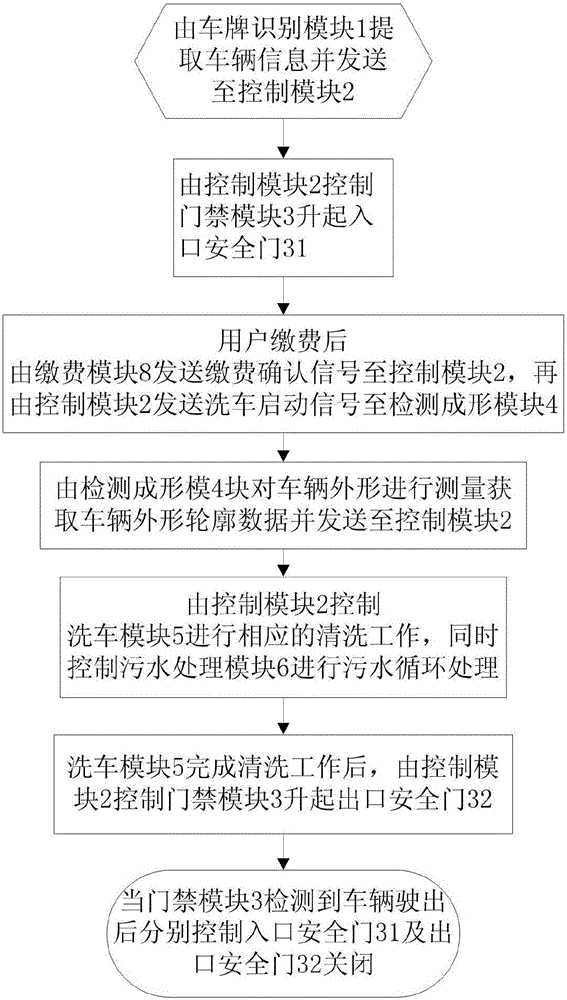

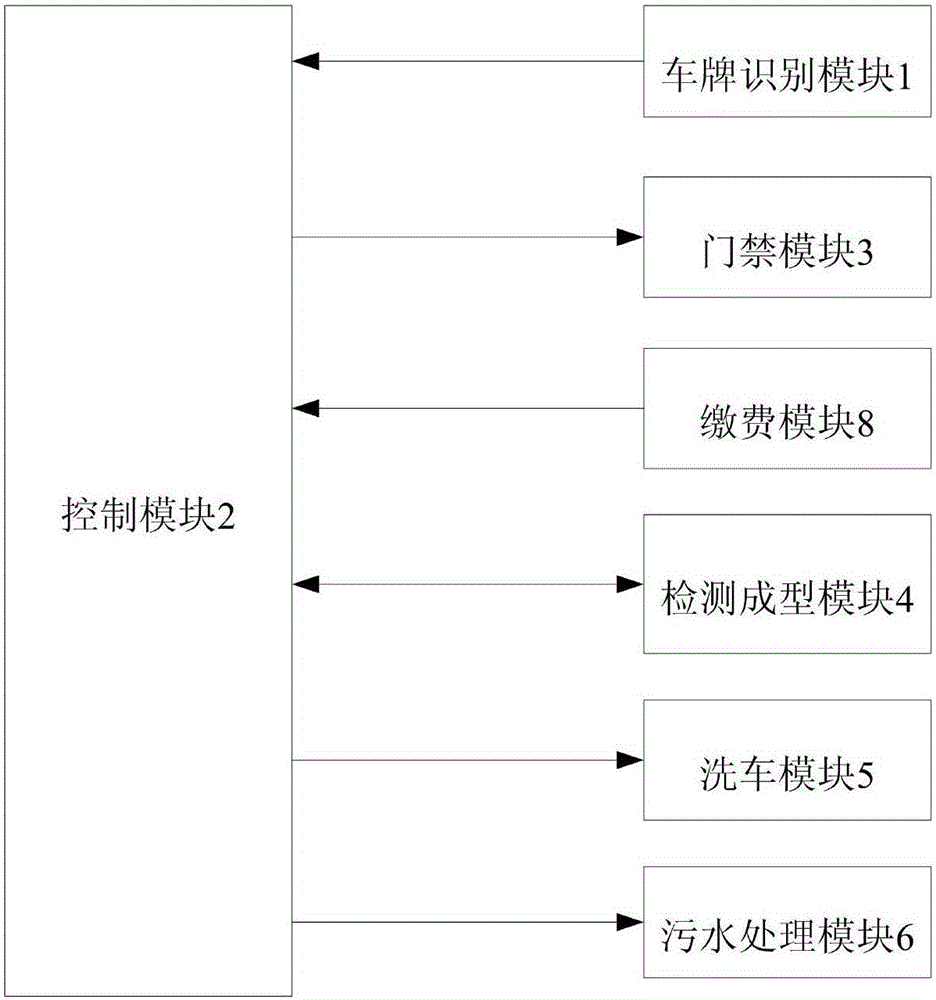

[0041] The invention provides a self-service car washing method, such as figure 1 shown, including the following steps:

[0042] 1) The vehicle information is extracted by the license plate recognition module 1 and sent to the control module 2;

[0043] 2) The received vehicle information is identified by the control module 2, and when the identification result meets the set conditions, the control module 2 sends the first opening information to the access control module 3, and the access control module 3 controls the entrance security door 31 to automatically rise;

[0044] 3) After the customer pays in the payment module 8 through the mobile terminal, the payment confirmation signal is sent to the control module 2 by the payment module 8, and then the car washing start signal is sent to the detection and forming module 4 by the control modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com