Automated string production device and method

A production device and string technology, applied in the direction of stringed instruments, instruments, etc., can solve the problems that it is difficult to meet the requirements of mass production and high quality, and achieve the effects of convenient debugging and maintenance, simple structure, and avoiding development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

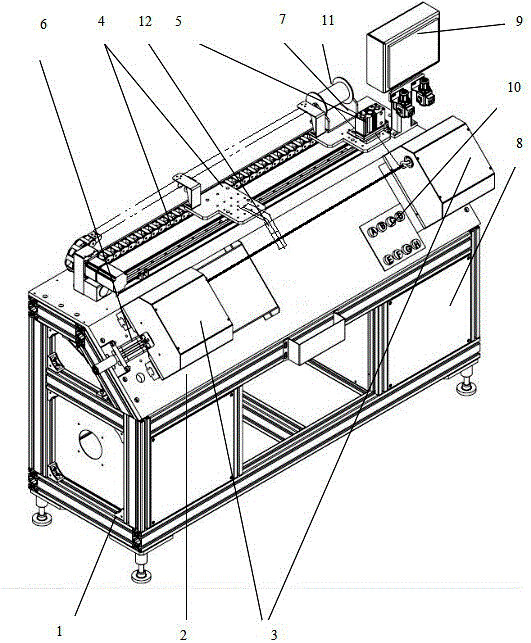

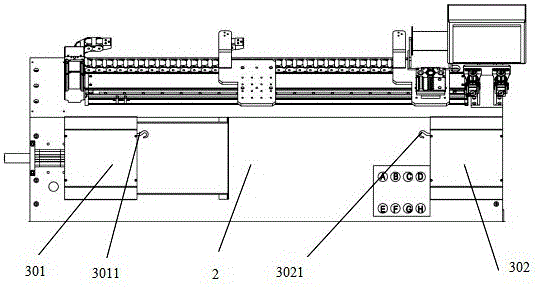

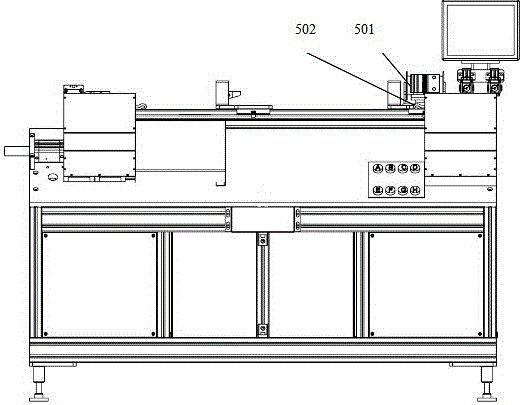

[0026] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

[0027] An automatic string production device is characterized in that it includes a frame, and the frame includes a working platform, and the working platform includes a high-speed rotating device on the left side and a high-speed rotating device on the right side, and the high-speed rotating device on the left side The high-speed rotating device and the high-speed rotating device on the right side respectively include a housing, and the parts where the high-speed rotating device on the left side and the high-speed rotating device on the right side face each other include the hook on the left side and the hook on the right side, and the hook on the left side and the hook on the right side. The side hooks are respectively located at the end of a rotating shaft, the rotating shaft is located inside the housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com