Remote coal mill monitoring system and method

A remote monitoring and coal mill technology, applied in electrical program control, comprehensive factory control, grain processing, etc., can solve problems such as unrealistic costs, achieve the effect of reducing accident rate, improving service efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

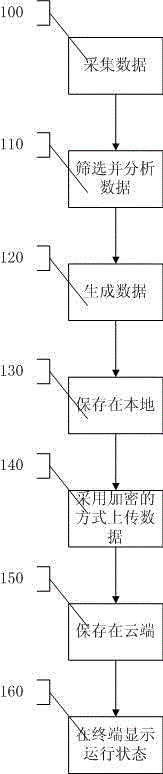

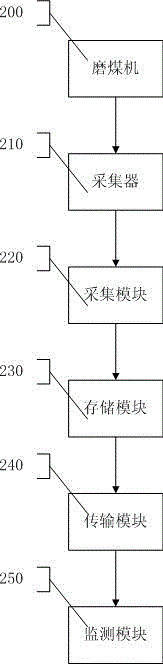

[0060] Such as Figure 1-2 As shown, step 100 is executed, the collector 210 collects the operation data of the coal mill 200 and sends it to the collection module 220 . Step 110 and step 120 are executed sequentially, and the acquisition module 220 screens and analyzes the real-time data of the coal mill 200 sent by the collector 210, and generates real-time operating data and alarm data (including the time, place, and occurrence of the abnormality) according to the operating data. Such problems, etc.), the module 220 summarizes the historical operating parameters of the coal mill 200, generates a curve, makes a historical parameter report, and makes the alarm data into an alarm parameter report. Step 130 is executed, and the collection module 220 saves the real-time operation data, alarm data, historical parameter report and alarm parameter report in the local memory in the storage module 230 .

[0061] Steps 140 and 150 are executed sequentially, and the real-time operatio...

Embodiment 2

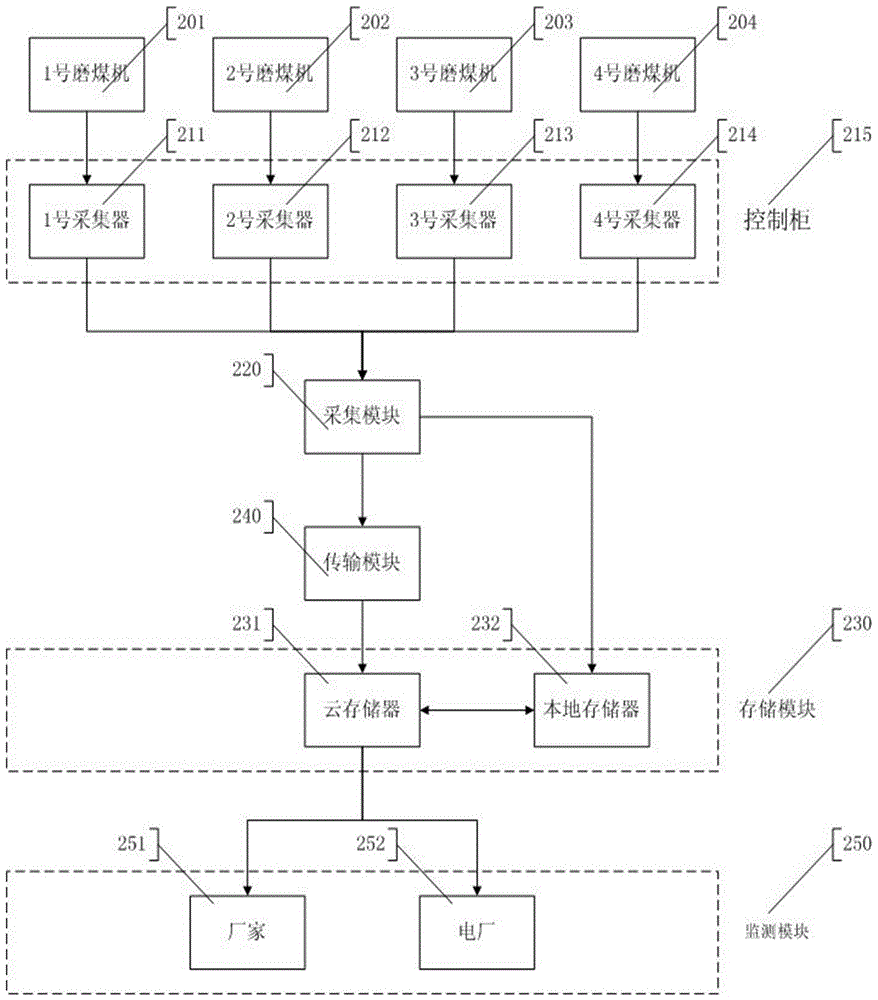

[0063] Such as image 3 As shown, No. 1 collector 211, No. 2 collector 212, No. 3 collector 213 and No. 4 collector 214 are installed in the control cabinet 215. No. 1 collector 211 collects the operation data of No. 1 coal mill (including Coal volume, actual output of the system, vibration value, loading pressure, main motor power and current and voltage, speed of separator, power and current and voltage of main motor of powder separator, oil temperature of lubricating oil station, temperature of grinding roller, temperature of thrust tile of reducer , the opening and closing degree of various electric control valves of the mill, the sealing air volume, the temperature of the primary air entering the mill, the temperature of the mill outlet and the water spray volume) and transmit it to the acquisition module 220. The No. 2 collector 212 collects the operation of the No. 2 coal mill Data (including coal input, actual output of the system, vibration value, loading pressure, ma...

Embodiment 3

[0067] Such as Figure 4 As shown, the collectors used to collect real-time operation data of coal mills are all integrated in the control cabinet 215, and the control cabinet 215 collects the No. 1 coal mill 201, No. 2 coal mill 202, and No. 3 coal mill collected by the collector. The real-time operation data of coal mill 203 and No. 4 coal mill 204 (including coal input amount, actual output of the system, vibration value, loading pressure, main motor power and current and voltage, speed of classifier, power and current and voltage of main motor of classifier , lubricating oil station oil temperature, grinding roller temperature, reducer thrust tile temperature, opening and closing degree of various electronic control valves of the mill, sealing air volume, primary air entering the mill temperature, mill outlet temperature and water spray volume, etc.), and through The RS485 communication interface sends to the acquisition module 220. The acquisition module 220 screens and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com