Automatic hanger machining device

An automatic processing and hanger technology, applied to wire processing, other household appliances, household appliances, etc., to achieve the effect of high automation level, high production efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

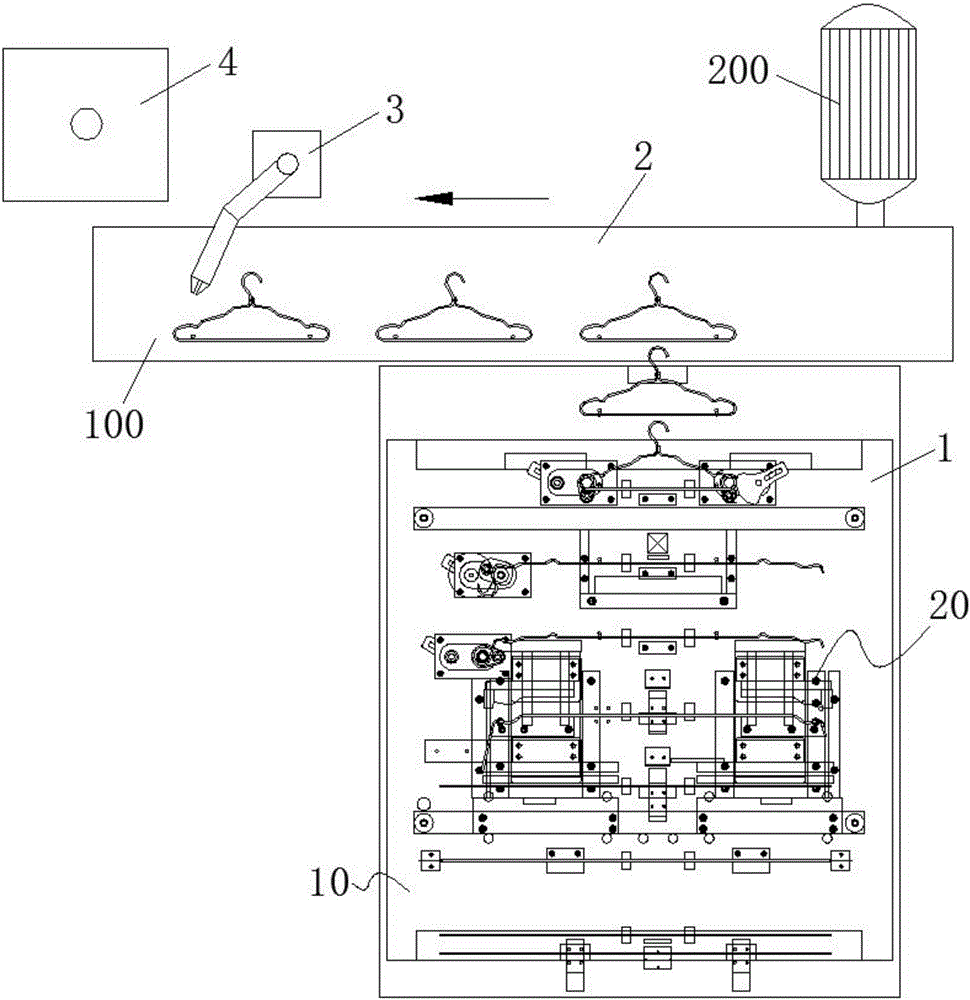

[0044] see Figure 1-Figure 14 . The automatic hanger processing device of the present invention includes a bending forming machine 1, a transmission mechanism 2, an automatic picker 3 and a nailing machine 4, and the transmission mechanism 2 is arranged on the bending forming machine 1 and the automatic picker 3 In between, the nailing machine 4 is arranged on one side of the automatic picker 3; the bending forming machine 1 is used to bend and shape the raw material into a semi-finished hanger, and the conveying mechanism 2 is used to transfer the semi-finished hanger from The bending forming machine 1 is transferred to the automatic picker 3, and the automatic picker 3 is used to pick up the semi-finished hanger on the transfer mechanism 2 and place it on the nailer 4 for nailing.

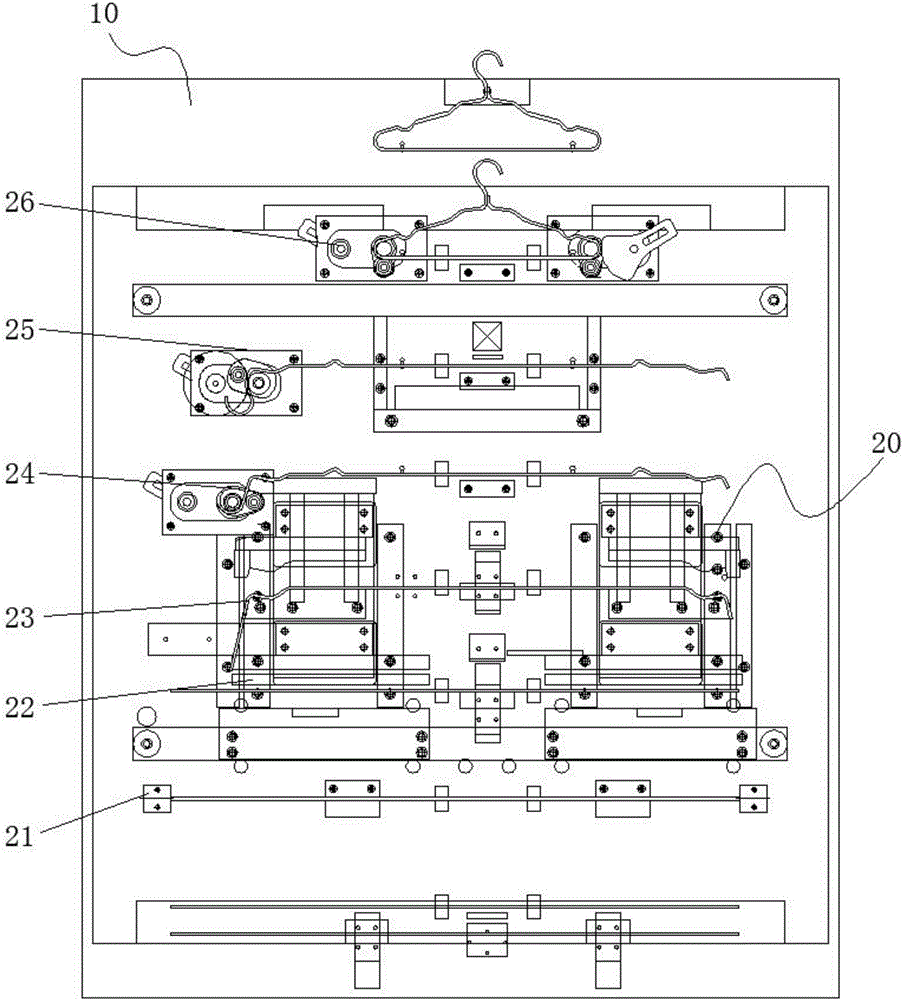

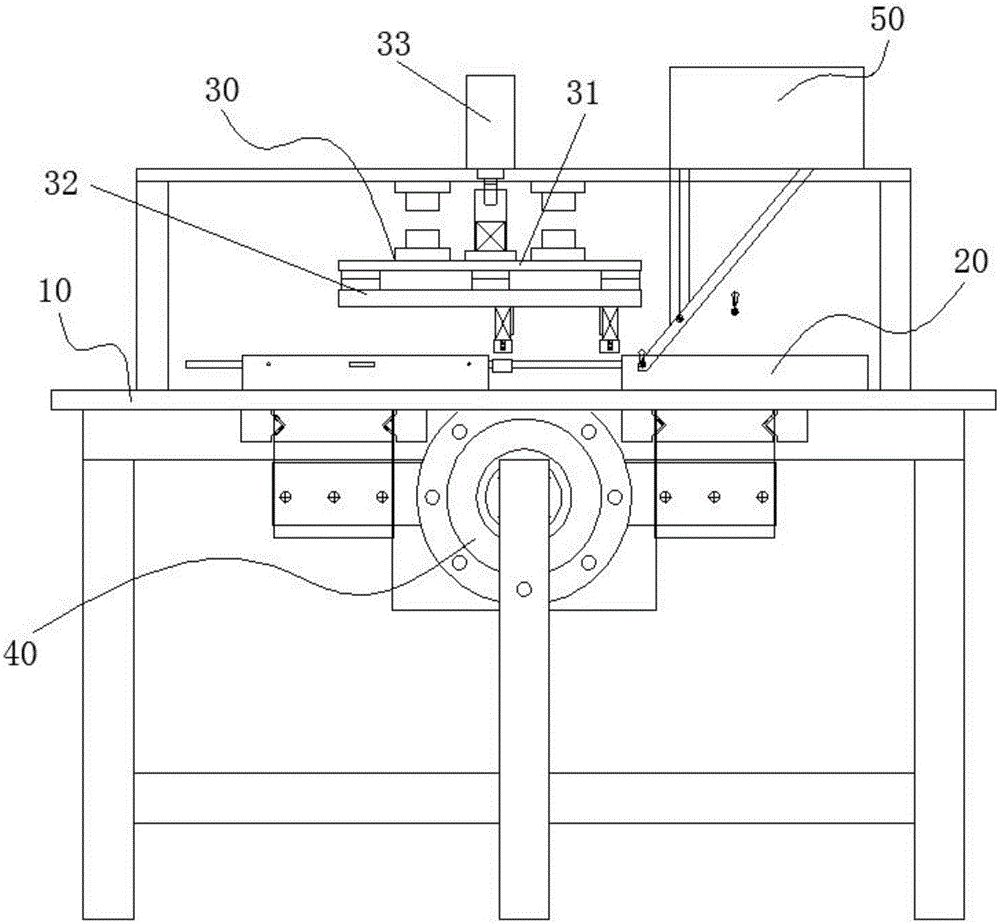

[0045]The bending and forming machine 1 includes a planar workbench 10 , a bending and forming mechanism 20 and a conveying mechanism 30 . The bending and forming mechanism 20 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com