Clutch forging and pressing mold and use method thereof

A technology of clutches and molds, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve the problems of not optimizing the overall performance of parts, low production efficiency, and prone to errors, etc. Achieve the effect of saving raw materials and energy, high production efficiency and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

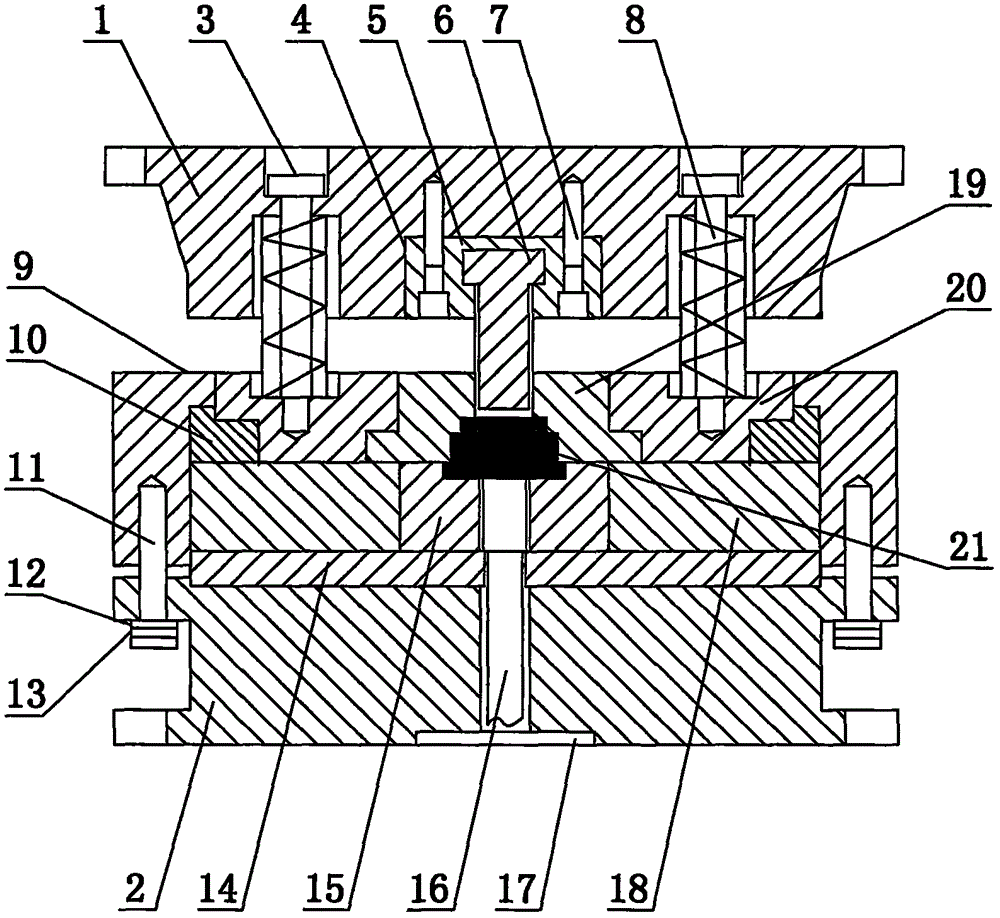

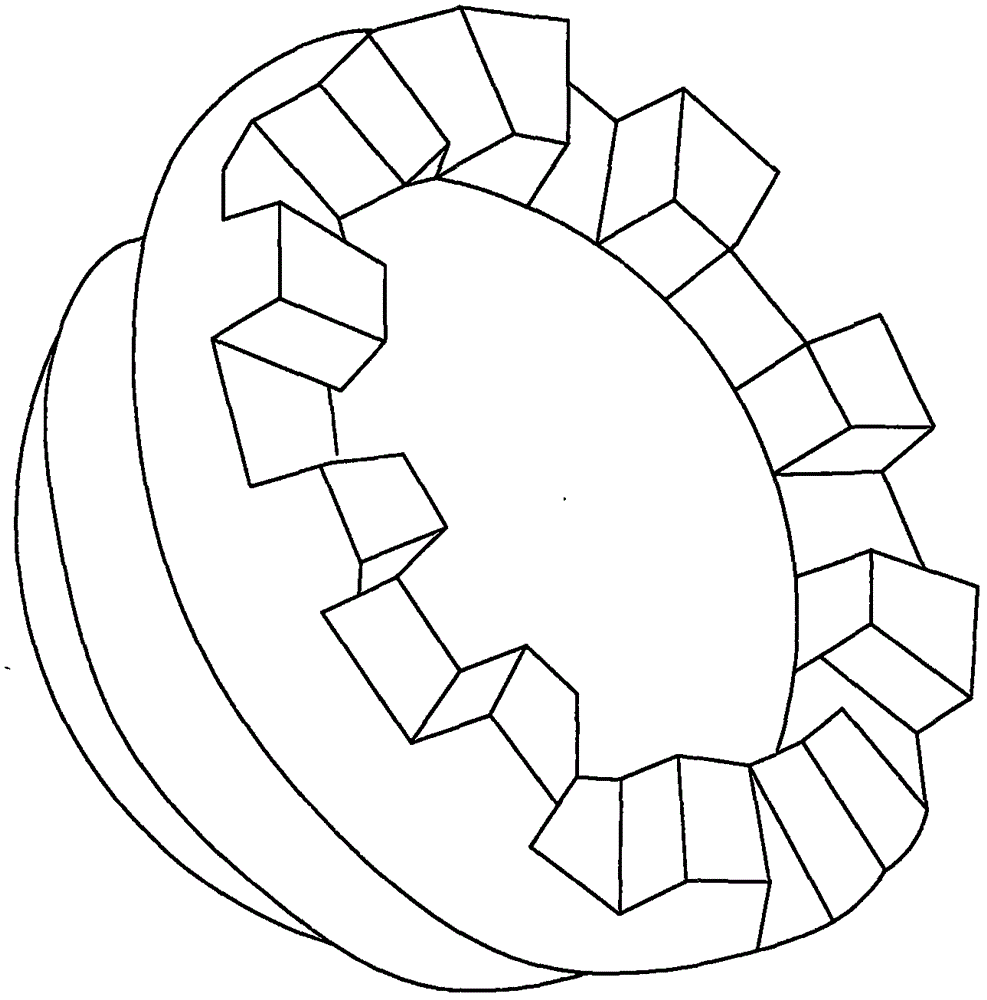

[0024] like figure 1 and figure 2 Shown, a kind of clutch forging die, it comprises upper mold base 1 and lower mold base 2, described upper mold base 1 is equipped with pull rod 3, and described pull rod 3 is provided with return spring 8, described upper die base 1 A punch holder 4 is installed, and the punch holder 4 is equipped with a connecting screw A7, and a backing plate 5 is installed inside the punch holder 4, and the punch holder 4 is connected with a punch Rod 6, the lower mold base 2 is connected with a compression collar 9, the connecting screw B11 is connected between the lower mold base 2 and the compression collar 9, and the upper end of the lower mold base 2 is installed with Lower mold spacer 14, the upper end of the lower mold spacer 14 is equipped with a die 45 and a stress ring 18, the upper end of the die 15 is equipped with a guide mold 19, and the guide mold 19 is equipped with a guide mold press ring 20, the guide die holder 20 is equipped with a p...

Embodiment 2

[0034] like figure 1 and figure 2Shown, a kind of clutch forging die, it comprises upper mold base 1 and lower mold base 2, described upper mold base 1 is equipped with pull rod 3, and described pull rod 3 is provided with return spring 8, described upper die base 1 A punch holder 4 is installed, and the punch holder 4 is equipped with a connecting screw A7, and a backing plate 5 is installed inside the punch holder 4, and the punch holder 4 is connected with a punch Rod 6, the lower mold base 2 is connected with a compression collar 9, the connecting screw B11 is connected between the lower mold base 2 and the compression collar 9, and the upper end of the lower mold base 2 is installed with Lower mold spacer 14, the upper end of the lower mold spacer 14 is equipped with a die 45 and a stress ring 18, the upper end of the die 15 is equipped with a guide mold 19, and the guide mold 19 is equipped with a guide mold press ring 20, the guide die holder 20 is equipped with a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com