Tool for automatic model-selecting, positioning and tightening of gearbox mount bracket and process thereof

A suspension bracket and automatic type selection technology, applied in the field of machinery, can solve the problems of shaking, poor positioning effect, unable to maintain the consistency of tooling, etc., and achieve the effect of improving positioning accuracy, eliminating personnel actions, and eliminating manual positioning actions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

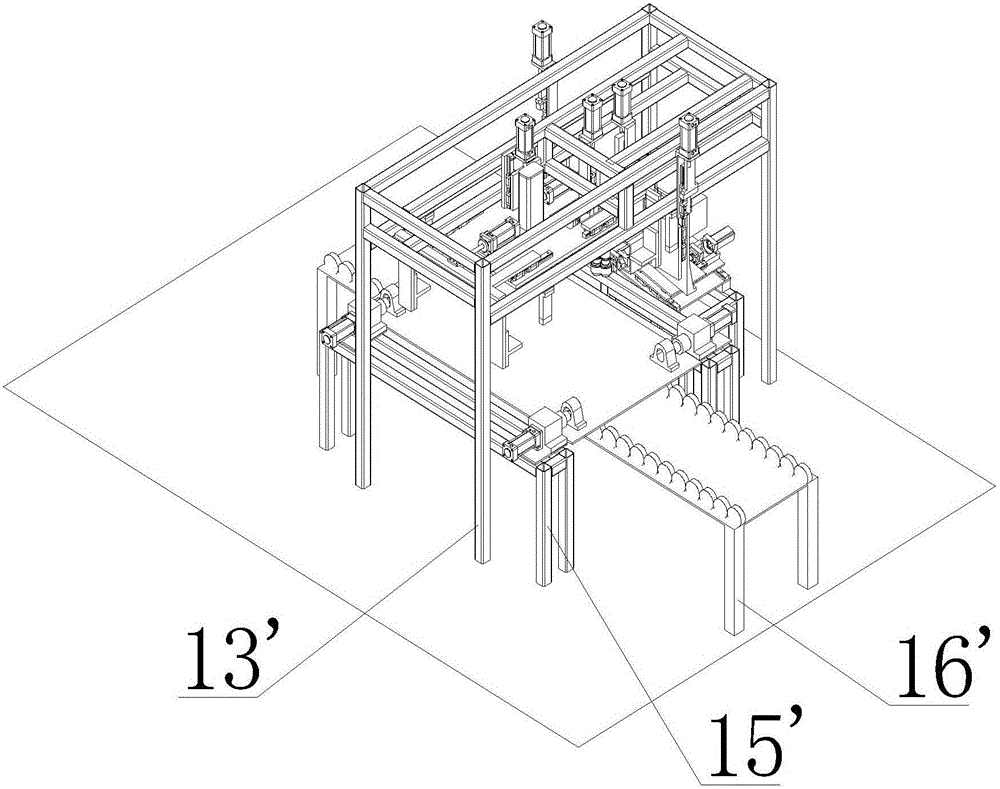

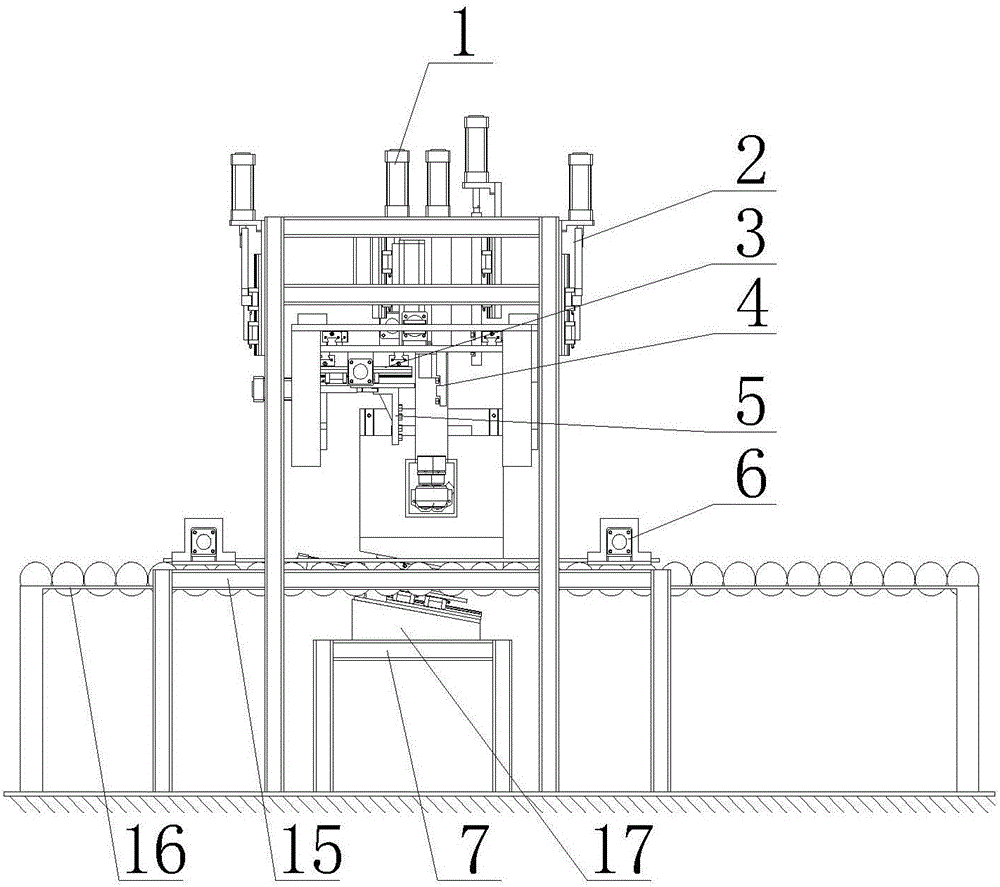

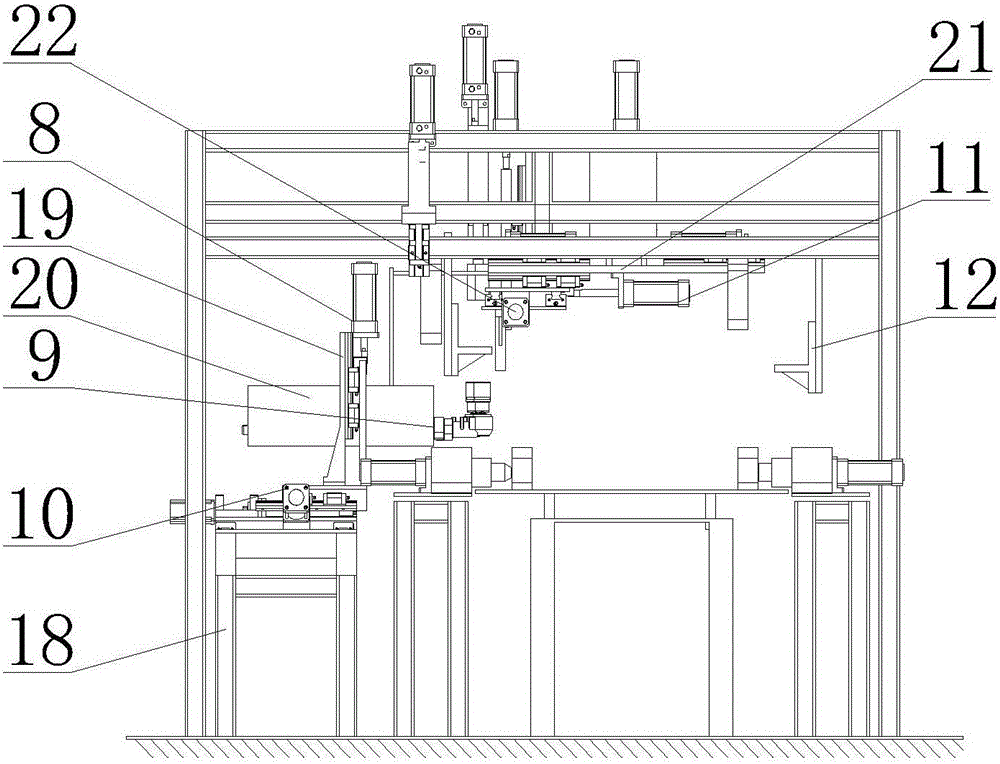

[0048] The auxiliary frame is provided with several positioning holes, and the clamp is provided with positioning pins matched with the positioning holes. When in use, the clamp clamps the secondary frame through the positioning pins and positioning holes.

[0049] The jig with the subframe is transported to the workbench 15 by the conveyor belt 14, and the jig is clamped by the jig cylinder 6, and the lifting platform 21 is driven by the lifting cylinder 1, so that the subframe is lifted. During the process, the positioning hole on the subframe is separated from the positioning pin on the fixture. After the positioning hole on the subframe is separated from the positioning pin, the product positioning pin on the subframe is inserted into the positioning hole, so that the system can accurately position the subframe. Vehicle frame, after the sub-frame is lifted in place, the sub-frame is clamped by the positioning cylinder 2.

[0050] Identify whether the sub-frame to be proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com