Heat transfer film cutting device with function of freely regulating cutters

A thermal transfer film and cutting technology, applied in metal processing and other directions, can solve the problems of inability to relatively adjust the spacing and angle, time-consuming and laborious disassembly and replacement, affecting production efficiency, etc., to improve market competitiveness, increase work cooperation, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

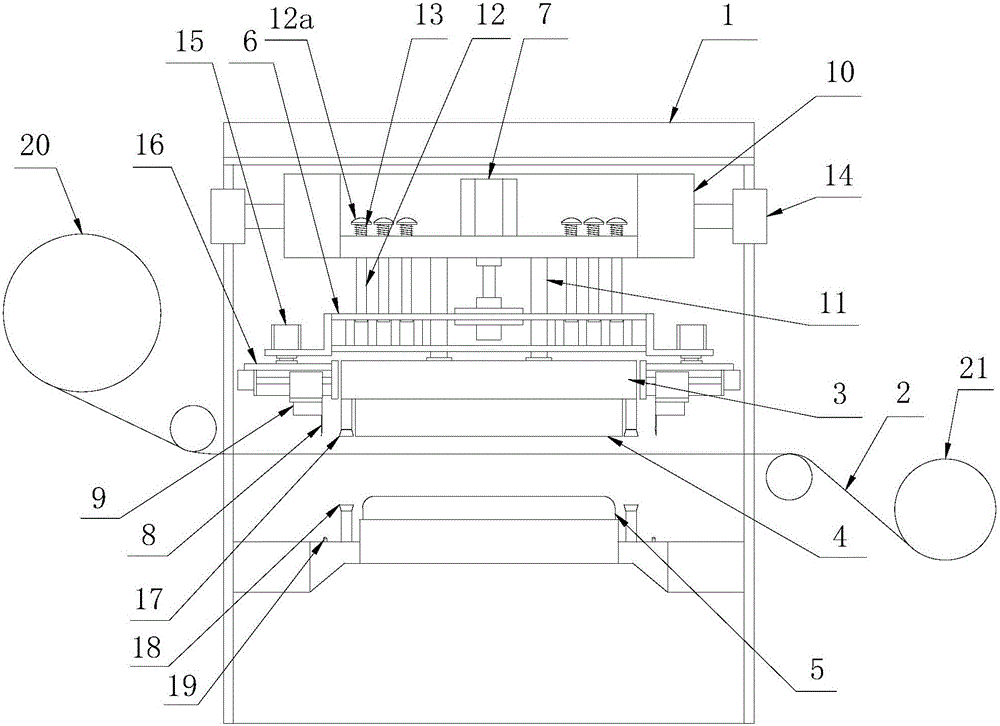

[0025] Example: as shown in the figure 1 Shown is a specific embodiment of a thermal transfer film cutting device with a cutter free adjustment function of the present invention, which has a bracket 1 , Set on the bracket through the lifting drive mechanism 1 The positioning and cutting mechanism of the thermal transfer film on the upper surface, the substrate positioning mechanism arranged under the positioning and cutting mechanism of the thermal transfer film, and the positioning mechanism for the thermal transfer film 2 The reel mechanism conveyed through the middle of the cutting mechanism and the positioning mechanism. The reel mechanism described in the present embodiment has unwinding roller as conventional technology 20 and winding roller 21 ,by PLC The controller (not shown in the figure) controls the thermal transfer film 2 delivery. The lifting drive mechanism is a lifting cylinder (not shown in the figure), and the lifting cylinder is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com