Composite film for milk powder package

A packaging and composite film technology, applied in the field of edible packaging, can solve the problem of high product cost, and achieve the effects of good mechanical properties, good environmental protection, and excellent heat sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

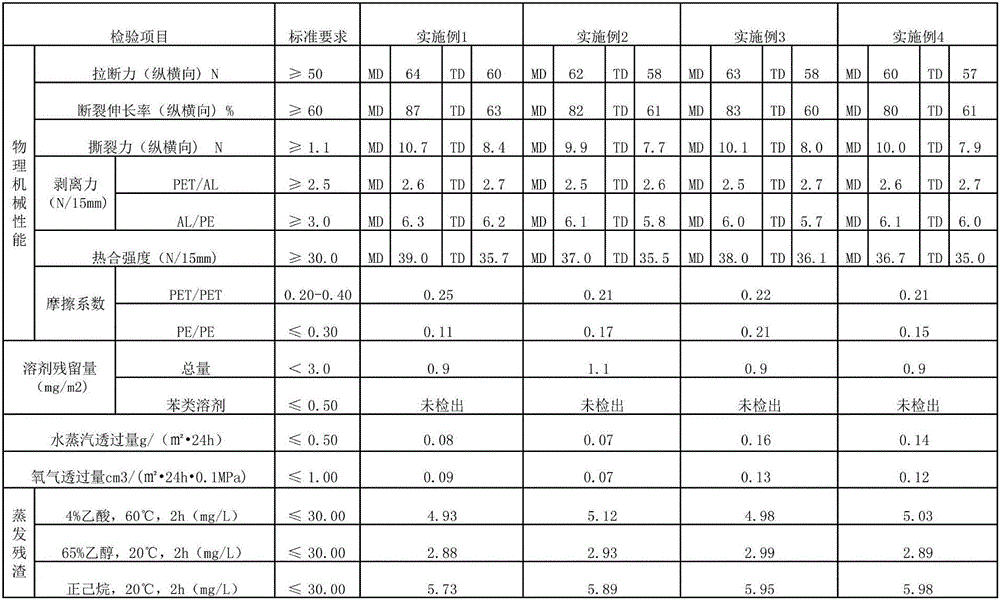

Examples

preparation example Construction

[0026] The preparation method of the polyethylene layer is as follows: add the composite layer resin, the middle layer resin and the heat-sealing layer resin into the three barrels of the extruder, and heat each barrel in three stages, and the heating temperature of each barrel is 120 ~130℃, the second-stage heating temperature is 130-140℃, the third-stage heating temperature is 140-150℃, the die temperature is 140-160℃, and the extrusion melt pressure is controlled to be less than 45Mpa. The polymer particles in the above three barrels are melted by the extruder and formed into a tube blank. After the tube blank is stretched, compressed air is blown out from the center of the extruder die head to inflate the tube blank into a bubble film, and the bubble The shaped film is cooled and shaped by an air ring to obtain a polyethylene layer.

[0027] The polyethylene layer composed of the aforementioned composite layer, intermediate layer and heat-sealing layer has excellent heat-seal...

Embodiment 1

[0031] Add the composite layer resin raw material, the intermediate layer resin raw material and the heat-sealing layer resin raw material into the three barrels of the co-extrusion machine. The formula of each resin raw material is as follows:

[0032] Composite layer: 25kg of 150BW, 50kg of 5100G;

[0033] Middle layer: 25kg of 150BW, 25kg of 5100G, 25kg of F920A;

[0034] Heat seal layer: 25kg Exxon 100AC, 50kg 5401G, 1kg AB-20LD.

[0035] After the polymer particles in the above three barrels are co-extrusion blow-molded to obtain a polyethylene layer, dry composite with the PET / Al semi-finished product formed by dry composite to form the composite film of the present invention.

Embodiment 2

[0037] The resin raw material formula is as follows:

[0038] Composite layer: 22.5kg of 150BW, 52.5kg of 5100G;

[0039] Middle layer: 22.5kg of 150BW, 26.25kg of 5100G, 26.25kg of F920A;

[0040] Heat sealing layer: 24.32kg Exxon 100AC, 50.16kg 5401G, 1.52kg AB-20LD. The rest is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com