Tunneling whole-section advanced composite material casting slurry and preparation method thereof

A composite material and tunneling technology, which is applied in tunnels, tunnel linings, mining equipment, etc., to achieve the effects of improving slurry performance, improving uniformity and stability, and compensating for poor durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

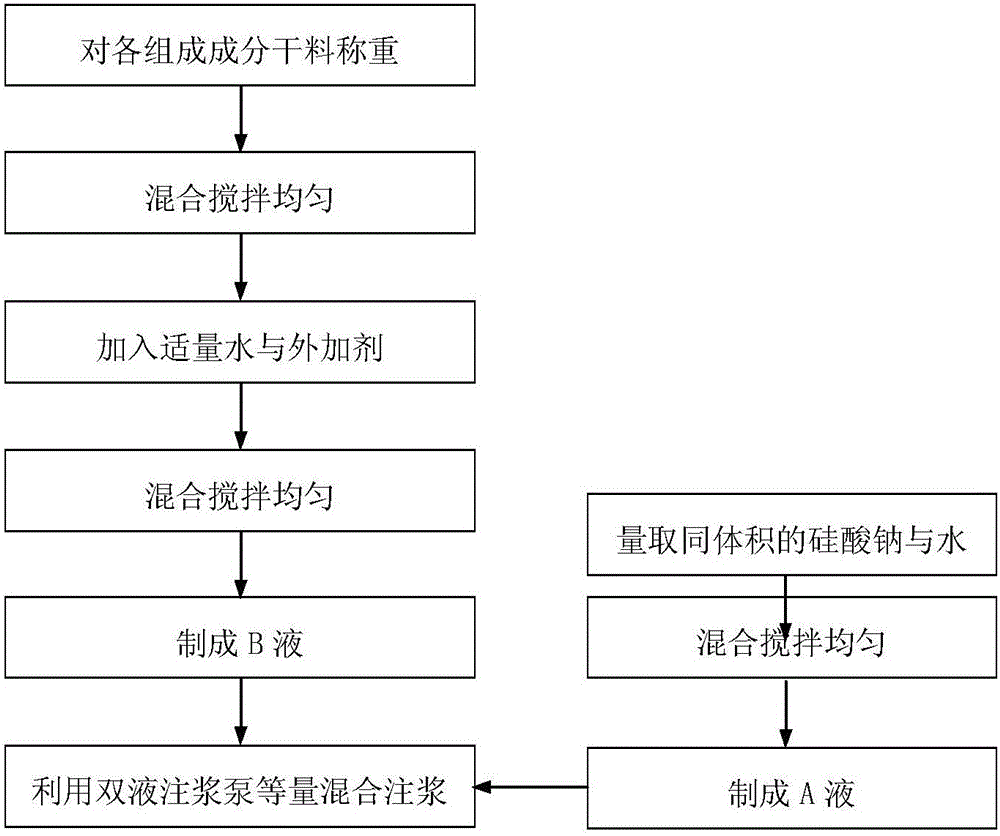

[0020] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A full-section advanced composite material grouting slurry for tunnel excavation disclosed by the invention is a mixture of modified water glass and cement-based slurry, wherein the modified water glass is liquid A; the cement-based slurry is liquid B. The modified water glass is composed of sodium silicate and water in a volume ratio of 1:1, and the cement-based slurry of the B liquid is composed of ordinary Portland cement, bentonite, admixture and water, and the admixture is XPM agent. Wherein the B liquid, that is, the mass ratio of water and ash of the cement-based slurry is 0.8:1 to 1:1, and the mass of the bentonite is 1.5% to 2% of the mass of the ordinary portland cement. %, the mixed quality of the XPM agent is 3% to 5% of the mixed quality of the ordinary Portland cement, and the rest is water; the volume ratio of the A liquid and the B liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com