A kind of environment-friendly flame-retardant waterproof agent for leather and preparation method thereof

A waterproof and environmentally friendly technology, applied in leather surface treatment, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. Easy to yellow and other problems, to achieve the effect of durable waterproof performance, environmental protection performance, and alcohol wiping resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

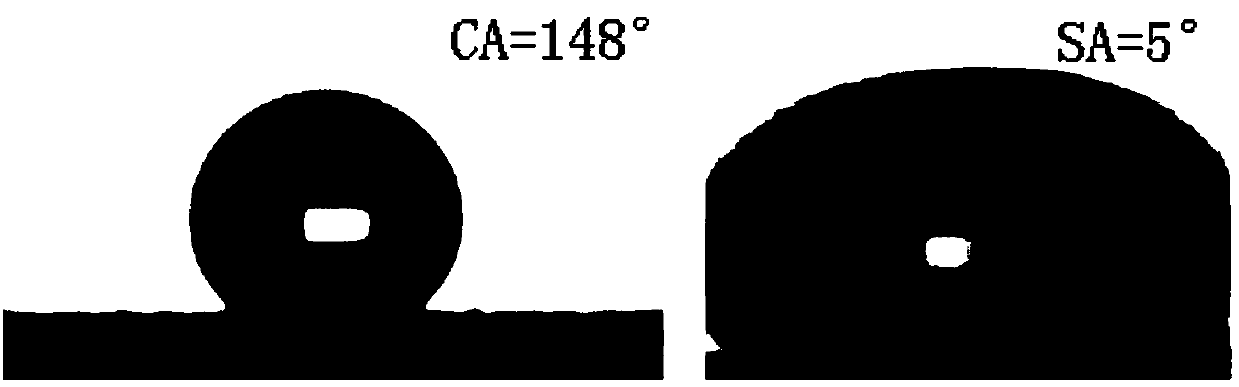

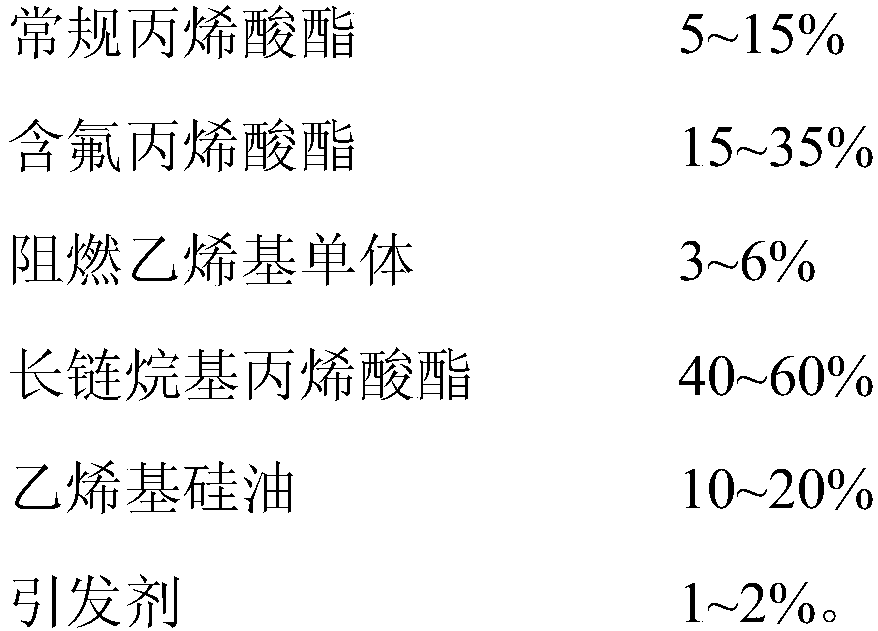

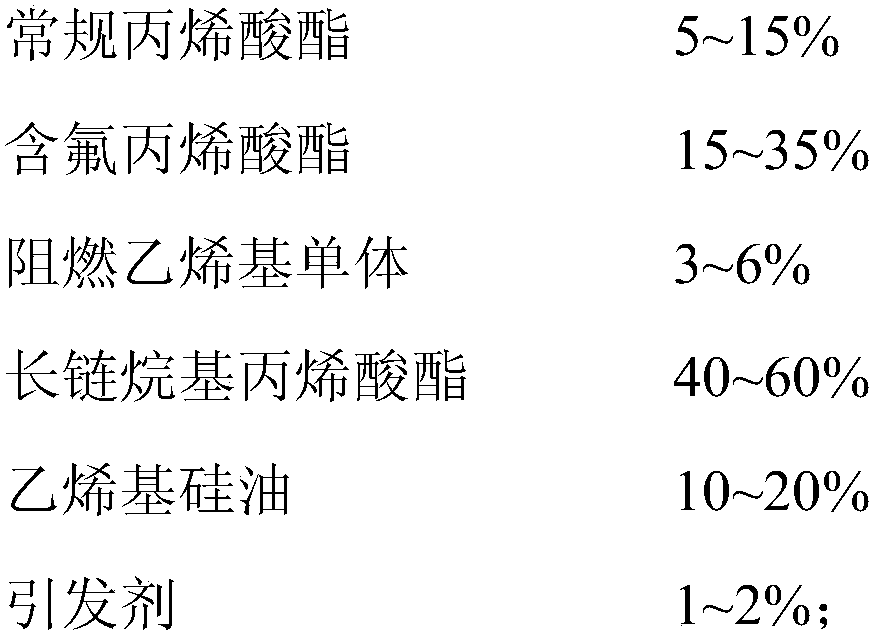

[0027] In a four-necked flask equipped with a stirrer, a thermometer, and a reflux tube, mix 2g BPO initiator, 5g acrylamide, 20g vinyl silicone oil (1000cp), 6g vinyl chloride, 40g octadecyl acrylate with 100g solvent (acetic acid 50g of ethyl ester and 50g of butyl acetate) were mixed evenly, added dropwise to the reaction vessel at 80°C for 4 hours, then 29g of dodecafluoroheptyl acrylate was added dropwise for 1 hour, and finally mechanically stirred and kept for 5 hours to obtain The uniform viscous solution is the environmentally friendly flame retardant waterproofing agent for leather. After being placed for two months, the solution does not delaminate and has good stability. Take the waterproofing agent and bake it at 100°C for 4 hours without yellowing. , Ignite the dried waterproof agent with an open flame, remove the fire source, self-extinguishing occurs, and has certain flame-retardant properties. Apply this water repellant solution to the leather finishing agent ...

Embodiment 2

[0029] In a four-necked flask equipped with a stirrer, a thermometer, and a reflux tube, put 1.5g of AIBN initiator, 15g of hydroxyethyl acrylate, 10g of vinyl silicone oil (1500cp), 3g of vinylidene chloride monomer, and 50g of hexadecyl acrylate Mix the ester with 100g of solvent (butanone) evenly, drop it into the reaction vessel at 90°C for 2 hours, then add 22g of dodecafluoroheptyl acrylate dropwise for 2 hours, and finally mechanically stir and keep warm for 3 hours to obtain a uniform viscous solution The product is the environmentally friendly flame retardant waterproofing agent for leather. The water repellent film formed by the obtained water repellant has flame retardant performance, alcohol wiping resistance, good water repellency and long-lasting water repellency.

Embodiment 3

[0031] In a four-necked flask equipped with a stirrer, a thermometer, and a reflux tube, mix 1.5g of BPO initiator, 6g of hydroxypropyl acrylate, 12g of vinyl silicone oil (500cp), 4g of vinyl chloride, 60g of dodecyl acrylate with 100g The solvent (a blend of butanone 50g and butyl acetate 50g) was mixed evenly, and added dropwise to the reaction vessel at 85°C for 3 hours, then 18g of hexafluorobutyl acrylate was added dropwise for 1.5 hours, and finally mechanically stirred and kept for 4 hours. Finally, obtain a uniform solution viscous substance, which is the environmentally friendly flame-retardant and water-repellent agent for leather. The water repellent film formed by the obtained water repellant has flame retardant performance, alcohol wiping resistance, good water repellency and long-lasting water repellency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com