Method for preparing hafnium/silicon nitride conductive and corrosion-resistant multilayer structure coating on magnesium alloy

A multi-layer structure, magnesium alloy technology, applied in the direction of metal material coating process, coating, superimposed layer plating, etc., can solve problems such as coating failure, reduce the amount of hydrogen evolution of the sample, reduce the roughness, and improve the durability The effect of erosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Substrate pretreatment

[0034] (1) Mechanical grinding and polishing treatment. First, grind the magnesium alloy on 320-mesh SiC water-grinding paper until the surface is smooth, and place it in absolute ethanol for ultrasonic cleaning for 5 minutes; then grind it on 1500-mesh SiC water-grinding paper until the scratches are in the same direction. Ultrasonic cleaning in ethanol for 5 minutes; then grinding on 3000-mesh SiC water-grinding paper along the vertical direction of 1500-mesh sandpaper scratching for 120 seconds, ultrasonic cleaning in ethanol for 5 minutes; Direction Gently grind for 120s until there are no obvious scratches on the surface, then place it in ethanol for ultrasonic cleaning for 15min. Use a diamond polishing spray with a particle size of 2.5 μm to rough polish the grinding sample for 60 seconds until the surface is bright; then use a diamond polishing paste with a particle size of 1 μm and 0.5 μm to perform fine polishing on the polishing di...

Embodiment 2

[0047] 1. Substrate pretreatment

[0048] (1) Mechanical grinding and polishing treatment, same as embodiment 1.

[0049] (2) chemical etching, same as embodiment 1.

[0050] (3) The ion source bombardment cleaning treatment is the same as that in Embodiment 1.

[0051] 2. Metal Hf, pure Si 3 N 4 The pre-sputtering of the target is the same as in Example 1.

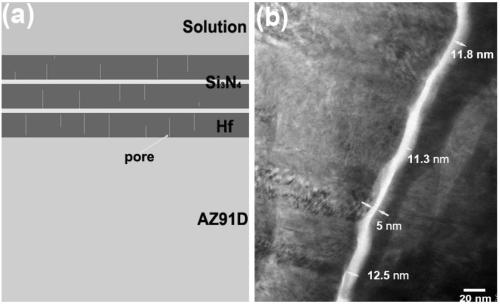

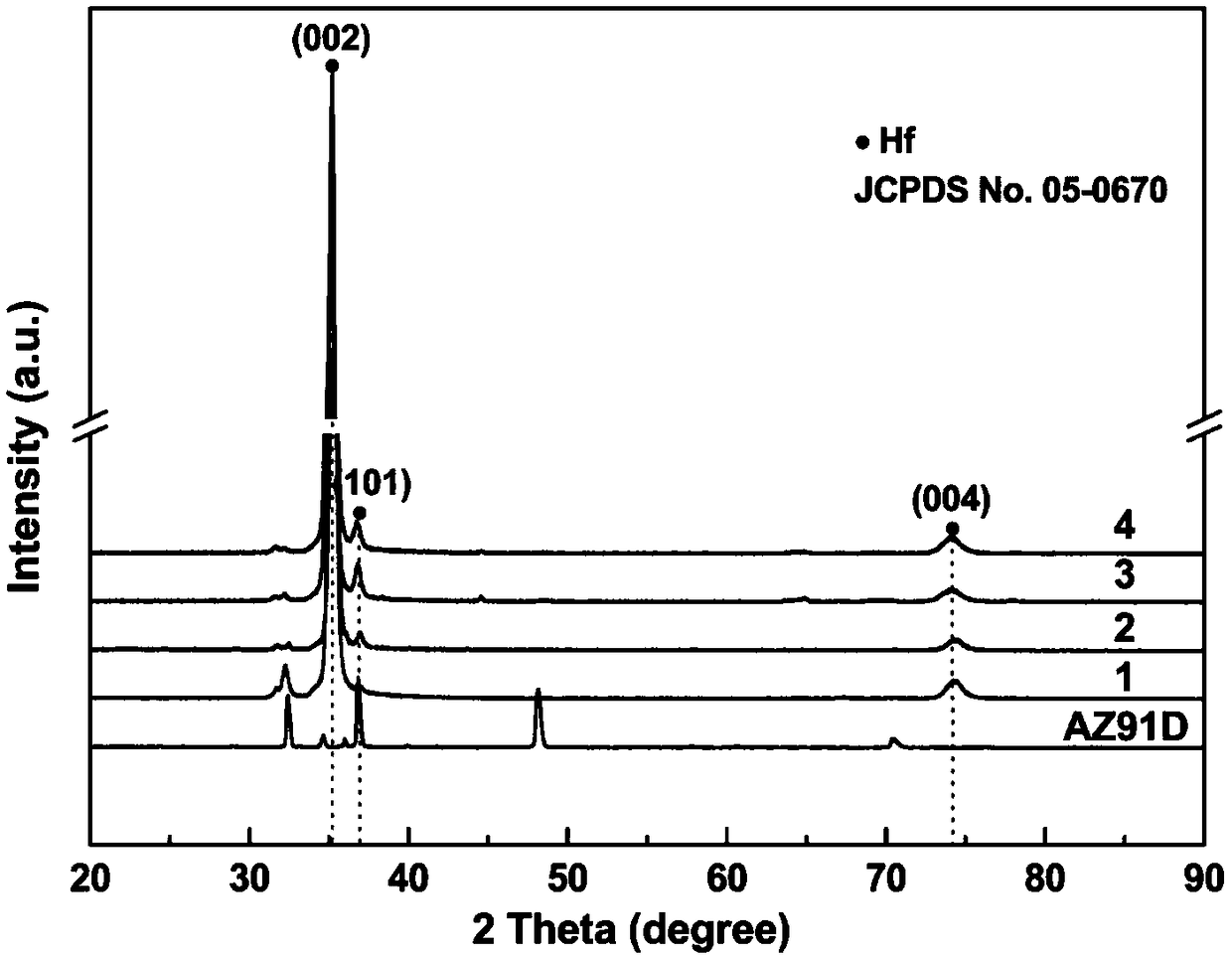

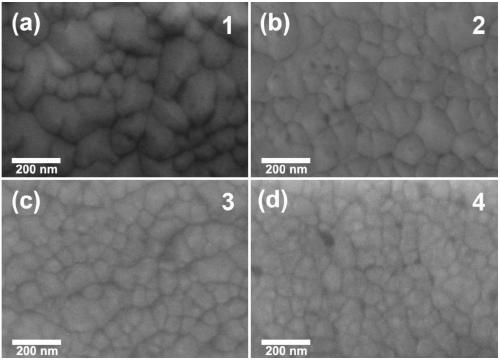

[0052] 3. Alternate sputtering deposition of monolayer crystalline Hf coating and amorphous Si 3 N 4 Coating, preparation of Hf / Si 3 N 4 Multi-layer structural coating.

[0053] (1) DC sputtering deposition of single-layer metal Hf coating. After confirming that the ambient temperature of the cavity is 200°C and the temperature of the magnesium alloy substrate is 350°C, perform the following operations: adjust the Ar flow rate to 70.0sccm, adjust the chamber pressure to 0.45Pa; turn the sample stage to face the Hf metal target, both The distance is 15.0cm; set the Hf target DC sputtering power to 250W, open the ta...

Embodiment 3

[0061] 1. Substrate pretreatment

[0062] (1) Mechanical grinding and polishing treatment, same as embodiment 1.

[0063] (2) chemical etching, same as embodiment 1.

[0064] (3) The ion source bombardment cleaning treatment is the same as that in Embodiment 1.

[0065] 2. Metal Hf, pure Si 3 N 4 The pre-sputtering of the target is the same as in Example 1.

[0066] 3. Alternate sputtering deposition of monolayer crystalline Hf coating and amorphous Si 3 N 4 Coating, preparation of Hf / Si 3 N 4 Multi-layer structural coating.

[0067] (1) DC sputtering deposition of single-layer metal Hf coating. After confirming that the ambient temperature of the cavity is 200°C and the temperature of the magnesium alloy substrate is 350°C, perform the following operations: adjust the Ar flow rate to 70.0sccm, adjust the chamber pressure to 0.45Pa; turn the sample stage to face the Hf metal target, both The distance is 15.0cm; set the Hf target DC sputtering power to 200W, open the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com