Coexistence of highly conductive and corrosion-resistant amorphous/nanocrystalline composite coating and its preparation method and application

A technology of coating and electric current, applied in the direction of coating, nanotechnology, nanotechnology, etc., can solve the problems of high price, affecting battery power, stability and life, and achieve no columnar defects, excellent corrosion resistance and protection performance, deposition The effect of high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Specifically, as an aspect of the technical solution of the present invention, a method for preparing a highly conductive and corrosion-resistant amorphous / nanocrystalline composite coexisting coating involved includes:

[0030] Provide metal base;

[0031] Using arc ion plating composite high-power pulsed magnetron sputtering technology, Cr target is used as arc target, Al target is used as high-power pulsed magnetron sputtering target, and methane is used as working gas to deposit on the surface of the metal substrate to form Cr- Al-C layer;

[0032] and, performing vacuum low-temperature heat treatment on the metal substrate deposited with the Cr-Al-C layer to obtain a highly conductive and corrosion-resistant amorphous / nanocrystalline composite coexisting coating;

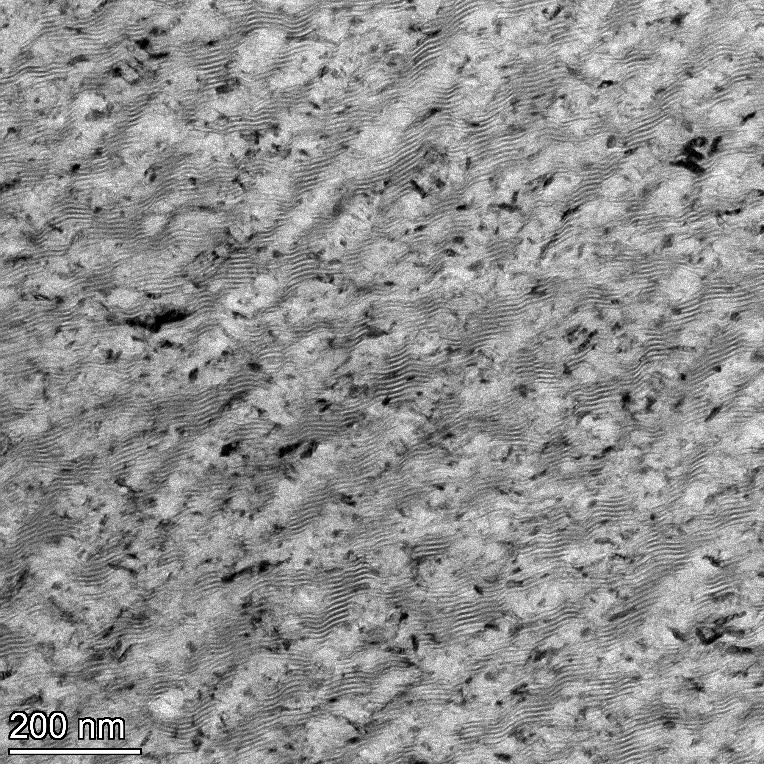

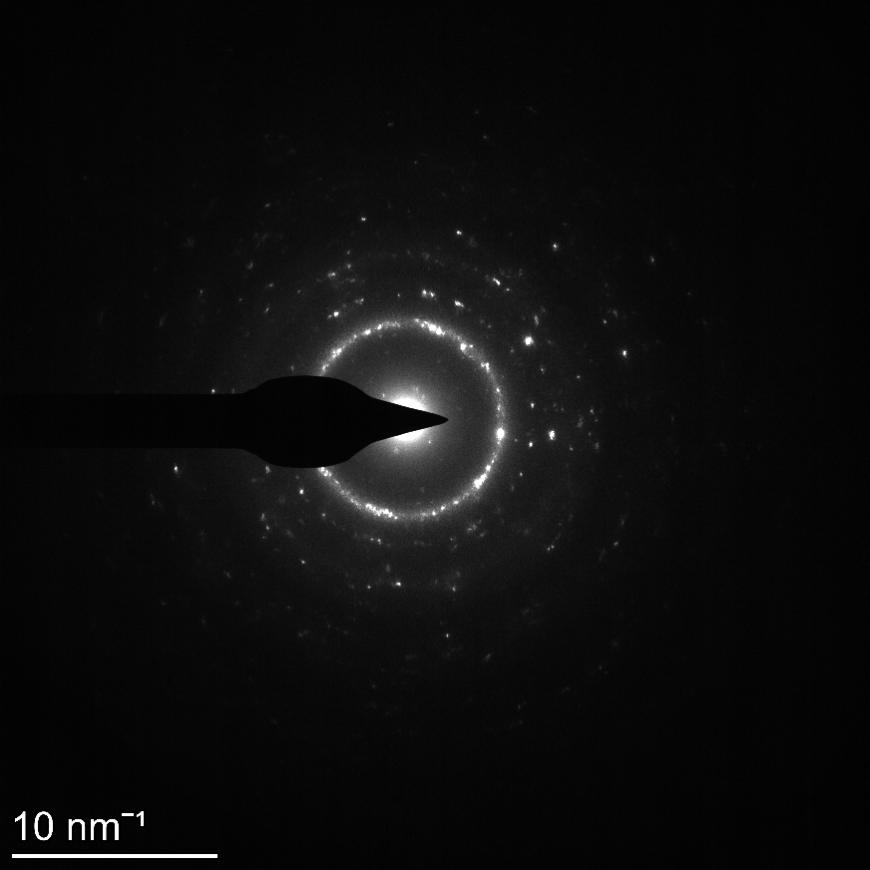

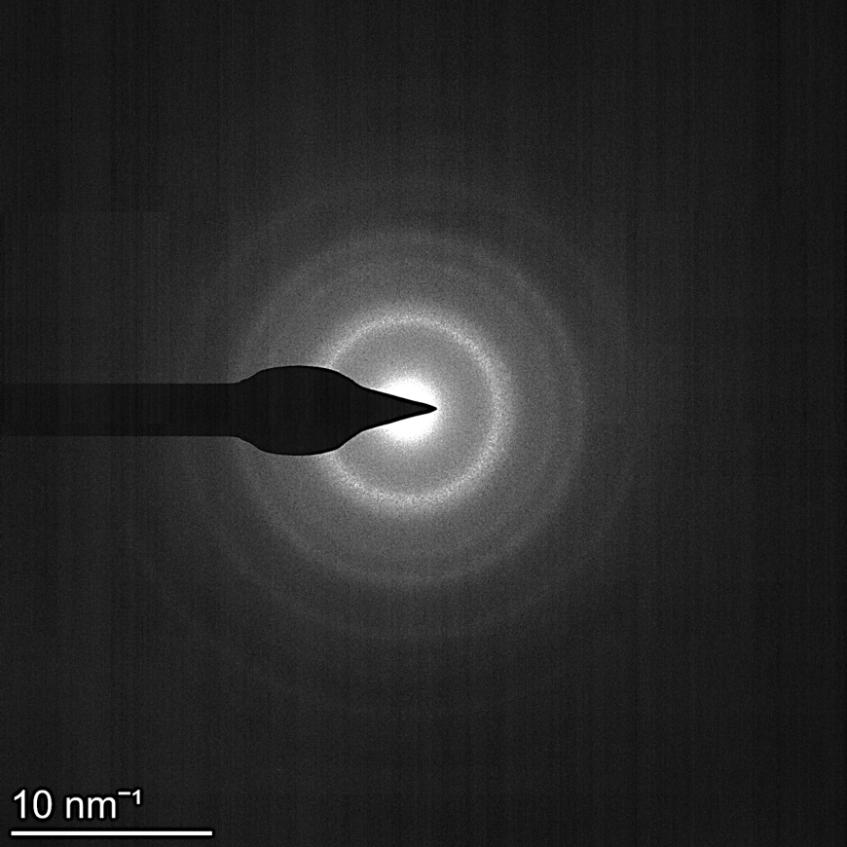

[0033] The coating has an amorphous structure and a nanocrystalline structure, the amorphous structure is a thick striped structure, and the amorphous structure is Cr-Al-C; the nanocrystalline structure...

Embodiment 1

[0051] In this embodiment, the substrate is a 316L stainless steel bipolar plate used in a proton exchange membrane fuel cell, and the Cr-Al-C / Cr on the surface of the substrate is 2 The preparation method of AlC coating is as follows:

[0052] (1) Put the 316L stainless steel bipolar plate substrate after cleaning, degreasing and drying into the cavity, and wait until the vacuum pressure in the cavity is 3.0×10 -5 Below Torr, 180sccm of argon gas was introduced into the vacuum chamber, the substrate bias was -60V, the linear anode ion source current was set to 0.8A, and the substrate was etched with ionized argon ions for 60min.

[0053] (2) Using arc ion plating composite high-power pulsed magnetron sputtering technology, using Cr target as the arc target, the current of the arc target is 40A, using the Al target as the high-power pulsed magnetron sputtering target, the high-power pulse duty cycle is 25%, the average sputtering power of the Al target is 2500W, the target di...

Embodiment 2

[0064] In this embodiment, the substrate is a 304 stainless steel bipolar plate used for proton exchange membrane fuel cells, and the Cr-Al-C / Cr on the surface of the substrate is 2 The preparation method of AlC coating is as follows:

[0065] (1) Put the 304 stainless steel bipolar plate substrate after cleaning, degreasing and drying into the cavity, and wait until the vacuum pressure in the cavity is 3.0×10 -5 Below Torr, 150sccm of argon gas was introduced into the vacuum chamber, the substrate bias was -90V, the linear anode ion source current was set to 0.8A, and the substrate was etched with ionized argon ions for 60min.

[0066] (2) Using arc ion plating composite high-power pulsed magnetron sputtering technology, using Cr target as the arc target, the current of the arc target is 40A, using the Al target as the high-power pulsed magnetron sputtering target, the high-power pulse duty cycle is 35%, the average sputtering power of the Al target is 3000W, the target dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com