A Method for Improving Uniformity During Spray Electrodeposition Processing

A spray electrodeposition, processing technology, applied in the field of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

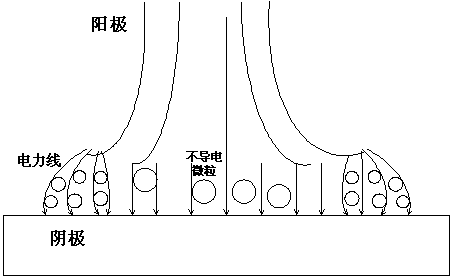

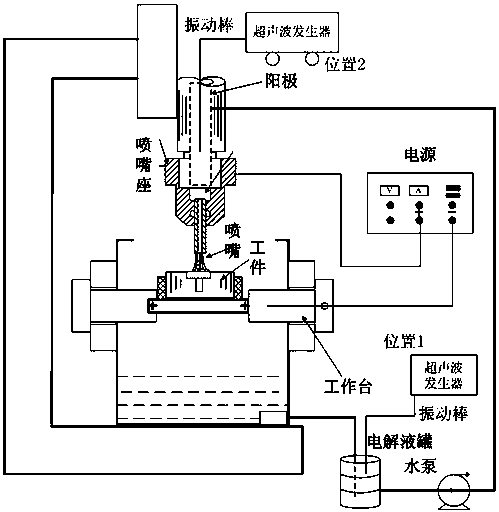

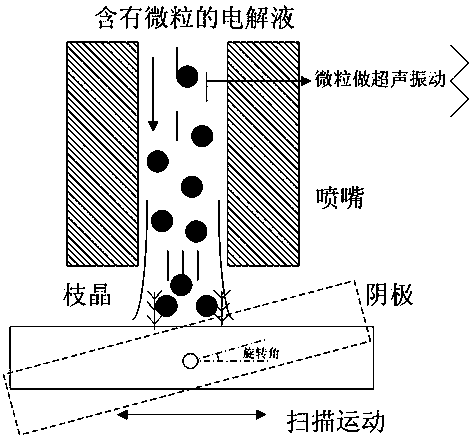

Method used

Image

Examples

Embodiment approach

[0039] The present invention provides the following specific implementation methods: Embodiment 1: 1) Substrate surface pretreatment. In order to obtain better bonding force and smooth and fine coating, the following pretreatment procedures are required: ① Polishing treatment: first use 400-mesh metallographic sandpaper to polish the surface of the substrate such as a stainless steel substrate to remove its oxide layer, and then use 800, 1000-mesh gold Grinding and polishing with sandpaper to ensure that the surface of the substrate reaches a certain roughness; ②Surface cleaning: Clean the surface of the substrate with distilled water, and then soak and scrub with acetone for about 5 minutes for degreasing treatment. ③Surface etching treatment: Put the stainless steel substrate in 10% dilute sulfuric acid solution for 5 minutes for passivation treatment; ④Clean with distilled water and dry it for later use.

[0040] 2) Configure the electrolyte. The composition and process pa...

Embodiment 2

[0049] Embodiment two: the size of the test piece stainless steel plate 1Cr18Ni9Ti is 100mm * 10mm * 1mm, and the electrodeposition equipment processing method is used to prepare the copper deposition layer on the surface, and its operation steps are as follows:

[0050] 1) Surface treatment of stainless steel 1Cr18Ni9Ti, followed by polishing, degreasing, passivation, washing and drying.

[0051] 2) Configure the electrolyte. The composition and process parameters of the electrolyte in the present embodiment are respectively:

[0052] CuSO 4 ·5H 2 O 250g / L, 98% concentrated sulfuric acid 50g / L, electrolyte temperature 25°C. The electrolyte solution is prepared with analytical pure or chemical pure reagents plus distilled water.

[0053] 3) The particles mixed in the electrolyte are micron alumina particles with a particle size of 10 microns and a purity greater than 99.99%. Do particle pretreatment before processing.

[0054] 4) Electrodeposition parameters are selected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com