A kind of method for preparing magnesium phosphate/super-p composite corrosion-resistant coating

A magnesium phosphate, corrosion-resistant technology, applied in coating, phosphating, electrolytic coatings, etc., can solve the problems of thin coating thickness, poor adhesion between coating and base material, low corrosion resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Prepare the sample NdFeB, the sample size is: 10mm×10mm×5mm.

[0024] (2) Alkali washing and degreasing and process conditions: sodium hydroxide 3g / L, sodium carbonate 30g / L, sodium phosphate 50g / L, op-10 emulsifier 0.5g / L, the rest is water, the temperature is 30 ℃, the treatment Time 30s.

[0025] (3) Pickling rust removal and process conditions: Immerse the degreasing and water-washed sample into a mixture containing 3% nitric acid and 3% sulfuric acid, and the rest is water; the temperature is room temperature, and the time is 10s.

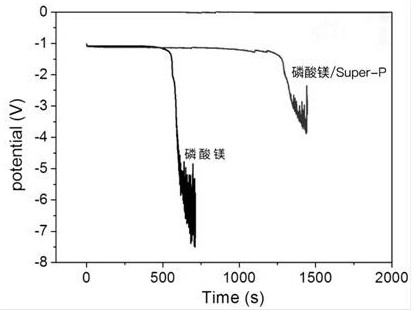

[0026] (4) Electroplating solution components and process conditions: magnesium oxide 2g / L, phosphoric acid 10g / L, Super-P 200mg / L, surfactant 50mg / L, deionized water 200ml, pH value 4.4, current density 5mA / cm 2 , the time is 20min, and the temperature is 50°C.

[0027] (5) Rinse with clean water after electrodeposition and dry with a hair dryer.

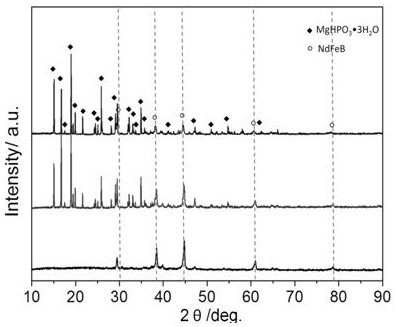

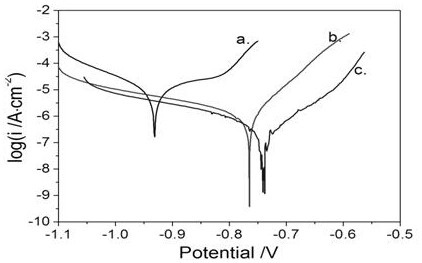

[0028] The coating obtained in this embodiment is bright gray, uniform in color...

Embodiment 2

[0030] (1) Prepare the sample NdFeB, the sample size is: 10mm×10mm×5mm;

[0031] (2) Alkaline cleaning and degreasing and process conditions: sodium hydroxide 5g / L, sodium carbonate 35g / L, sodium phosphate 60g / L, op-10 emulsifier 1g / L, the rest is water, the temperature is 30°C, and the processing time 40s;

[0032] (3) Pickling rust removal and process conditions: Immerse the degreasing and water-washed sample into a mixture containing 3% nitric acid and 3% sulfuric acid, and the rest is water; the temperature is room temperature, and the time is 15s;

[0033] (4) Plating solution components and process conditions: magnesium oxide 2g / L, phosphoric acid 10g / L, Super-P 200mg / L, surfactant 50mg / L, deionized water 200ml, pH value 4.5, current density 5mA / cm 2 , the time is 20min, and the temperature is 60°C.

[0034] (5) Rinse with clean water after electrodeposition and dry with a hair dryer.

[0035] The obtained coating is bright gray, uniform in color, relatively dense, ...

Embodiment 3

[0037] (1) Prepare the sample NdFeB, the sample size is: 10mm×10mm×5mm;

[0038] (2) Alkaline cleaning and degreasing and process conditions: sodium hydroxide 7g / L, sodium carbonate 40g / L, sodium phosphate 70g / L, op-10 emulsifier 1.5g / L, the rest is water, the temperature is 40 ℃, the treatment time 50s;

[0039] (3) Pickling rust removal and process conditions: Immerse the degreasing and water-washed sample into a mixture containing 3% nitric acid and 3% sulfuric acid, and the rest is water; the temperature is room temperature, and the time is 20s;

[0040](4) Electroplating solution components and process conditions: magnesium oxide 3g / L, phosphoric acid 15g / L, Super-P 250mg / L, surfactant 55mg / L, deionized water 200ml, pH value 4.5, current density 5mA / cm 2 , the time is 15min, and the temperature is 70°C.

[0041] (5) Rinse with clean water after electrodeposition and dry with a hair dryer.

[0042] The obtained coating is bright gray, uniform in color, very dense, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com