Dual ultrasonic-assisted laser-CMT composite welding system and welding method

An ultrasonic-assisted, hybrid welding technology, applied in laser welding equipment, welding/welding/cutting items, welding equipment, etc., can solve the problems of large loss of reinforcement phase, affecting weld quality, reducing joint performance, etc., to achieve molten pool adhesion Effects of improved hysteresis, simple welding process, and reduced number of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

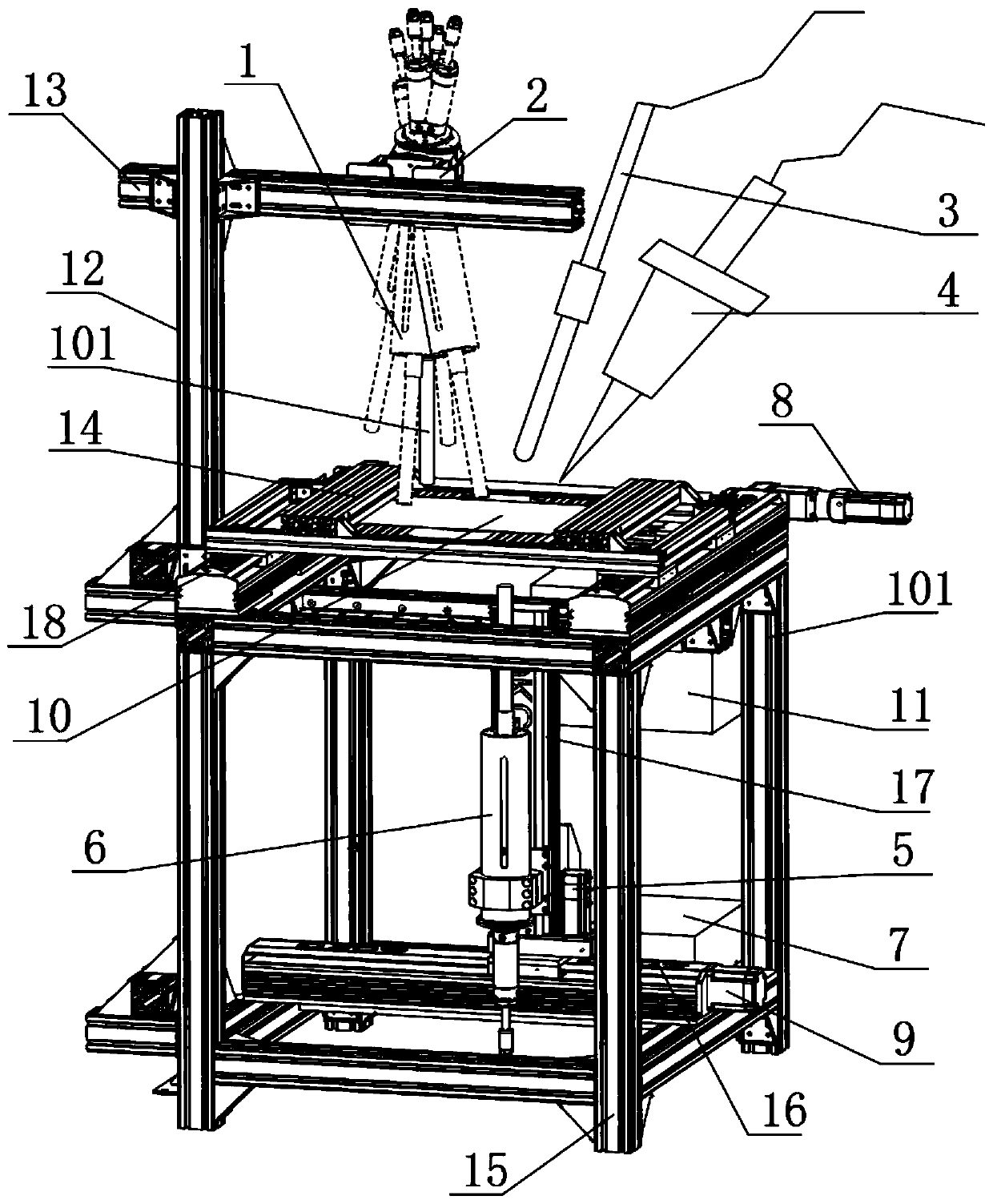

Embodiment 1

[0050] The specific steps are:

[0051] Pre-welding treatment steps for aluminum-based composite materials: Before welding, open a single-side 30°V-shaped groove, leave a 0.5mm blunt edge, polish the groove and its vicinity with sandpaper to remove scale, and use acetone to ultrasonically clean it for 10 minutes;

[0052] Parameter setting: the workpiece 10 is a SiC reinforced aluminum matrix composite material with a volume fraction of 17%, the size is 160*80*4mm, and it is placed on the workbench 14. The running speed of the workbench 14 is set to 1m / min, and the fiber laser 4 adopts a continuous laser. The laser power and defocus are 1000W and 15mm respectively, the welding current of CMT welding machine 3 is set to 80A; use the upper ultrasonic mechanism 1, and adjust the distance d1 and θ to 10mm and 20° respectively, the ultrasonic power is 800W, and the ultrasonic cylinder The pressure is 0.25MPa;

[0053] The workpiece 10 is fixed with a special fixture, leaving a gap...

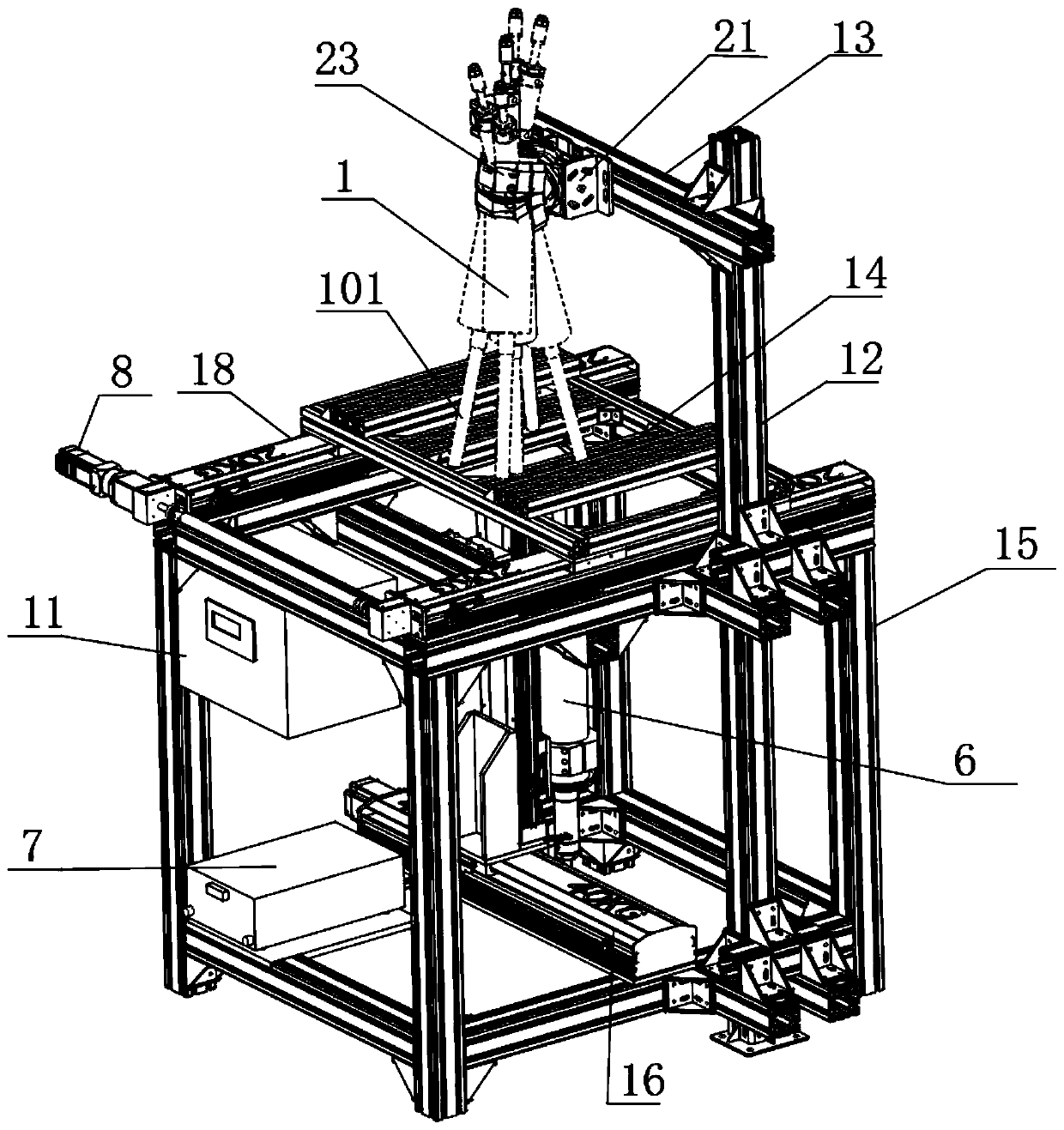

Embodiment 2

[0056] The specific steps are:

[0057] Pre-welding treatment steps for aluminum-based composite materials: Before welding, open a single-side 30°V-shaped groove, leave a 0.5mm blunt edge, polish the groove and its vicinity with sandpaper to remove scale, and use acetone to ultrasonically clean it for 10 minutes;

[0058] Parameter setting: the SiC reinforced aluminum matrix composite material with a volume fraction of 20% has a size of 160*80*6 mm and is placed on the workbench 14. The running speed of the workbench is set to 1m / min. The focal weight is 1000W and 15mm respectively, the welding current of CMT welding machine 3 is set to 100A; the lower ultrasonic mechanism 6 is adopted, and the distance d2 and θ are adjusted to 10mm and 0° respectively, the ultrasonic power is 800W, and the ultrasonic cylinder pressure is 0.3MPa ;

[0059] The workpiece 10 is fixed with a special fixture, so that there is a 1mm gap in the groove, and the shielding gas is 99.999% pure Ar. Befo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overall length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com