Yarn matching method for polyester-nylon interwoven hollow fabric

A technology of fabric and polyester nylon, which is applied in the yarn matching field of polyester and nylon interwoven hollow fabrics, which can solve the problems of long cycle, waste of financial resources and storage, and can only be placed in warehouses, etc., to achieve small loss of physical properties, smooth mesh, and not easy to wrinkle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A yarn matching method for polyester-nylon interwoven hollow fabrics, which uses a dry-drying method to test the dry heat shrinkage of nylon fiber yarn and polyester fiber yarn respectively, takes a fixed-length sample and heats it to 175°C, and measures the length of each sample after baking for 30 minutes , and calculate the dry heat shrinkage of each sample, the calculation formula of dry heat shrinkage is (original length before dry heat - length after dry heat) / original length before dry heat × 100%, choose dry heat shrinkage ≤ 4.5% and close to High-quality nylon yarn and polyester yarn are used as raw material yarns for fabrics.

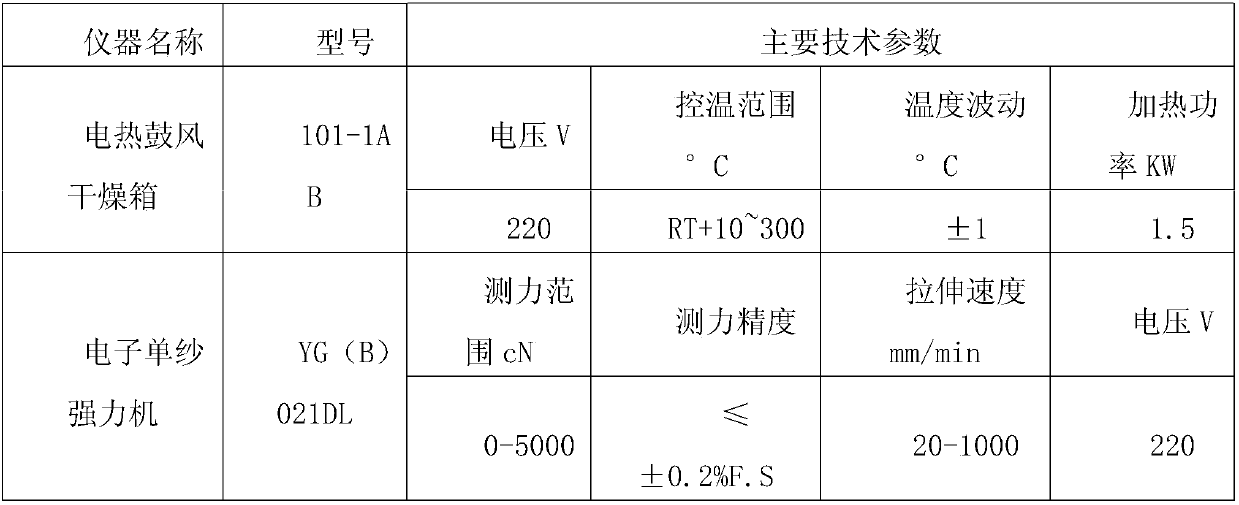

[0016] The equipment used is as follows

[0017]

[0018] The measured data are as follows:

[0019] No. 1 sample - test results of 140D nylon fiber yarn in a chemical fiber factory

[0020] Test items

unit

Test Results

cN / dtex

4.06

elongation at break

%

39.5

Dry ...

Embodiment 2

[0033] It is basically the same as Example 1, the difference is that the dry heat wet recovery rate of nylon fiber filaments is also measured and calculated, and the fixed-length samples are heated to 175°C, and the length of each sample is measured after baking for 30 minutes, and then the dry heat After dipping the sample in water, measure the length after dipping in water, and calculate the recovery rate of dry heat dipping in water. The formula for calculating the recovery rate of dry heat dipping in water is (length after dipping in water-length after dry heat) / length after dry heat×100 %, choose nylon yarn with dry heat wet recovery rate ≤ 3.5%. Specifically, select the average value of 6 1000 mm nylon fiber filaments for testing. Put it into a dry heat oven set at 175 degrees, dry for 30 minutes, take out the nylon fiber filament, measure its length, if it is 955 mm, the dry heat shrinkage rate is 4.5%, and the nylon fiber with a length of 955 mm After sticking to wate...

Embodiment 3

[0040]It is basically the same as Example 1, the difference is that the dry heat strength loss rate of all samples is also detected and calculated, and the steps include: (1) sampling the chemical fiber to be tested, carrying out the tensile performance test according to the GB / T14344 standard, and detecting at normal temperature Obtain the breaking strength; (2) Take an equal amount of sample, put it into an electric blast drying oven, heat it to 175°C, and bake it for 30 minutes; (3) Take out the sample after baking, and measure the strength after dry heat; (4 ) Calculate the loss rate of dry heat strength and select yarns with a loss rate of dry heat strength≤30%, the formula for calculating the loss rate of dry heat strength is (breaking strength-strength after dry heat) / breaking strength×100%.

[0041] Detecting result is the same as embodiment one, and yarn matching is as follows:

[0042] The dry heat strength loss rate of No. 1 sample and No. 4 sample were 62.1% and 27...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com