Prefabricated assembly type shear wall having damping function

A prefabricated shear force and prefabricated assembly technology, applied in protective buildings/shelters, building components, earthquake resistance, etc., can solve the problems of irreparable, no energy dissipation and shock absorption parts, etc., to improve the seismic performance and simple structure , Good energy dissipation and shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

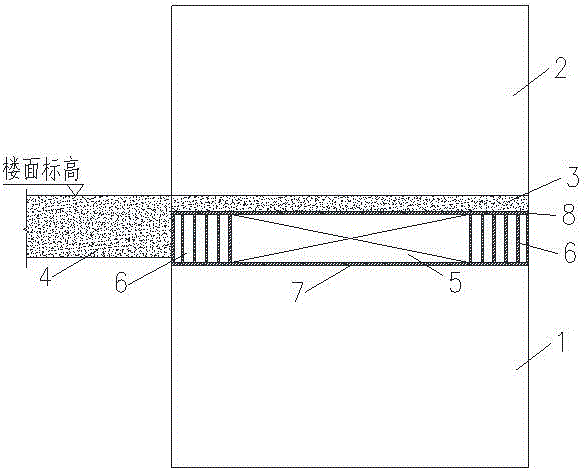

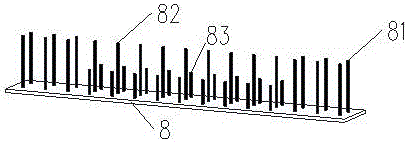

[0013] See attached figure 1 , The present invention consists of the lower floor prefabricated shear wall 1, the upper floor prefabricated shear wall 2, the cast-in-place ring beam 3, the cast-in-place connecting beam 4, the shear type mild steel damper 5, the edge steel structure 6, the lower connecting plate 7. And the upper connecting plate 8. The lower floor prefabricated shear wall 1 and the upper floor prefabricated shear wall 2 are factory-prefabricated concrete members; the cast-in-place ring beam 3 and the cast-in-place connecting beam 4 are cast-in-place concrete members; the shear type soft The steel damper 5 adopts the mild steel damping of the wall support structure, and the shear-type mild steel damper 5 is located in the shear wall area outside the edge steel structure 6, and dissipates energy through metal yield under the action of an earthquake.

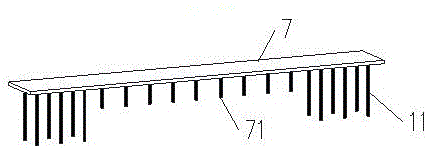

[0014] See attached figure 2 The lower connecting plate 7 is used to connect the lower floor shear wall 1 with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com