Method for automatically controlling yaw damping of wind power unit

A wind turbine, yaw technology, applied in the direction of engine, wind power generation, engine control, etc., can solve the problems of yaw damping can not be automatically adjusted, high failure rate, inconvenient maintenance, etc., achieve real-time optimal system performance, avoid abnormal noise , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Combine below Attached picture , the present invention will be described in further detail.

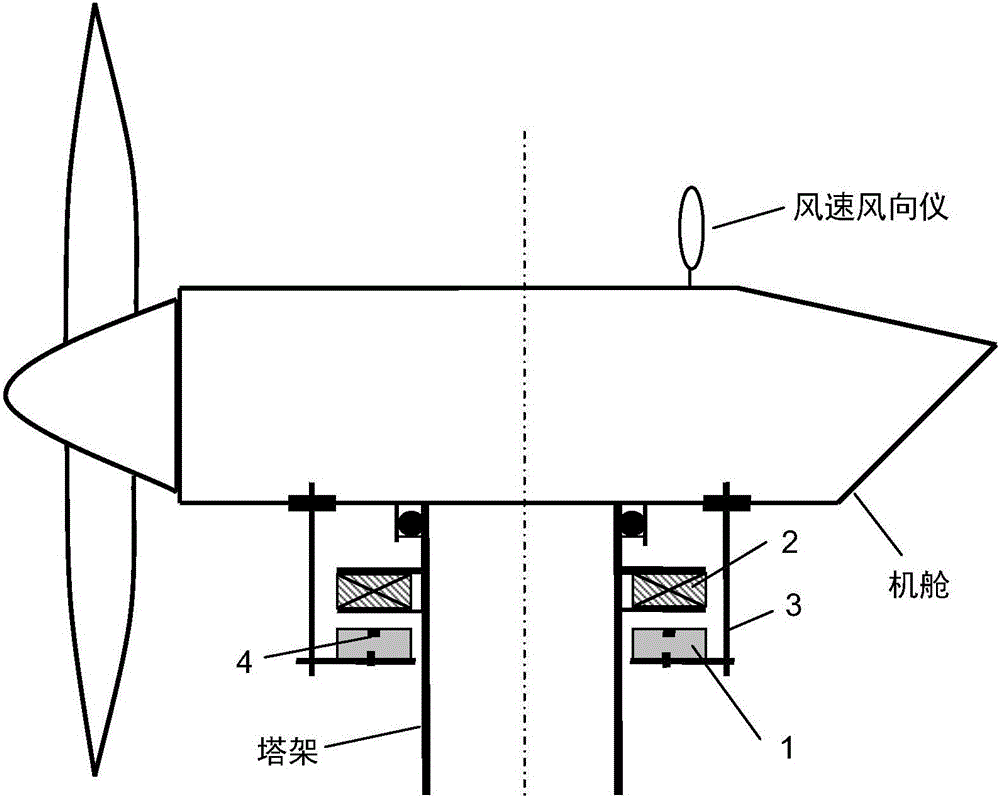

[0035] Such as picture 1 As shown, the magnetic suspension yaw system includes a yaw motor, a suspension bracket 3, an air gap sensor 4, and an anemometer. The yaw motor is a disc synchronous motor, which includes a rotor 1 and a stator 2. Winding, the stator 2 has a three-phase winding. The rotor 1 is fixed to the nacelle through the suspension bracket 3, that is, one end of the suspension bracket 3 is fixed to the rotor 1 with bolts, and the other end is fixed to the nacelle; the stator 2 is fixed on the tower. The air gap sensor 4 is used to detect the length of the air gap between the rotor 1 and the stator 2 .

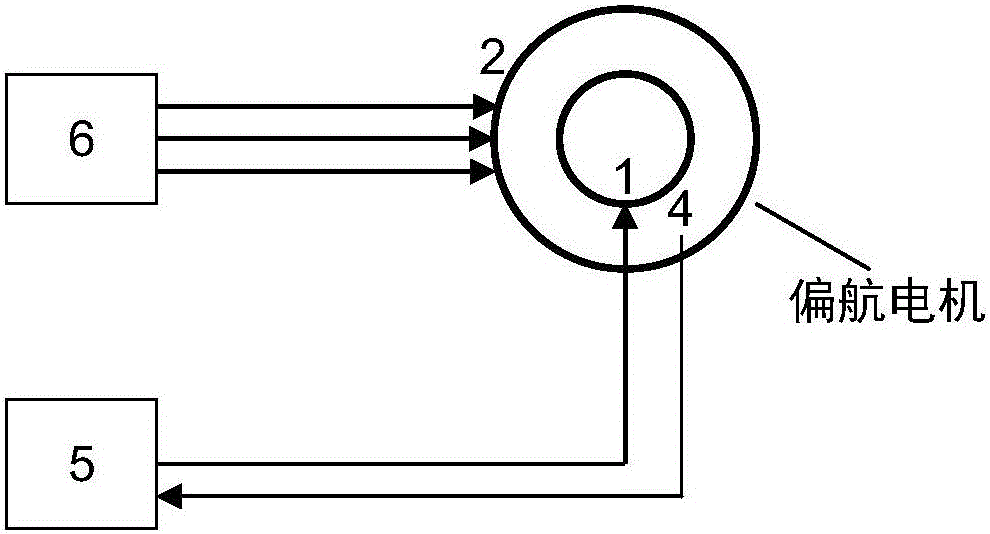

[0036] Such as picture 2 As shown, the rotor 1 and the air gap sensor 4 are connected to the rotor controller 5 , and the stator 2 is connected to the stator controller 6 .

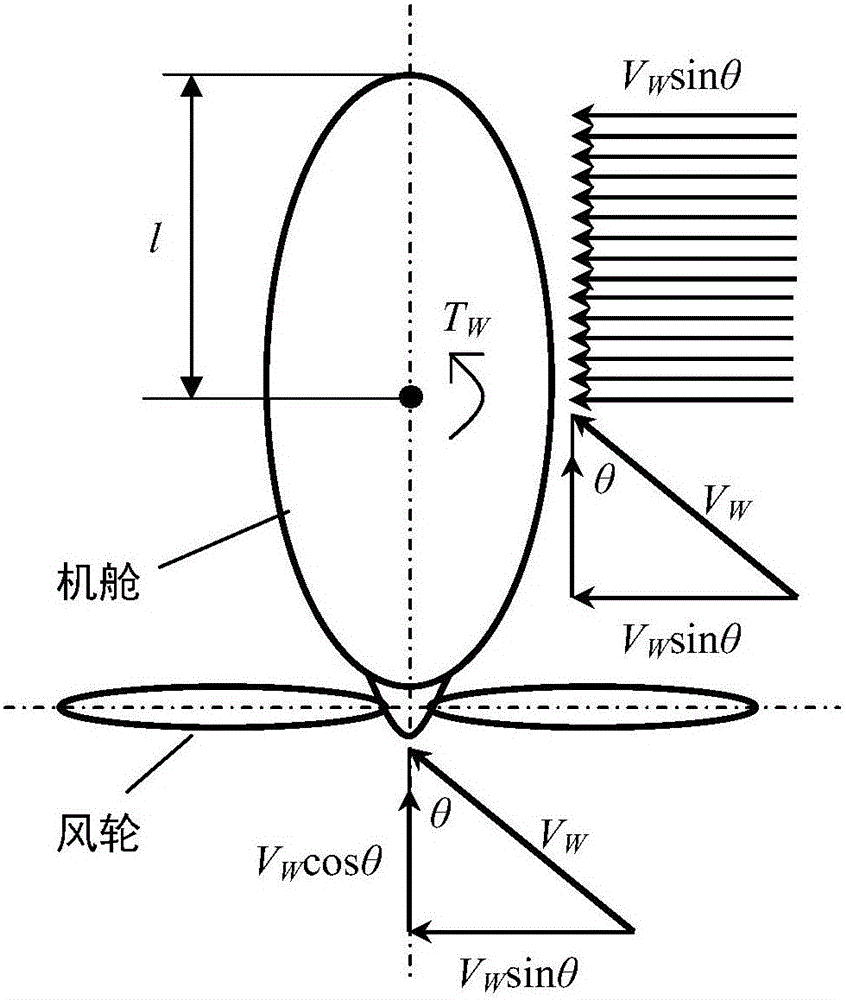

[0037] A method for automatically adjusting the yaw damping of a wind turbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com