Preparation method of transmission electron microscope sample with large area of thin region

A technology for transmission electron microscope samples and electron microscope samples, which is applied in the field of preparation of large-area thin area samples, can solve the problems of discontinuous thin area of samples, expensive equipment, high cost, etc., and achieve the effect of eliminating incomplete surface of samples and controlling the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further description will be given below through examples and in conjunction with the accompanying drawings.

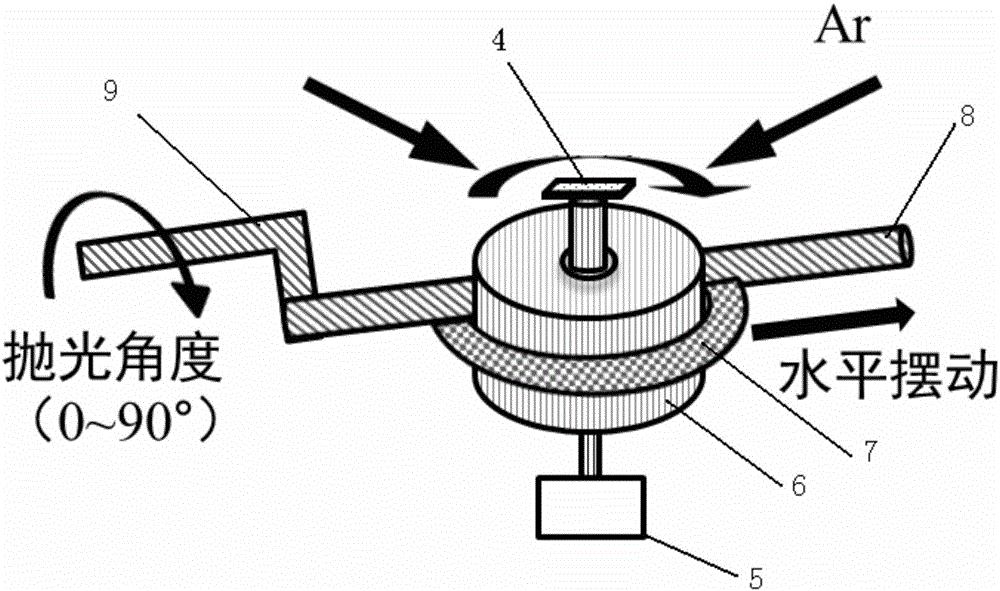

[0024] This example is based on Figure 4 The preparation process shown is for the preparation of large-area TEM samples, and the specific steps include:

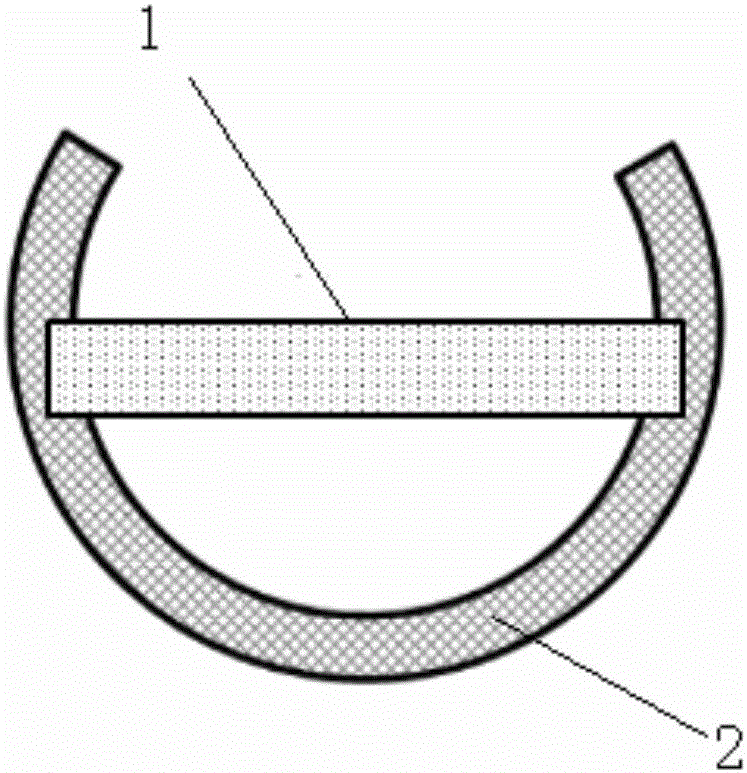

[0025] (1) Cutting and processing of samples: First, cut the material samples to be tested into strips with length × width × height about 2.8 × 1 × 1 mm, stick them on the glass slide with paraffin, and place them in a fixture with a particle size of 30 μm in turn. , 10μm, 5μm, 1μm type sandpaper to polish the sample to less than 200μm, and glue the polished sample to the semicircular copper ring with AB glue, such as figure 1 shown;

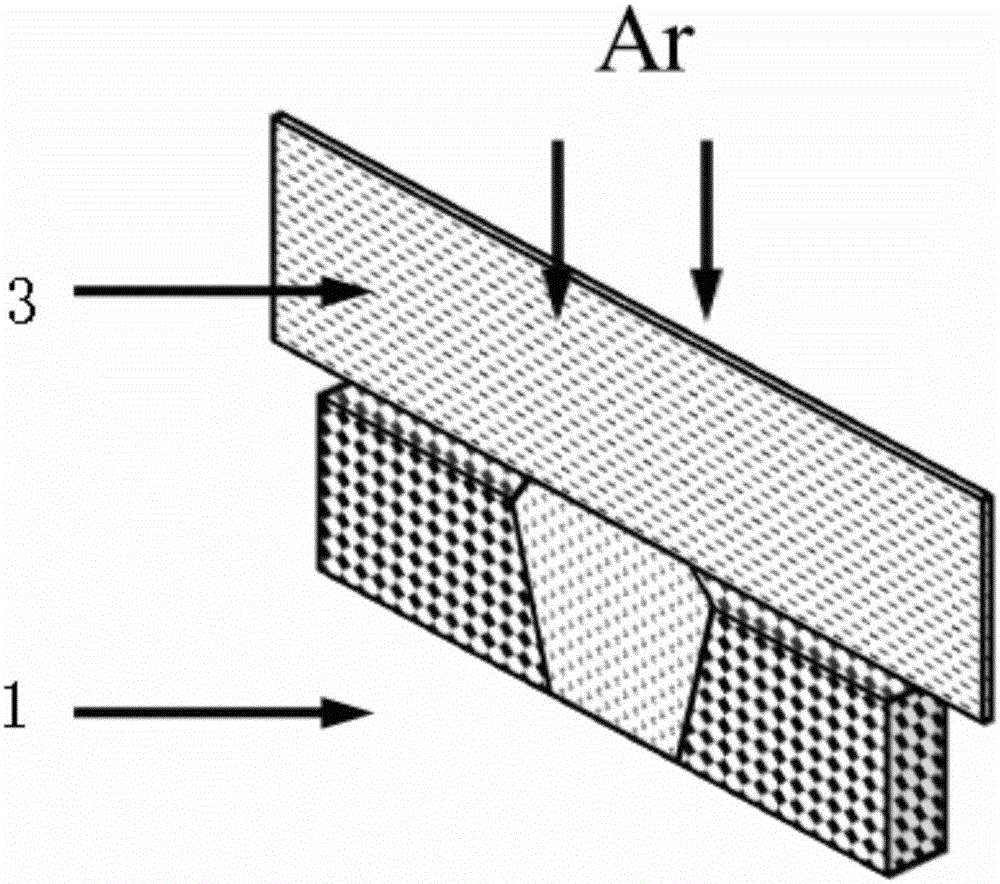

[0026] (2) Ion cutting the sample: put the copper ring with the sample on the sample stage of the ion slicer, and the pre-vacuum degree is better than 1×10 -4 Pa, make the argon ion beam and the sample plane at zero degree for ion cutting, there is a belt between the ion bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com