Ultrahigh vacuum sample storage and transfer platform

A sample storage and ultra-high vacuum technology, applied in the direction of analytical materials, instruments, etc., can solve problems such as complex operation and sample contamination, and achieve the effects of improving growth efficiency, preventing pollution, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

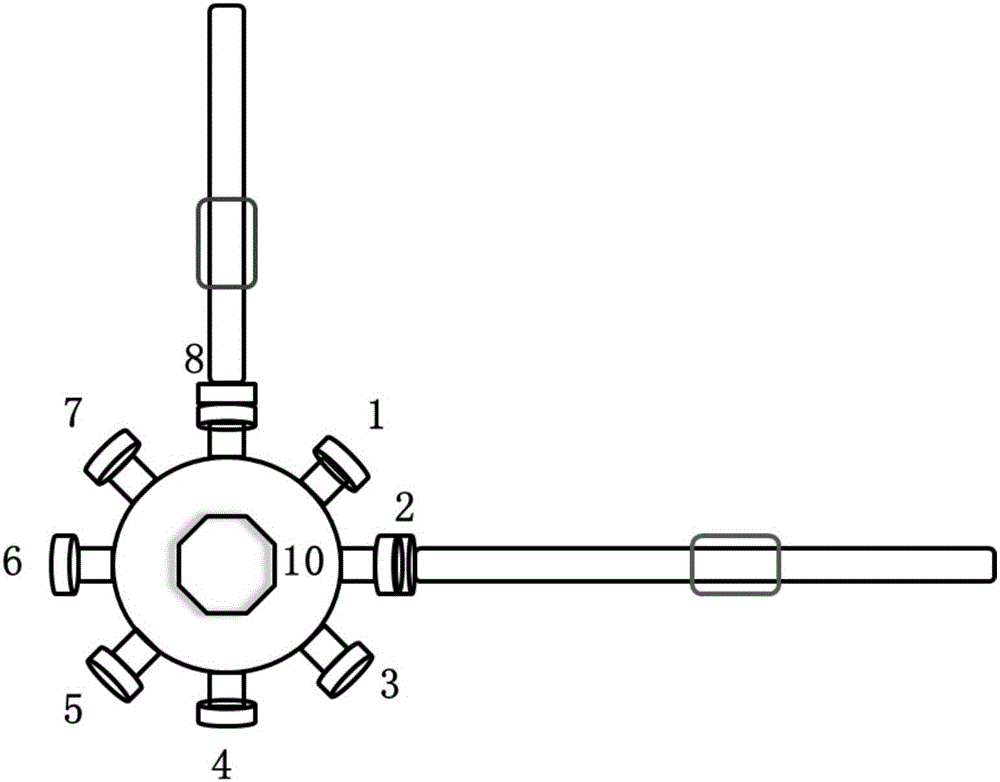

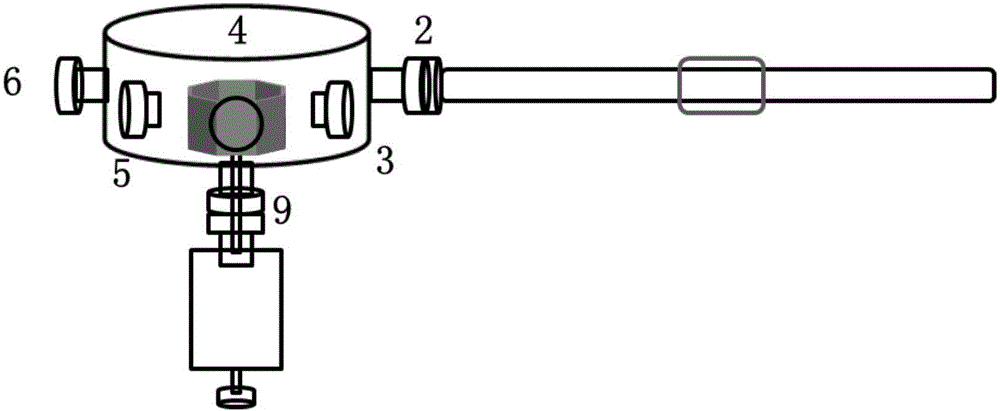

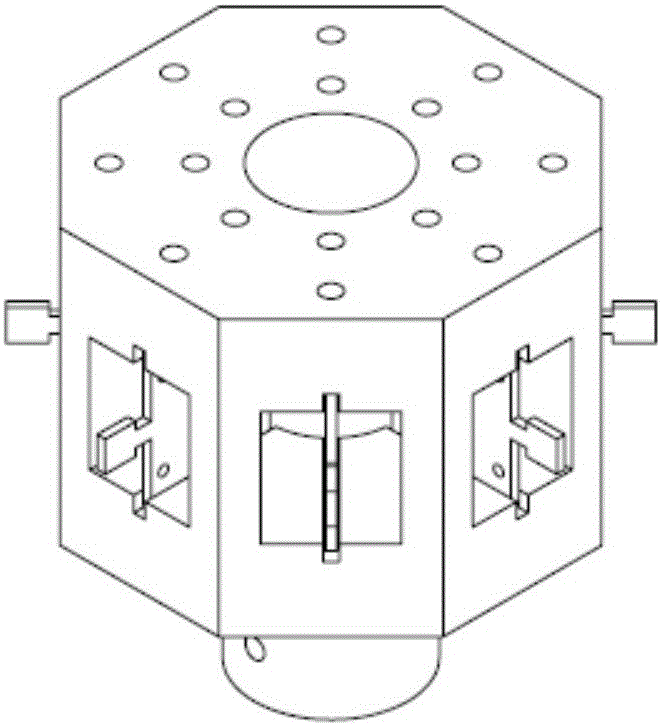

[0030] As shown in the figure, the present invention provides a connection platform for transferring and storing samples between different ultra-high vacuum systems, and the labels of the first to ninth flanges are 1, 2, 3, 4, 5, 6, 7, 8, 9; the platform connects two sets of systems at the same time through the gate valve and the second gate valve connected to the fourth flange 4 and the sixth flange 6. At the same time, the storage and transfer of samples between the two systems is realized through the magnetically driven transmission rod and the sample storage platform connected to flange 2 (the second flange, and so on) and flange 8 .

[0031] figure 1 A top view of an overall structure according to an embodiment of the invention is shown. In this embodiment, a group of (8) samples are loaded into the ultra-high vacuum sample storage and transfer platform through the quick opening device, and then the ultra-high vacuum sample storage and transfer platform is maintained at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com